As we reported in the August 2015 issue of Aviation Consumer, the maturing support network for LSA models is building at least some confidence in their dispatch reliability. But for owners and flight schools looking for a simple and reliable trainer that’s easily supported on most every maintenance floor, it’s still tough to beat the familiar Cessna 150/152 series.

That’s why old 150s are still flying side-by-side on the rental line with ultra-modern light sport designs and the older airplanes, despite decades of abuse, still hold up better than some newer LSA models and often require less maintenance. The harsh lesson here is that despite advances in materials and computer-aided design, the 1950s engineers who designed the 150 knew their way around structure and half a century later, what they built still remains serviceable for the foreseeable future. The airplane that trained thousands of pilots (us included) endures.

Model History

Cessna was a latecomer to the post-war pilot boom. With its iconic yellow Cub, Piper owned the market during the 1940s, but that was all to change when Cessna created the 120 and later the 140, which stayed in the model line until the early 1950s. Although only hardcore Cessna aficionados know it, the Cessna 172 actually predates the Cessna 150, which first appeared in 1959.

Unlike the 140, the 150 was created solely with the training market in mind to tap into what was then a booming market. Would-be buyers had disposable income, the economy was strong and the post-war flying frenzy was still a real trend. The world needed a practical, cheap and no-frills trainer that wasn’t made of cloth.

Ever practical, Cessna provided. By modern standards, the first 150s look a bit frumpy, with their squared-off tails and a turtledeck-style fuselage, with no rear window.

But it was not to stay that way for long. In 1961, the first of many changes in the model began, starting with moving the gear struts aft two inches, curing the airplane’s tail heaviness. Ten years later, tubular gear legs with a wider track were added.

In 1964, the rear window appeared and, of course, it needed a snappy marketing moniker, thus was born “Omni Vision.” The stodgy straight tail went away in 1964, replaced by the swept-back tail, giving the airplane a more rakish look.

The overall dimensions of the airplane haven’t changed much, but its max gross weight has. The 150 began life as a 1500-pound airplane, but by 1978, the gross weight had been bumped up to 1670 pounds for the 152. For a two-place airplane, that’s a big hike but, as is usually the case, there wasn’t much payload gain due to rising empty weight.

Anyone who learned to fly in a 150 will remember the cockpit as cramped and narrow and that never changed. But Cessna did bow the doors out slightly and trimmed the center console to provide more legroom.

The baggage compartment was also enlarged several times and one option included a rear child seat. The baggage area could accommodate up to 120 pounds of kids and/or bags, so it was suitable for a toddler and a day bag, but little else. But for a small airplane, the baggage area is rather generous and easily accessible for an instructor fishing for a chart or a hood.

In 1975, a larger fin and rudder were added and before that, electric flaps were installed. Previously, the flaps had been manually operated and some pilots complained that electrics were a step backward. We agree.

