by Larry Anglisano

While glass cockpits seem about to render the common iron gyro a barbaric antiquity, most of us still fly behind a combination of vacuum and electric attitude, directional and rate gyros. Like any mechanical device, they wear out and fail, inviting disaster if the failure occurs in IMC.

When a gyro rolls over and dies, what do you do? Should you shotgun the entire instrument for a new one? Fix whats wrong? Pay for a complete overhaul? And which shop do you pick to do the work? In this article, we’ll attempt to sort through the fog of gyro repair decision-making.

In general, if an expensive gyro has to be sent to a specialty shop for work, we tilt toward having it overhauled when the case is opened up. Most owners have been through the frustrating hassle of having a minor problem fixed…three times. By the third removal, an overhaul starts to look like a bargain option.

Finding a Shop

Trade-A-Plane is chock-a-block with ads for self-proclaimed instrument shops and advertised prices for overhaul of common instruments are all over the map. As we scouted the ads, we found a range of repair and overhaul pricing between shops small and large. Some offer serviceable exchanges, some tout repairs and some push overhauls for low fixed prices. We know of one small instrument shop who told a customer that it performs overhauls for a well-known major instrument shop that, in turn, claims it does all its own work. A single phone call uncovered the ruse.

We asked a couple of the major shops how some repair facilities can offer such low prices-sometimes lower than the parts and labor required for a proper overhaul-on even the most expensive gyros? We were told that not all overhauls are created equal. Digging through the regulations governing instrument overhaul procedures is the typical FAA paper chase; its not done equally we’ll by all shops and the procedures are open to interpretation.

A true gyro overhaul means a complete teardown and replacement of all internal components-from rotors and bearings to O-rings and gaskets-bringing the gyro to new standards. Perhaps the only component of the gyro that remains after this teardown and overhaul process is the case and glass and a first-rate shop will even restore the case with new paint. All outstanding mods are performed and a complete teardown report is issued for placement in the aircraft logbooks when the gyro is returned to service.

Warranties vary, too, and you want a good one. The standard warranty for a zero-time, overhauled gyro is normally one year, the same warranty placed on a new gyro. When you shell out $3000 for an overhaul, part of what youre paying for is a reliable warranty; the shop builds this into its pricing structure.

None of this is to suggest that you cant get good repair/overhaul work from a smaller shop. We think there are local shops that do excellent work but the ones that do price accordingly. Let your avionics shop or mechanic be your guide. If the shop has a long history of happy results from an instrument repair facility, take the recommendation at face value. No sensible mechanic will deal long-term with a bad shop; the grief wont be worth the savings.

Besides the warranty, we think an owner should look for two other things: documentation on what was found during the overhaul and what was replaced and a generous supply of on-the-shelf overhauled gyros for quick replacement and AOG service.

Larger shops will offer either an overhaul of your existing gyro or provide an overhaul exchange unit at the same price. Some have loaners on ready standby. If you use your airplane frequently, we think having this replacement flexibility is essential.

Overhaul, Exchange

When DGs start to precess and horizons get lazy, our confidence in their performance and reliability fades and so should yours. Given the importance of these instruments for IFR flight, we favor a pro-active maintenance stance. By zero-timing these instruments, you’ll increase your confidence when your eyeballs are fixed on their every twitch in low weather.

For the most part, basic attitude gyros and DGs are cheap enough that overhaul exchange is sensible as is a rebuild of your own instrument, if time permits. In most cases, the $500 to $600 price tag doesnt warrant the expense of removal and reinstallation just for a basic repair, especially if the gyro sees you through weather and is high time since its last overhaul or replacement. For basic gyros, our view is this: if the gyro needs to see an instrument shop for abnormal symptoms, have the shop overhaul it while its opened up so you wont have to deal with it two months later. Or simply replace it and move on.

Its not so simple for remote and self-contained gyros for compass systems, flight directors and HSIs, however, and maintenance gets pricey.Take the KG102A, a remote electric gyro for the Bendix/King KCS55A slaved compass system with HSI. The reliability and service history of this device is excellent but its a complex design and a trip to the instrument shop is usually costly.

