Speed and efficiency go hand in hand with the Mooney M20-series airframe. But bolt on a high-flying turbocharged engine and the performance gets kicked up several notches. These days there is tight competition in the used turbocharged single market—mainly from Cirrus, a company that’s been hugely successful with the fixed-gear turbo SR22T. And though Mooney has stopped cranking out new airplanes, and the future is unknown, owners love their 231 and 252s for the same reasons they always have, accepting the potential for more upkeep than normally aspirated 201 models.

It took a bit for Mooney to get the M20K worked out. It didn’t get the turbocharging system right on the first try and the model developed a reputation as a maintenance hog. At this point that reputation has been mostly burnished and the fact that the M20K bores along between 160 and 200 knots on relatively little fuel has boosted the model’s appeal.

But that turbocharged engine can still be a maintenance hog, and with a single door and small cabin, it may not be the airplane for the flexibly challenged. But those are accepted warts that have always tagged along with a Mooney. Bottom line: If cruising fast and miserly is your goal, the M20K models—the 231, the 252 and the Encore—are worth a look. In our research in the fall of 2022, we found that prices are way up, and upgraded and well-maintained models are premium priced.

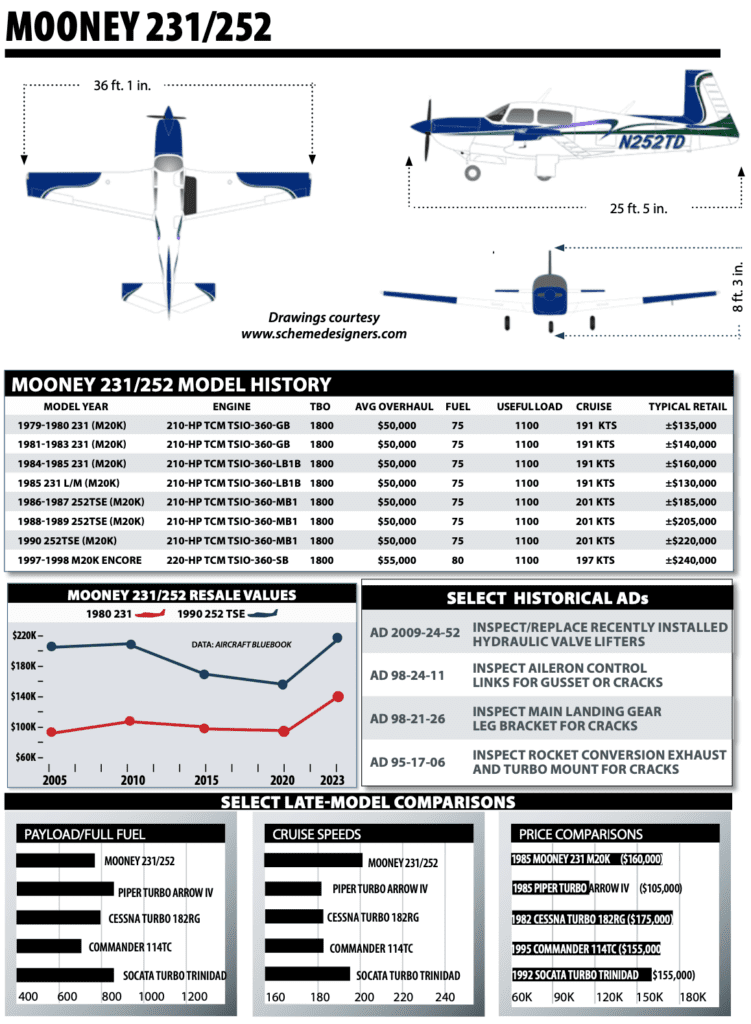

MODEL HISTORY

Mooney came into the turbocharging game relatively late compared to other manufacturers. In 1966, Cessna pioneered the market with the T210 and made a strong showing in the single-engine, high-altitude market. Beech brought out the V35TC in 1966, but it was never as strong a seller as the A36. Mooney wasn’t completely flat-footed during the 1960s, introducing the 310-HP M22 Mustang in 1967, a big brute of an airplane that to some was as ugly as it was unsuccessful.