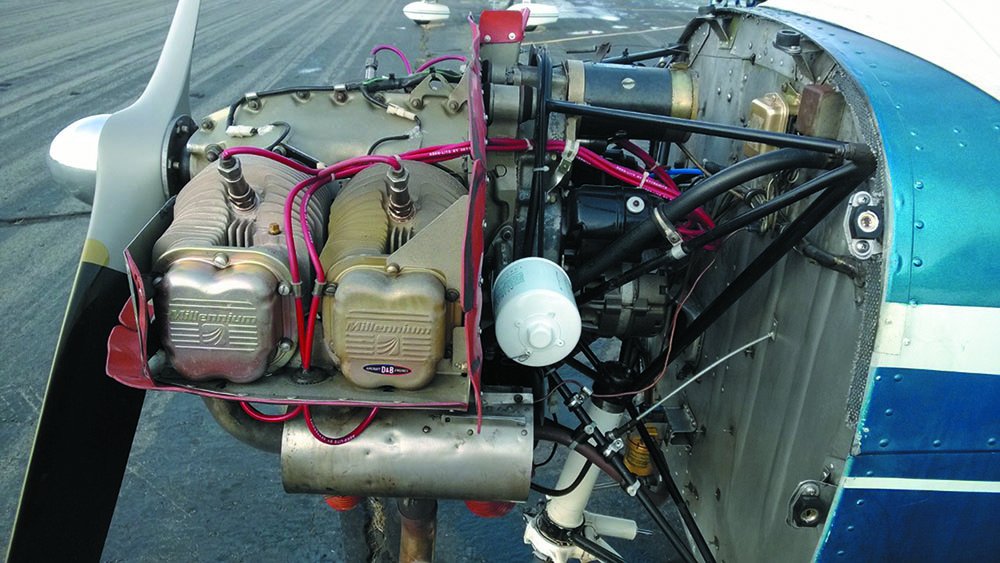

Engine Changes

The Cessna 150 first appeared with a 100-HP Continental O-200, a reliable and easy-to-maintain engine that matched the airframe nicely. When 80/87 gas began to fade from the market in 1978, displaced by 100LL, Cessna switched to the 110-HP Lycoming O-235 that provided more power and boosted the TBO from 1800 hours to 2000 hours and eventually 2400 hours.

As the 150 morphed into the 152, there were other changes, including a 28-volt electrical system, a one-piece cowling, a McCauley gull-wing prop, an oil cooler and redesigned fuel tanks. Sum total of changes? About 40 pounds more useful load than the original Cessna 150 had, but fully 60 pounds less than a 1948 Cessna 140 could heft. The airplane’s performance was about equal to the 150 it replaced, but the engine was susceptible to severe lead fouling when burning 100LL and the 28-volt electrical system was a nuisance.

Also, the 152 turned out to have some significant warts. Early models were hard to start because of weak spark and lack of a priming plunger. Cessna added impulse coupling on both magnetos to improve this, plus direct priming for each cylinder. Mechanics complained about having to remove the prop to decowl the engine so Cessna added a split cowl. In 1981, the Lyc got a spin-on oil filter as standard, rather than the old rock screen. In 1983, Cessna and Lycoming tackled the lead fouling issue by replacing the O-235-L2C engine with the N2C variant, which the model had until it was discontinued in 1985.

Except for troublesome starter drives, the Continental O-200 used in the Cessna 150 was a reliable and robust engine that could be counted to make the 1800-hour TBO, if not beyond. The Lycoming O-235L2C was supposed to achieve three goals: Solve the O-200’s lead problem, boost power a bit to increase the payload and offset the 15 percent gain in empty weight and last, reduce noise. The higher compression O-235 Lyc delivered its 110 HP at 2550 RPM rather than the O-200’s 2750 RPM.

Did Cessna hit the mark? Not really, say operators familiar with both airplanes. In its favor, the Lyc had no starter problems, but if the engine/prop was quieter, you’d hardly notice. Owners complained about high parts prices for the O-235—including pistons and valves, the latter being sodium filled for improved cooling.

And the lead problem? Still there, say owners. The O-235 accumulated lead deposits in every nook and cranny and lead fouling of plugs became such a problem that Champion developed a special extended-electrode spark plug for this engine, the REM37BY. Mechanics say even with careful leaning, the plugs must be removed and cleaned as often as every 25 hours. In Service Instruction 1418, Lycoming explains a procedure whereby cylinders can be blast-cleaned with walnut shells without removal for top-end overhaul. Prior to this, operators found that early tops were needed due to lead fouling.

One positive aspect of the Lycoming engine is its TBO—a whopping 2400 hours. If you can keep the thing from choking with lead, it may actually reach that impressive limit. Some owners use TCP additive to help control lead. Also, thanks to intense competition in the engine overhaul field, overhaul prices remain affordable, on the order of $15,000 to $20,000.

Unique to the mass-market trainer, Cessna offered two additional versions of both the 150 and 152—the Aerobat and a seaplane conversion, which appeared in 1968. There are still a few of these models running around, some even used on the water. The seaplane was, by most accounts, a decent little water taxi, although no one would mistake it for a Beaver. It couldn’t haul much and with limited power, it took a while to unstick from the water.

