Yes, we’ve heard all of the disparaging remarks: Magnetos have been around since there was dirt; they’re the trailing edge of technology and general aviation would proceed into broad, sunlit uplands if mags were to be consigned to the scrap heap and replaced with electronic ignition.

Nevertheless, while we think that electronic ignition is great and the replacement of at least one mag pays for itself—we’ll be doing an article on electronic ignition in the next few months—magnetos are going to be around for the foreseeable future, so it’s wise to learn about how they work as we’ll as their care and feeding.

Our end-of-the-day conclusion after talking with maintenance technicians, mag shops and pilots who have had mag issues is that they are quite reliable but that proper care is essential. That means recognizing that they are not going to last even close to engine TBO and that those folks who are recommending that they be pulled off the engine at 500 hours, inspected and repaired really know what they’re talking about. A full overhaul is almost never required, just inspect and replace components as necessary (IRAN).

Maintenance shops we talked with said that mags will almost always go 500 hours without a problem, but as they approach 700 hours in service the chance of one developing an issue starts to go up radically.

FOLLOW THE GUIDANCE

We think that guidance should be taken as a hard truth because magnetos generally do not give any warning of failure and some failure modes will cause an engine stoppage and/or catastrophic damage and engine failure in a matter of seconds.

In a conversation with Dave Parker, a backcountry pilot, A&P, IA and proprietor of Northern Air on the Boundary County Airport, Idaho, while researching this article, he told us that he will not take an airplane into the backcountry if it has mags that have more than 500 hours on them.

Do we have your attention?

Having mentioned the bad stuff, we’ll drop back to our guidance on mag care—if they are pulled at 500 hours in service, inspected and needed repairs made, they should soldier on happily for the next 500 hours.

Some years ago I was at Electroair’s (www.electroair.net) facility in Michigan learning about its electronic ignition for aircraft engines. Company owner Mike Kobylik said that he had recently gotten a call from a flight school that had replaced one mag with Electroair’s system in all of its trainers. It seemed that a solo student out in the practice area had experienced a very rough-running engine. She did a mag check and discovered that the engine ran smoothly on the electronic ignition but shook like crazy when the magneto was selected.

She left the ignition switch on the electronic ignition only position, shutting off the magneto, and headed back for home base, a towered airport. Inbound she advised ATC of an engine problem and landed without incident.

For reasons I did not learn, the FAA got involved and an inspector was critical of the flight school for teaching—and the student for doing as she was taught—to go to single-ignition operation when the engine runs rough and a mag check discloses that it will run smoothly on one magneto but not both.

I was astonished—I thought that every pilot knew that when an engine misfires and/or runs rough on one mag and not the other, then the pilot should select only the mag on which the engine runs smoothly. Apparently that’s not so. It took a conversation between Kobylik and the FAA inspector to get the inspector to recognize that the student pilot did precisely the right thing.

Then, about a year ago, I read an article that Savvy Aviation Maintenance Management’s (www.savvyaviation.com) owner and maintenance guru, Mike Busch, wrote for AOPA. Busch’s company tracked magneto distributor gear failures in a fleet of 300 airplanes over two years. In that time there were six failures. That type of failure causes teeth-shaking rough engine running (more about that in a moment) and potential engine failure. In each case the pilot declared an emergency and landed. In none of the cases did the pilot troubleshoot the problem and shut off the bad mag.

That floored me.

Our airplanes have a dual ignition system so that one can be shut off if the other malfunctions. And, because some failure modes of magnetos—notably loss of a tooth on the plastic distributor gear—will cause the spark plugs to fire randomly, that can destroy the engine. Hey, just firing 10 degrees early will run CHTs so high that the engine may fail catastrophically as cylinder(s) come off and/or holes are melted in pistons.

So, we’ll say it here, loud and clear. If you have a rough-running engine, troubleshoot the problem. One step in that troubleshooting checklist is to do a mag check. If the engine smooths out on one mag and the roughness returns on the other—do not let that mag that is causing the roughness continue to function.

Shut it off.

Position the ignition switch so that only the mag on which the engine runs smoothly is operating.

It’s OK to do that. You are hereby authorized to complete a flight on one mag when the other doesn’t like you any more and is trying to scare the bejabbers out of you by making the engine shake badly. You are not violating an FAR. You are not doing anything wrong by shutting off a bad mag. The airplane will not fall out of the sky because it is running on just one mag.