Through the 1970s, Mooney did we’ll with efficient airplanes powered by Lycoming four-bangers. Mooney’s big breakthrough came in 1977, when the M20J 201 was introduced as the fruit of a clever Roy LoPresti-led aerodynamic cleanup of the venerable F model. The 201—named for its maximum speed in miles per hour—marked a turning point for Mooney, even if the claimed speed was somewhat optimistic.

As early as 1977, Piper had the Turbo Arrow and Mooney realized it needed to compete in this market. The result appeared in 1979 as the 231—again, named for its top speed—or M20K. It was essentially a 201 with a six-cylinder, 210-HP Continental TSIO-360-GB in place of the 201’s 200-HP Lycoming IO-360. The airframe had a lot going for it. It was strongly built of welded 4130 steel, the gear system was all but indestructible and the handling was mannerly, easily flown by a pilot with minimal retract experience. By modern standards, Mooney had a smash hit on its hands. It sold 246 airplanes the first year, outdistancing the 201 by nearly two to one. The fact that the two airplanes were so similar simplified the build process and likely made the project profitable from the first year.

The differences are in minor aerodynamic refinements. The K model’s fuel capacity is 10 gallons more than the J model, and both empty and gross weights are 160 pounds higher. Design-wise, the 231 was exactly what the buyers were looking for: a turbocharged 201.

But if buyers were hoping for the 201’s excellent dispatch rate, they got something less. Problems with the 231’s Continental engine were several-fold and hurt the model’s initial reputation. The new cowling didn’t cool the engine adequately, the fixed-wastegate turbo required constant attention and was easy to

mismanage, overboosting and high heat put undue stress on the engine, and it was prone to cracking cylinders and cases. The connecting rods were prone to failure and the original magnetos were unpressurized, and would arc at high altitude. On top of all this, the TBO of the first engines was a miserly 1400 hours, later upped to 1800 hours, where it still stands. Even with all these faults—and they were considerable—some owners achieved impressive maintenance reliability by obsessive attention to operating technique. Specifically, that meant careful leaning and attention to cowl flaps and preventive maintenance of the turbo. But not all owners were so careful and premature engine crumps were common.

IMPROVEMENTS

With a couple of years of experience under its belt, Mooney undertook some improvements, adding a split rear cargo seat in 1982, while in 1984, a new variant of the engine—the LB1B, which is approved as a replacement for the GB—was introduced with better cooling and overboost protection. Mooney also included some aerodynamic tweaks that added 3 to 5 knots: sealed nosegear doors, a belly pan, a more streamlined tailcone and removal of one of the vent intakes. The alternate air intake system changed to address reports of icing-induced power loss.

While these fixes certainly helped, the improvements were hardly night and day. By 1986, further retooling produced the 252TSE for Turbo Special Edition. The 252, while still an M20K, is significantly different from the 231. Another variant of the engine was fitted, the -MB1. The induction and cooling systems were reworked and a new intercooled, density-controlled, variable wastegate AiResearch turbocharger replaced the original, fixed wastegate Rajay/Rotomaster unit. Other changes included infinitely adjustable electric cowl flaps to replace the original dual manual flaps. There was a vernier throttle control, more elbow room and new-look radiused windows.

The 231’s original 60-amp, 14-volt electrical system was upgraded to a 70-amp, 28-volt system. This was much needed, since a fully loaded K model could max out the electrics long before the days of moving maps. An electrically driven backup vacuum pump was made standard equipment.

The 252 also got further aerodynamic tweaking in the form of gear doors that fully enclose the wheels when retracted and cover the wells when the gear is extended. The 252 also got an increase in gear-extension speed to 140 knots, up from 132 knots. Maximum speed with gear extended is 165 knots for the 252.