The Aerobat version—which first appeared in the 150 in 1970—made a much bigger splash, although not in the water. In those days, aerobatic training was all but impossible so when the Cessna Aerobats, with their flashy checkerboard paint, showed up on the rental line, many renters responded enthusiastically. Some 5 percent of the 150/152 fleet is acrobatically capable, after a fashion.

We’re not talking Extra 300 or even Pitts-type performance, of course. Aerobatic purists sniff at the Aerobat because it has control wheels, not a stick. Any maneuvers that require climbing back to altitude will require a plodding climb to get back in the perch. Still, the Aerobat was and is an affordable gateway into the world of aerobatics and at the very least, upset training. The Aerobat commanded a price premium when new—about $1500 to $2000—but on the used market, the Aerobats bring as much as $10,000 or more, or nearly 50 percent higher average retail.

Performance, Handling

The trainer market has evolved considerably since the 150 first appeared and although modern trainers such as the Diamond DA20 and a passel of LSA designs have improved the breed, technologically, at least, the 150/152 still has better than credible performance and handling traits. Interestingly, some flight schools report that although many students take intro rides in a sexy LSA with a glass panel, they transition to a 152 or 172.

Why? Probably because the 152’s higher weight gives it a somewhat stabler feel than a hyper light LSA and pricewise, 152s remain competitive to buy and operate, so the hourly rental is less. Furthermore, some instructors say it’s easier to solo a student in a 150/152 because LSAs tend to be twitchy, especially in pitch.

But the Katana cruises faster than the 152 and uses more fuel. It’s a better climber than the Katana A1, with its 80-HP Rotax engine, but the C1 Katana, with its Continental IO-240, outdoes both the 152 and the A1 Katana, not to mention many LSAs.

Top speed for the 152 is given as 109 knots, same as the Tomahawk and two knots faster than the plodding Skipper. In the real world, owners say they go slower. Much slower. The airplane seems happiest at 90 to 95 knots, a realistic speed in our view.

Handling is what it is, which is predictable, with relatively light control forces and no nasty stall habits. The Cessna 150/152’s slow flight characteristics are so utterly benign that they nearly qualify as STOL airplanes. The large flaps—even when limited to 30 degrees—are quite effective, although they do generate quite a nose-down trim moment. This is easily handled, although the control forces escalate somewhat. Students have to be taught to watch for abrupt noseups when applying full power for a go-around, training that prepares them nicely to transition into the Cessna 172, which has the same characteristic.

Landing a 150/152 is easy enough to teach and learn, to a point. And that point is often exceeded, since runway fender benders are the most common type of accident suffered by the 150/152 series and other trainers, for that matter. The model is an excellent crosswind trainer, since it has an effective rudder.

The airplane is comfortable with an approach speed of 60 knots or slower, but it will easily tolerate higher speeds, because those draggy flaps bleed off excess airspeed in a heartbeat. Land it fast and it will bounce. (Any pre-buy should include a specific check of the logs for landing damage that included nosewheel work or firewall damage.)

Operators tell us the 152’s runway performance is good, especially if the airplane is light. It’s not as good when heavy on a hot day. With a portly CFI and student aboard, more than a few 152s have trimmed the trees off the end of runways.

Speaking of payload, the 150/152 essentially carries what other popular trainers do. At 528 pounds useful, it carries a bit more than the Katana but a bit less than the Skipper and Tomahawk. Before the model got fat, some E/F/G 150s topped 600 pounds in load-carrying capability.

Where the 152 shines, however, is on load flexibility. With a fuel capacity of 39 gallons for the long-range tanks, it has better range with a single pilot than either the Tomahawk or the Skipper. Does this really matter? Maybe. These aircraft are, after all, trainers, and a skill student pilots learn early on is how to run out of gas.