Experience has proven that if this gyro hasnt seen an overhaul in many years-that could be a decade or more-a teardown and overhaul is again the best option. Some older vintages-serial numbers below 17700-arent updated with the latest mods and might not be serviceable at all without overhaul. On the other hand, the unit is easy to remove and weve seen many cases where a recently overhauled KG102A could be repaired at moderate cost, without resorting to another overhaul.

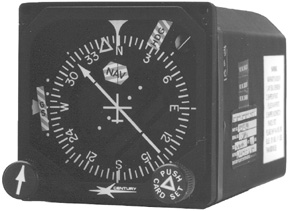

Thats what makes the Bendix/King system such an attractive option, from the maintenance point of view. The same cant be said of the Century NSD360A HSI, however. Owners should expect pricey maintenance intervals, repairing meter movements, gyro components and the instruments belt drives.

While the NSD360A is a good option for a low-cost HSI, its time between service interval compared to the Bendix/King KG102A is shorter. Dave Vorsas, at JDC Company in Fort Lauderdale, a major instrument repair house, told us that by the time the entirely self-contained NSD360 is opened up, youre there, you might as we’ll overhaul at that point.

The self-contained, all-electric Century NSD1000 HSI has proven to be an instrument repair shop dream-or nightmare, depending on your point of view-with a blemished service record. One Baron owner we know reports that his NSD1000 underwent three factory overhauls in an eight year span, as we’ll as two meter movement replacements and numerous repairs. Some Cirrus owners have ditched NSD1000s for other electric models, due to frequent gyro and meter failures.

For turn coordinators that don’t drive autopilots-and thats most of them-replacement or exchange is usually the best option. Some shops might suggest a cheap, short term fix for sluggish and lazy units by doing simple cleaning and adjustment. Thats okay for a quick fix but you should budget for eventual replacement.

Autopilot Gyros

Attitude-based autopilots offer smooth rides and precise course intercepts, thanks to the precision of the horizon gyro. But when the autopilot wont, the problem is often a faulty horizon gyro. This will require troubleshooting, as the gyro may appear to perform fine but its electric output-hidden from the pilots view-might be useless to the autopilot.

Gyro-related AP problems can be acute and unpredictable, such as wild roll and pitch oscillations or trim runaways that will scare the bejesus out of the most seasoned pilot.

We recall one Seneca owner whose Century III autopilot would try to roll the airplane on its back when roll mode was engaged. Troubleshooting on his own, the owner sent virtually every autopilot component to the factory for repair, with no success. In desperation, he had the Edo Aire 52D-series gyro tested and found that it was outputting a faulty signal reference to the autopilot, a common occurrence. Since the horizon looked okay, he dismissed the gyro as the culprit.

Autopilots that rely on a vacuum-driven horizon gyro include Century and Piper Autocontrol systems. Several manufacturers make gyros for these systems, including AIM, Edo Aire, Sigma-Tek and Century. As long as the cross reference part numbers are adhered to, exchanges, overhauls and repair of these gyros are readily available. Still, our comparison chart tells a tale of confusingly similar model-numbered gyros, depending on the autopilot, options and flavors. Some gyros have 3-inch ATI square bezels while some have standard 3-inch round mounting configuration. Some have lighting, some don’t. Some have short style cases and some have longer cases, depending on the application.

Most Bendix/King KFC and KAP systems use a horizon gyro for roll and pitch reference-the rate-based KAP series systems found in newer Cessna aircraft use the electric turn coordinator for reference. S-TEC autopilots rely on the rate gyro in the electric turn coordinator for roll reference. While this is a reliable and more cost effective source for driving an autopilot, some might argue that the ride isn’t as smooth as an attitude-based system. But in the event of a vacuum system failure, the S-TEC will keep the wings level where a vacuum-based attitude AP wont.