In all, 889 231s were produced between its introduction in 1979 and 1985. The 252, introduced in the middle of the GA slump of the 1980s, is less numerous. Production totaled, ironically, 231 airplanes.The K model made a brief resurgence in 1997 as the Encore,when Mooney was going through yet another of its many reorganizations. But it was not to be and the model was dropped again in 1998.Meanwhile, the so-called long-body models, specifically the M20M TLS and later the M20R Ovation and Acclaim, eventually came to dominate the Mooney line.

PERFORMANCE

The K model lives in a league of its own when measured against the narrow market segment of four-place, turbo retractables. At cruise, the 231 outstrips its competitors—the turbo Arrow, the 182 RG and Commander TC—by roughly 20 knots, despite the fact that the 231 MPH (196 knots) top speed isn’t reachable under real-world conditions and probably at all.

Realistic max cruise is about 190 knots for the 231, but 170 to 175 knots is more like it. The 252 is about 10 knots faster, thanks to intercooling. Both M20Ks win the altitude battle as well, with a maximum operating altitude of 24,000 feet for the 231 and 28,000 feet for the 252, versus 20,000 feet for the Cessna and Piper. The Mooneys outclimb the others by about 150 FPM.

Due to physiological considerations, however, high teens to low 20s are the airplane’s best envelope. At lower altitudes, turbocharged airplanes aren’t much faster than their normally aspirated siblings. In fact, the 231 is actually slower than the 201 below 8000 feet, due to cooling drag. The J model will also outclimb the K model below 8000 feet.

Many owners operate 252s conservatively. One owner told us that 65 percent power yields 170 knots at 10,000 feet and 200 knots at FL210, burning 11.5 GPH. The 231’s numbers are proportionately lower at high altitudes, although the difference lessens the lower one goes.

With 75.6 gallons of usable fuel, the 252 can climb to FL280 and operate a total of 4.9 hours, or just under 990 nautical miles still-air range with reserves. The 231 has comparable range and endurance, but can’t fly as high.

231 VERSUS 252

The improved powerplant installation makes for a significant operational difference between the 231 and 252. The engine still produces 210 HP, but it does so at a markedly lower manifold pressure: 36 inches for the 252 versus 40 inches for the 231, thanks to the improvements in the tuned induction, cooling and turbo systems.

The 252’s induction and cooling air intakes are separate from one another. Induction air enters through a NACA scoop on the side of the cowling, is turned 90 degrees to minimize induction icing through inertial separation and passes through a larger, less-restrictive air filter. It’s then compressed and run through a 42-square-inch intercooler.

The result is dramatically lower temperatures for the induction air, from 60 degrees F at lower altitudes to 120 degrees F up high. That means more power at higher altitudes and a wider detonation margin. The 231’s critical altitude is only 14,000 feet, while the 252’s critical altitude is 24,000 feet. In practical terms, this means that the 252 can continue to climb at about 1000 FPM into the mid-20s, can fly higher and is faster once up there.

The most important difference between the 231 and 252 lies in engine management. The revised powerplant installation in the 252 made an enormous difference and makes the 252 a more desirable airplane. Because the 231 has a fixed wastegate, the pilot must constantly monitor manifold pressure and fiddle with the throttle to keep it within limits. Bootstrapping and overboosting are constant worries. Thanks to its automatic wastegate, the 252 doesn’t suffer these foibles.

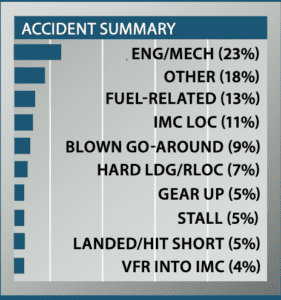

As we completed our review of the 100 most recent Mooney M20K series accidents we were pleased to observe a low rate of landing accidents. In fact, we combined hard landing events with runway loss of control (RLOC) crunches and still only had a total of seven. In our opinion, that’s a tribute to the handling of the aircraft during flare and rollout. We did note, however, that five pilots landed their M20Ks short of the runway or hit something on approach, two of which after going we’ll below the MDA on an instrument approach.