Cabin, Ergonomics

Cabin comfort is not much of a consideration in two-place trainers. Lessons are short and there’s no point in pretending there’s enough room in the airplane for plush seats. The 150/152 is so narrow that even pilots of moderate size will bump shoulders. Two big guys will be miserable. Although the seat height is quite low, the legroom is excellent.

In 1979, thicker seat padding became standard, but it helps only a little. Many owners have had the seats repadded or carry a pillow or two to make them more tolerable. Noise level is quite high, due to the proximity of the cabin to the engine compartment, but the advent of noise-canceling headsets and intercoms has rendered this moot.

Ventilation in the 150/152 is via the standard Cessna pull vents in the wing roots, plus in most models the windows open for taxi and can also be opened in flight. During the winter, this can be a mixed blessing and some operators tape off the root vents to reduce drafts. If the heater is well-maintained, it will get the job done.

Maintenance

Owners who use the 150/152 for personal use—and many do—can count on literally years of service from the engine, if they’re operated enough to keep corrosion at bay and leaned to avoid lead buildup. In general, these are simple airframes that don’t require much maintenance. However, any that have been used extensively as trainers—as most have—should be inspected carefully for hard landing damage, especially in the nosegear/firewall bulkhead area. Wrote owner Ed Park of Aliso Viejo, California, “Unless the guy that you bought the airplane from spent a bunch of time and money fixing up that 20-year-old airplane and fixing/replacing/repairing a lot of things, you can expect that you will be that person if you are conscientious about your maintenance.”

The 150/152 series has what we would call an average list of ADs, none of which are particularly onerous or expensive. The major safety-related item is the seat track AD, which prevents the seat from unlocking and sliding rearward. Most aircraft should have had this done long ago.

Owners report that annuals are thrifty—in the $800 to $1200 range, depending on parts needed.

Mods, Owner Groups

The 150 can be given a power boost and even turned into a taildragger, as quite a few have been. The only current 150 taildragger conversion we could find is through Lowe Aviation, at taildraggerconversion.com, 270-929-3776. The STC applies to 1959-1963 Cessna 150s. These are the straight back/straight tail 150s that were manufactured using tooling and parts from Cessna 140A fuselages. This conversion uses Cessna 120/140/140A main gear and tailwheel gear. We couldn’t verify the existence of other conversions (Texas Taildragger or Bush) that use the original Cessna 150/152 landing gear moved forward on the fuselage.

Horton, Inc. (www.Hortonstolaircraft.com, 800-835-2051) sells STOL kits for the 150/152. Met-Co-Aire sells wingtips for the 150 series, reach them at 714-870-4610 or www.metcoaire.com. O&N sells aux fuel tanks for the 150/152. Visit www.onaircraft.com or 570-945-3769.

Air Mods N.W., sells an engine conversion for 152s that includes a new prop that boosts climb and takeoff performance by allowing the Lycoming O-235 to spin up to 2800 RPM. It also has a higher compression ratio so supposedly, this decreases lead fouling. See www.airmodsnw.com.

Two organizations of note are the Cessna Pilots Association and the Cessna 150-152 Club. CPA’s Santa Maria, California, HQ is the fount of all things Cessna and members rave about its technical services. Visit CPA at www.cessna.org.

The Cessna 150-152 Club has a monthly newsletter that’s an excellent clearing house for information, parts, mods, maintenance and service tips. Contact the club at 541-772-8601 or www.cessna150-152club.com. For a detailed book on flying and operating Cessna 150s, contact Arman Publishing at www.Cessna150book.com.

Owner Feedback

We have owned our 1968 Cessna 150H for over nine years now. We like the 150 because it is relatively inexpensive to own and operate—perhaps one of the least expensive airplanes a person can own. Insurance this year was about $450 and the annual inspection was $710, which included replacing a few things.

Its fuel burn is less than 6 GPH, but we still flight plan for a solid 6 GPH. The airplane is all metal, so it can be tied down outdoors instead of renting a hangar, although it is important to have a canopy cover and a good coat of wax to protect the paint. You can buy a good Cessna 150 for the price of a good used car.