All we’ll say is that after you land, get the bad mag fixed. Don’t depart with only one mag working. After all, one of the hoariest axioms of aviation is that if you take off with one part of a redundant system out of service, the other one will fail.

MAGNETOS 101

OK, they’re black boxes with wires attached and they somehow are essential to that reciprocating thing the engine does. What goes on inside the box and why do they need to be inspected and, potentially, repaired, before my engine reaches TBO?

For the engine to ignite the fuel-air vapor charge in the cylinder and release the stored energy of the gasoline, the spark plugs for that cylinder have to be provided with enough electrical energy, at the right time. That’s where the magneto comes in. It makes its own electricity—a good thing if your airplane’s electrical system decides to take a vacation or if you have one of those cool airplanes that never had an electrical system installed.

A magneto works because a rotating magnet generates an alternating current in a coil of wire. When a second coil, with many more turns, is wrapped around the first (primary) coil, the voltage generated can be stepped up intensely.

In the mags we fly, the high-voltage current in the secondary coil is impressive—20,000 to 30,000 volts. That voltage is directed, by the magneto and ignition wires, to the spark plug as its piston reaches 20-24 degrees before top dead center (TDC). The spark plug does its thing, the fuel-air mixture ignites and the piston is pushed away from the explosion, turning the crankshaft and propeller. Flight generally results.

In a magneto, a permanent magnet might be considered its heart. That magnet is rotated by a drive on the engine’s accessory case. On a four-cylinder engine, it rotates at the same speed as the engine; on a six, it spins at 1.5 times the engine speed.

PERMANENT?

A permanent magnet in a magneto isn’t permanent, just as the hairstyle labeled a permanent doesn’t last forever. However, the magnet does retain its magnetism for years, and is re-magnetized when the mag is opened for overhaul or repair. That’s one reason a mag won’t last until engine TBO.

Maintenance technicians we spoke with said that calendar age of a magneto matters when it comes to the permanent magnet. If the mag has only 400 hours on it in 20 years, trying for another 100 hours over the next 5 years is not wise.

As the magnet losses its oomph, the electric current it generates diminishes. That results in a less powerful spark, which manifests in hard starting as we’ll as a slight power loss—both of which will progressively get worse.

The primary coil consists of about 200 turns of heavy-gauge copper wire. One end is grounded to the magneto’s case. A set of breaker points lives on the other end. They are operated by a cam. The breaker points spend most of the time closed so that the current generated in the coil by the spinning rotor flows around the coil and produces a strong magnetic field.

FIELD COLLAPSE

The cam that opens the breaker points is set to act the moment ignition is desired. When the circuit is broken by opening the points the magnetic field in the coil collapses—that causes a voltage spike in the primary coil of 200 to 300 volts.

One of the challenges to longevity of a magneto is that the breaker points cannot move from fully closed to fully open instantaneously. That means that during some portion of their travel the electrical energy will be capable of arcing across the opening. The arcing causes the breaker points to pit and erode—which is one of the causes of magneto mortality—and the need to pull and inspect at 500 hours.

To fight arcing across the opening breaker points—and cause a faster, more predictable magnetic field collapse and greater voltage spike—a capacitor is wired into the primary coil circuit. When the points begin to open, the initial voltage spike charges the capacitor for microseconds rather than jumping across the increasing point gap. By the time the capacitor is charged, the points are far enough apart that a 300-volt spike can’t jump the gap.

Of course, should the capacitor slip its mortal coil, arcing happens, along with pitting and erosion of the breaker points and eventual mag failure.

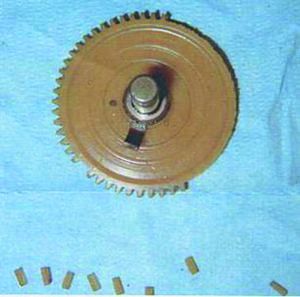

Once the voltage spike in the primary coil has been stepped up to 20,000 to 30,000 volts in the secondary coil, that energy needs to be channeled to the correct spark plug. That is accomplished mechanically, by a distributor. A rotating wiper electrode on a plastic gear inside the distributor passes near—without touching—the individual electrodes that connect to the individual spark plug lead wires. Distributor components, other than lead wires, are made of insulating material that can withstand the high voltages of the system—however, as with many engine components, they can be damaged by heat.