The big number was engine stoppage events—23—although that’s about par for all airplanes we review. Not surprisingly with legacy airplanes, where the cause of the silence up front was determined, it was improper maintenance—often failing to follow the manufacturer’s instructions when assembling engine halves or improperly torquing cylinders.

We felt that the number of fuel-related accident—13—was high. Pilots ran tanks dry and didn’t follow published restart procedures. Two pilots mispositioned the fuel selector and two detected water in the fuel but didn’t act aggressively enough to remove it.

To our amazement, 11 pilots lost control while flying in IMC, on an instrument clearance—that’s enough to be concerning and may reflect on aircraft handling. One lost control after the HSI failed—that should not be a big deal. In recovering from a diving spiral he overstressed the airframe.

Five pilots landed gear up—about average for retracts. One pilot selected gear down, heard it start to extend but didn’t confirm it had finished the task. The circuit breaker popped while it was in transit. The landing did not go quite as the pilot intended.

Another pilot got a radio call that his gear was up as he descended through 20 feet AGL. He hit the gear switch, applied full power and pulled up. Unfortunately, he stalled the airplane. It hit on the nosegear—that had just locked into position—broke it off and slid off of the runway and into a sign.

We were interested in one gear-up landing that was due—as are so many—to pilot distraction. Here, however, the pilot had deployed the speedbrakes so he was carrying enough power during the approach that the throttle position never triggered the gear warning.

We saw a disquieting number of accidents that could be put at the feet of bull-headed owners—hopefully not a symptom of M20K ownership. Two were especially notable:

Needing a GPU start because the battery was dead, the owner of a 14-volt system M20K didn’t flinch when the line crew told him the GPU was 28 volts and said things would be fine.

Upon switching on the juice, there was an explosion, and then a fire that consumed the airplane.

An owner who landed gear up provided a prop to the local mechanic so that the owner could ferry the airplane for the needed repairs and engine teardown. After having difficulty installing it, the technician discovered that it was the wrong prop. He refused to sign a ferry permit. After an argument, the owner took the airplane and launched. Not long after takeoff, the prop departed the airframe.

HANDLING

The 231/252 series handle like typical Mooneys: relatively heavy in roll and pitch, with good stability. The K models have greater pitch authority, thanks to a slightly larger elevator, and the longer engine makes it somewhat nose heavy. That can make flaring a challenge with a forward CG, but nothing like, say, a Cessna 182.

Pitch change with gear extension/retraction is slight, but flap extension produces a nose-down moment. Transition from full flaps to trimmed for go-around takes heavy pressure on the yoke and fast action on the trim. Using the electric trim, anticipation of configuration changes helps reduce pilot effort.

Speed control is essential when approaching and landing any Mooney. Approach too fast and the K model will float. Try to plant it on the ground and it will fight back, porpoising vigorously and striking the prop if uncorrected. This is a common accident for all Mooneys, not just the K model.

Because of its ability to fly fast, some owners say the best addition ever devised for Mooneys is speedbrakes. These are especially useful for the 231, which doesn’t have the 252’s higher gear limits. (Speedbrakes are standard on 252s.)

Ground handling isn’t great. The airplane is low slung and the Mooney’s stretched-out seating position hinders visibility on the ground. It also makes gaining purchase on the brakes difficult. The wingspan (36 feet, 1 inch), combined with the wide turning radius of 41 feet, makes negotiating a crowded ramp challenging. One other caution: Many Mooneys suffer damage to the nosegear trunnion when towing turn limits are exceeded via power towing. Owners learn to watch the ramp rats carefully.