In my opinion, the number one reason to own one is because it’s so fun to fly. Control response—although not like a Pitts—is light and responsive. With 40 degrees of flaps, it will descend like a helicopter.

If you need to go somewhere, these are not the fastest airplanes, but still beats driving by about half on most trips. As many Cessna 150 owners have demonstrated (and demonstrate every year at the Cessna 150/152 Fly-in in Clinton, Indiana), these airplanes can be reliable, long-distance transportation. Many people I know fly IFR in their 150s on a regular basis.

Pilots are mission-oriented individuals, and one of the first pieces of advice a prospective owner receives is to define their mission, then start looking at airplanes that will fulfill that mission. If your mission is to have fun flying on a budget, a Cessna 150/152 can hardly be beat.

Stacey Morris

via email

I purchased a 1973 A150L to teach my daughters to fly, versus paying for lessons at the FBO. No one wanted to rent me an airplane to instruct in. At 155 pounds and five feet, eight inches tall, I’m the giant of the family. We just fit in a 150 well. The plane will be used for training and taking friends for short joy rides.

It is IFR certified with a Garmin GNS430W, so I can’t do most of the commercial and instrument work with this 150. I just renewed my insurance policy with Old Republic Insurance. The premium is $627 for $35,000 in hull coverage and $1,000,000 liability. This also includes the insurance cost to instruct my two teenage daughters. Try getting those rates with a two-seat car!

Only 734 150 Aerobats were built out of 22,000-plus 150s, and only 264 150 Aerobats are still registered in the United States. A great trainer should be easy to fly, but a challenge to fly really well. It should be capable of mild aerobatics for unusual attitude training. I’ve seen high-time, skilled pilots botch unusual attitude recovery because they’ve never been upside down. Some ground instruction and 1.5 hours of unusual attitude training in an aerobatic aircraft can make them better pilots than I am. Since I don’t want my own daughters to botch an actual unusual attitude, the A150 is just the ticket for instruction. Plus, it’s just so much fun to fly for a miserly 5 GPH fuel burn.

Tim Boese

via email

I’ve owned my 1978 Cessna 152 for almost six years now. I live in upstate New York and have family and friends spread out over the Northeast. With many holidays and vacations spent stuck in traffic for hours, flying to destinations seemed like a great idea and much more fun. Renting airplanes for long weekends was problematic, so I looked into ownership. Since I don’t have kids, a two-seater could fit most of my missions while keeping costs at a minimum—perhaps as minimum as flying gets. The 150/152 seemed like a good choice, as I was familiar with it from flight training, plus with so many produced over the years, parts and model-experienced mechanics are relatively easy to find.

My mid-time 152 came with the Sparrowhawk modification, a propeller change and different pistons that ups the horsepower from roughly 110 HP to 125 HP. I’m not sure if this does much to improve the cruise speed because it’s still nowhere near book numbers, but the climb rate and fuel economy I see are better than book, so it may be a worthwhile mod to consider. The prop upgrade also eliminates the AD.

The avionics in the plane were dated, although there was a Loran installed that I appreciated for a few months before the Loran network was shut down. I eventually replaced the Loran and aging ADF with used avionics, including a Garmin GPS-155XL and a glideslope system. This provides good IFR capability, including GPS approaches. I also had Knots 2U flap gap seals installed. This improved handling near the stall speed and contributed modestly to the improved climb rate.

As currently configured, full fuel (24.5 gallons usable) gives a maximum ramp weight of about 360 pounds, which works out OK for myself, my girlfriend and some luggage. The 152 offers a little more shoulder room than the 150, but the cabin is still a very cozy place to be. I am six feet tall and fit we’ll in the plane top to bottom, however I’ve found the seats can be fatiguing on longer flights. Still, I can fit my full-size road bicycle in the cargo area (with both wheels detached) if I happen to be flying somewhere solo, although admittedly I have to figure out how to get the frame through the door every time I do it. I plan trips at 95 knots and 6 GPH, but do a little better than that overall (it’s closer to 100 knots true and 5.5 GPH).