For new autopilot installation, a common directional gyro is the Sigma-Tek, 4000C series, which is available in variants available for the correct interface with S-TEC, Century and other common flight control systems. One Sigma-Tek model, the 4000HR, even has a fake heading bug, whose only purpose is marking a reference heading, a smart option.

R.C. Allen offers standard horizon and directional gyros that are a bit cheaper than the Sigma-Tek line. Both companies have provided gyros to aircraft manufacturers as standard equipment. The important point here is this: if your shop says your horizon gyro is kaput, review at least some of these equivalent replacement options before deciding on a fix. You could save yourself some money and have a better gyro to boot.

Removal, Reinstallation

Whether you go the repair, overhaul or exchange route, you’ll be faced with the cost and hassle of removal and reinstallation. In some airplanes, this is easier than in others. Removing gyros from an airplane that doesnt have a removable glare shield is not a techs idea of a good time; he may have to yank other instruments just to gain access. Most owners underestimate the time it takes to remove and reinstall instruments, not to mention the testing and return-to-service paperwork that the FAA makes more onerous every year.

We recall the recent replacement of a slaved NSD360A HSI in a Piper twin.The original was a basket case, long overdue for overhaul. Due to time constraints, the owner opted for an overhaul exchange instead of waiting the extra days for the shop to overhaul his unit. When the replacement was installed, the shop found a sizeable compass error and to set-up the new HSI, a wet compass calibration had to be performed first. Then the tedious task of fine tuning the flux and compensator began, which requires a technician to crawl into the tail section and adjust components while another drives the airplane around the ramp lining up on cardinal headings. To make a long story short, this required several hours of billed shop time that the owner wasnt expecting.

The moral of the story is this: due to the time and expense of removal and reinstallation, we usually recommend overhauls of complex gyros rather than basic repairs. One Cessna 337 owner told us he had a shop remove his horizon gyro four times in two months to fix lazy erection. In desperation, he finally did what he should have done at the outset: bought a full overhaul on an older instrument that definitely needed it.

don’t be surprised to see substantial freight costs on your gyro repair invoice. The repair and exchange market spans the country and if youre AOG, overnight shipping in both directions can add up into the hundreds of dollars. Containers for shipping fragile instruments need to be large-and are billed as dimensional weight-to avoid damage during shipping. Second, declared insurance value must be high enough to cover the cost of replacing a damaged gyro. Insist on it. A while ago, we saw a UPS driver toss a $10,000 gyro off the back of his truck, despite a handle-like-eggs label. The box was refused, the gyro likely damaged. And it was.

Conclusion

If your airplane is flown in serious weather, your very life depends on your gyros. This is not a place to defer or scrimp on maintenance. In confronting a major gyro repair-a horizon for the autopilot or an HSI-we favor using a major shop, such as Mid-Continent in Kansas and California, JDC in Texas and Florida or Castleberry in Texas. If your tech recommends a local shop whose reputation hell stand behind by dint of experience, so be it. But ask about warranty and the availability of loaners and know what the overhaul price covers in terms of standard parts replaced.

If your major gyro has been in the panel awhile-say, more than five years-consider a pro-active overhaul and by all means go for the overhaul if the instrument shop recommends it. Piecemeal repairs might payoff but we think theyre more often a crapshoot on time, expense and aggravation. Ask your shop to provide a removal and reinstallation budget so you can gauge what itll cost to do repairs two or three times if the first attempt doesnt fix the gyro.

Minor gyros-ordinary DGs, turn coordinators and turn-and-bank indictors-are cheap enough to simply replace with new or exchange units. Overhauled exchanges might represent the best value since larger shops tend to have them in stock for quick shipment when youre AOG. In the end, as with everything else that breaks on an airplane, getting back into the air with the most cost effective and reliable fix is the overarching goal.

Also With This Article

“Checklist”

“Sample Gyro Overhaul Costs”

“Avoid Failures: Clean Your Carpets”

-Larry Anglisano is Aviation Consumers avionics editor.