CABIN, PAYLOAD

On paper, the 231 and 252 have the same loading characteristics. In reality, however, the typical 252 weighs more, simply because it has more equipment. Neither airplane is a stellar load-hauler. Gross weight is 2900 pounds and basic empty weight is 1800 pounds, usually more. Real-world, full-fuel payloads are on the order of 400 to 500 pounds, making the M20K a useful two-place airplane, with generous baggage. Thanks to its fuel efficiency and good endurance, however, there’s flexibility built into the load-carrying equation.

The latest M20K, the Encore, has about 200 pounds of additional load, thanks to beefed-up landing gear. Staying within the CG is easy and there’s no worry of aft-tending CG as fuel is burned off.

The baggage compartment is large, with a capacity of 120 pounds, although the high sill door makes it difficult to wrestle large objects into the airplane. Baggage capacity can be increased by folding the rear seatbacks down together or individually.

Mooneys are fast and efficient because they have low-drag airframes with a small frontal area. That translates into cramped quarters. The seating position is quite different from that of most airplanes. It’s more of a sports-car posture than an upright seating regime. There’s plenty of legroom fore and aft, but less lateral room. Those of below-average height may find that they can’t reach the rudder pedals without a booster cushion behind their backs or pedal extensions.

Early Mooneys tended to be spartan in interior arrangements. But by the time the 231/252 appeared, Mooney recognized the need for more modern if not luxurious appointments. Thanks to a bit more elbow room and somewhat plusher finish, the 252 is arguably more comfortable than the 231. The 252 is also quieter and many feel it’s the quietest of all Mooneys, thanks in part to the induction system and the fact that things quiet down the higher you fly.

The panel layout is quite good, with one seemingly obvious feature that has probably averted many incidents: The gear selector is located high in the middle of the panel so it’s hard to miss. The flap switch is located low on the center console, along with the trim/flap indicators and, in the 252, cowl flap controls. The power gauges are on the far right and angled toward the pilot. Engine gauges are well-placed, right under the glareshield in front of the pilot. The panel also has a good selection of annunciator lights at the top of the radio stack.

MAINTAINING IT

From an airframe standpoint, Mooneys are relatively trouble-free. Long-standing caveats include the potential for corrosion of the cabin frame tubes—particularly if the windows develop leaks—and the typical fuel tank leaks that plague all Mooneys. Keep it hangared—and covered when outside—to keep the trouble to a minimum. But the systems in general are simple and robust. The steel gear legs gear have no oleo struts, relying instead on rubber donuts for shock absorption. These need to be replaced periodically. There’s no complex electrohydraulic system driving the gear as is found on Cessnas—Mooneys are electromechanical. The flaps, too, are electric; both are relatively trouble-free.

The powerplant, however, is another matter. Difficulties fall into several categories: magnetos, con rods, cylinders and turbos. Most airplanes have been retrofitted with pressurized mags but check any used model to be sure. The same applies to connecting rods. The suspect rods are Continental part number 626119 and have a C logo with a circle around it. Only a barn dweller would still have the old ones.

Many turbocharged models encounter mid-run cylinder problems of some sort and the K model is no different. These include the full litany: worn valves and guides, broken rings and cracked jugs. Midtime turbo and magneto replacements aren’t uncommon, but they aren’t a sure bet, either. The 231’s fixed wastegate means the turbo is working constantly and the engine is susceptible to overboosting.

The 252 doesn’t suffer these problems, although it had trouble with cracked tubes in the induction system before Continental came up with flexible tubing. Even though the 252’s engine installation is less troublesome than the 231’s, temperatures and stresses on turbocharged engines are greater than on normally aspirated engines. Regular inspections and proactive maintenance are a must for reliable dispatch rates.

CURRENT MARKET

Like most other piston singles, the used Mooney market has seen a sharp rise in values, with well-cared-for and upgraded models fetching a sizable price increase. For starters, the Fall 2022 Aircraft Bluebook says a 1979 M20K 231 has an average retail price of $130,000, but we think that’s a lot lower than typical asking prices. We found a 1979 231 on Controller.com listed at $210,000, with 800 hours on an overhauled engine and over 3000 hours on the airframe. It’s we’ll equipped with speedbrakes, Garmin avionics long-range fuel tanks and updated interior.