Insurance costs have been $400-$600 per year. Annuals have averaged about $2500, with a high year of $5700 and a couple of low years a little above $1000. Spark plug fouling had been an issue from early on, so I now lean religiously everywhere except for approach and takeoff. This has helped to mitigate the problem, but it still exists to some extent. The time between plug cleaning has lengthened so I can just have it done at the annuals.

I’ll sum up the flying experience with a few words: Simple, slow, forgiving, fun, economic. With a standard-day liftoff in we’ll under 1000 feet, and initial climbs of 800-900 FPM, getting out of most airports isn’t a problem.

My 152 has also been a fine IFR aircraft. While I believe many people would be put off by its lack of autopilot and its light wing loading, it has been a good plane to enhance and practice instrument skills. Moderate turbulence can make approaches more challenging to fly precisely, so I’ll typically up my minimums in that situation. Headwinds can be a big weather nemesis. With such a low cruise speed, a 30-40 knot headwind can make some trips a lesson in patience—or downright impractical.

The 152 has been a good fit for my flying mission. Of course, I’d like to have more capacity and speed, but for the cost, all things considered, its total utility has been hard to beat.

Tom Gibney

Ballston Spa, New York

I bought an IFR-capable 1970 150K the week before the checkride for my private pilot certificate and have flown it for four years and 900 hours as a time builder and runabout, although the plan was to do IFR training. I can fly plenty of VFR and although I practice a lot of IFR procedures, I never got around to completing the rating.

With a little luck and a tailwind, students can go the qualifying distance for the commercial cross-country flight requirement, but it’s that 250-mile leg with a decent fuel reserve that can take a bit of doing.

I’ve flown some long cross-country flight in my 150—1890 nautical miles over 24 hours being the most recent. Just think of it as a series of 2.5 hour legs, with two-hour legs and a bigger fuel reserve at night. For day VFR fuel minimums, consider one-hour reserve and not the FAA rules. Accidentally running the engine full rich (with a relatively small fuel supply to begin with) you might embarrass yourself.

As for budget, with an engine replacement fund, insurance, tiedown costs in New England and 250 hours per year operation, my operating cost is $68 per hour. I perform all Part 43 owner-allowed maintenance to meet that cost, while allowing a discretionary $1000 a year for upgrades.

Insurance for me flying 250 hours per year, phased in the FAA Wings program and completing a flight review every year (because I choose to) runs $402 per year (through EAA), with a $25,000 hull coverage.

At 5000 hours on the airframe and a life as a trainer, stuff is wearing out. My mindset is to not screw around with salvage parts if new parts are available reasonably. I’ve found that McFarlane Aviation offers most of the important stuff at reasonable prices. I suggest that a potential buyer should boroscope the aging airframe as part of the inspection. Even a show-winner can have corrosion.

When you know it’s corrosion free, ACF or Corrosion-X it and get some peace of mind for the future, especially when basing near the coast. Anytime you have the airframe opened up, renew the treatment.

See those little pairs of holes along the belly? They are there to drain water from the hull. Clean the mud from around them and every time you wash her off, poke some safety wire in the holes to make sure they are still clear.

There is a lubrication schedule in the service manual, mostly based around 50-hour intervals. Spend the effort getting at all those sheaves and bellcranks in the tailcone, hull and wings clean and lubed. While sealed for life (40 years ago), you will enjoy a lighter control feel.

Consider fitting the spin kit (and lose the AD-limiting placard) and get some quality spin training, plus install shoulder harnesses. The attachment nut plates are almost certainly in place since it was a factory option. An hour’s work could save you smashing your face on the yoke and could save your life.

I think the 150/152 is just big enough to be a proper airplane for flying in the national airspace system. This is not to say a Cub, for example, is not, but a long cross-country flight in a Cub will likely require a lot of sitting out. A 150 can be flown IFR with care and make real trips, but I suggest spending some money to reupholster the seats with modern materials. Your back will thank you.

Graeme J.W. Smith

via email