A 1987 252 TSE, according to Aircraft Bluebook, typically retails for $190,000, and clean ones with low-time engine, avionics, paint and interior upgrades might sell for closer to $250,000 or more.

AVIONICS AND MODS

The 231/252 is worthy of modern avionics and a market scan shows some owners go to town with major upgrades—we’re talking packages that near $100,000 including all-in-one digital engine monitors and new panel fabrication. Others make do with original King Silver Crown radios, but we don’t think this is a long-term solution.

Garmin’s GFC 500 autopilot has an STC for the M20K and it flies the airplane like it’s on rails, plus there’s also the G3X Touch integrated avionics. If you’re considering a 231/252 and don’t plan to upgrade the autopilot, pay close attention to the performance of the existing system, which is likely the King KFC150. Earlier servos are extinct and flat-rate repair for the system components is hefty. S-TEC has a multitude of STC approvals for the M20K and you might find one with an S-TEC 55 series. Again, pay attention to the performance during the prebuy.

There are fewer speed mods for the K model than for earlier Mooney types, such as the C, F and J models. Single-piece belly skins, minor speed mods, rudder and elevator hinge covers and oversized bushing kits for the nosegear are available from Lake Aero Style and Repair (www.lasar.com, 707-263-0412). The company, an FAA repair station, also advertises that it does ADS-B retrofits for Mooney models.

Whelan (www.flywat.com) has an HID landing light for the K model and hubcaps with filler valve access holes, while Precise Flight (www.preciseflight.com) has speedbrakes and the Pulselite system.

A big-dollar mod, the Rocket conversion replaces the TSIO-360 with a 305-HP Continental TSIO-520-NB, yielding 220-knot-plus cruise speeds. Although the conversion is discontinued, these turn up on the used market and you’ll pay a premium for it.

Perhaps the most desirable mod for a 231 that makes it more like a 252 is an intercooler. One system—the Turboplus—has been highly recommended by M20K owners and it comes from Turboplus Aircraft Systems (www.turboplus.com) in Gig Harbor, Washington.

Turboplus says it was the first company to bring intercooling for GA singles and twins in the early 1980s and there are thousands of Turboplus intercoolers and induction systems in use today.

The company says its M20K intercooler kit can yield a max speed of 241 MPH at 24,000 feet, and 170 knots true airspeed at 10,000 feet and 65 percent power, with the added benefit of lower cylinder head temperatures. The STC’d kit for the Mooney M20K is $5995 and the estimated installation labor is around 18 hours.

“My conclusion is that the Turboplus intercooler provides much improved intake manifold cooling and an increase of 3 inches in available manifold pressure at altitudes above the 13,500-foot critical altitude, while providing significant performance benefits across the board to the hot-running, non-intercooled engine in the 231 M20K,” reader Geoff Lee said of the system.

CHECK INSURANCE, UPKEEP

Senior (and inexperienced) pilots should get an insurance quote before making any deals on these airplanes. Retracs and high-performance models have been red flags in the insurance world and the 231/252 fits the profile. Moreover, plan on finding quality transition training from an instructor who knows the airplane well. A good place to start is the Mooney Aircraft Pilots Association, or MAPA, at www.mooneypilots.org. We think MAPA is a must-join for anyone serious about buying and owning any Mooney. There’s also www.mooneyspace.com, plus the 9600-member private Mooney Pilots group on Facebook.

When it comes to maintenance, bring the 231/252 to a shop that has experience with the model. While not overly complex, not all mechanics are versed with Mooney systems, and you’ll want a mechanic who knows what they’re looking at.

Last, before buying any Mooney, look carefully at the maintenance records and arrange for an expert inspection by a mechanic who doesn’t have a stake in the deal.