Because of the nature of conductivity of materials and how it can and will cause arcing between the rotating wiper electrode and the electrode connected to the spark plug lead wires, the interior of the distributor must remain almost computer server room clean. Arcing in the distributor can cause ugly results, notably engine misfire—which can damage or destroy an engine. Plus, once arcing starts, it makes itself worse. Arcing leaves a trail of carbon from the burned contamination—and that carbon trail causes further arcing.

A MATTER OF TIMING

The magneto has to send the high voltage shot of electricity to each spark plug at the right split second, every single time. That means that the mag has to be timed internally and externally.

To set the internal timing, the magneto has to be removed from the engine and opened up. Another reason that a mag should be pulled and inspected every 500 hours.

Internal timing involves setting the point gap and “E-gap” (“E” is short for efficiency). The point gap is set first. It involves rotating the drive shaft to the position where the breaker points are opened as far as they will go. The gap is measured with a feeler gauge and adjusted to the distance called for by the manufacturer.

The E-gap is the number of degrees of rotation between the magnetic neutral position of the rotor and when the points just begin to open. The purpose is to have the breaker points open when the magnetic field induced in the coil by the rotor is at its maximum and thus create the hottest spark.

EXTERNAL TIMING

External timing is performed with the mags on the engine and is ordinarily done at the annual inspection and during 100-hour inspections.

The process involves pulling a spark plug in the number-one cylinder and rotating the crankshaft until the number-one piston is at the firing position specified for that type engine—usually 20 to 24 degrees before TDC. The technician then uses an ignition timing light connected to the mag’s P-lead terminal while adjusting each mag by loosening its base clamps and rotating the mag on the mounting pad until the timing light indicates that the points are just beginning to open. The tech then tightens the clamps and checks the timing again because the mag may have moved.

We have seen damage done to engines when the magnetos were mistimed. Advancing the timing a few degrees more than called for by the manufacturer will cause the engine to run hotter and reduce the detonation margin. Timing advanced by just four or five degrees on a big-bore engine, combined with a hot day, has caused detonation on takeoff and engine destruction shortly after.

Advanced timing can be an expensive event even on smaller engines. We looked at a Cessna 150 that needed all four cylinders replaced because they melted after the timing was mis-set at the annual and the airplane did not have an engine monitor that would have shown the excessively high CHTs.

CHOICES

There are only two manufacturers of mags. Depending on your type of engine, you may or may not have a choice.

First: Bendix mags—now manufactured by Continental—come in three main types. The S-1200 series are large, robust, hot-sparking mags that are often used on airplanes that fly at high altitude. They do not fit on all engines. The S-20/S-200 series are older, smaller mags that have a good reputation in service. The D2000/D3000 series are “dual magnetos”—two magnetos driven via a single shaft. They are used only on Lycoming engines that have an engine number ending in a “D” suffix, and Continental no longer supports them.

We’ve been doing a mag check ever since we taxied out on our first flight lesson. We learned to shut off one mag, note the RPM drop, return to the both position, then shut off the other mag—making sure that the RPM drop and difference in drop between the two mags did not exceed the specs in the POH.

More recently we have learned that it’s better to focus our attention on the engine monitor, rather than the tach, during the mag check. When we change from both mags to one, we should see all of the EGT bars on the monitor rise—and none fall. The rise should be between 50 and 100 degrees F, be stable, and the engine should continue to run smoothly.

A faulty plug or ignition lead only affects one cylinder—and one EGT bar. A faulty mag affects all of the cylinders and EGT bars.

A falling or erratic EGT bar means not flying until the ignition system is troubleshot. If the issue is a non-firing plug, the cause is most likely to be oil fouling. It’s often possible to rectify the problem with a 30-second runup leaned to peak EGT (or max RPM). If that doesn’t fix things, the plug is probably lead-fouled or damaged. It should be inspected and cleaned or replaced before flight.

Because the pretakeoff mag check is fairly non-demanding on the ignition system, it will only detect big problems in the ignition system. To catch small problems before they become big, we recommend periodically doing an inflight mag check at altitude when the engine is developing cruise power and the mixture is leaned. Under those circumstances the ignition system is under maximum stress (especially if operating lean of peak EGT) and little problems are more likely to be uncovered. Doing the check just before starting the descent into home plate is a good way to discover issues so that you can get them repaired prior to the next flight.

During the inflight check, run on each individual mag for at least 20 seconds while observing the engine monitor in the normalize mode. All EGTs should rise and remain stable and the engine should run smoothly. Pay primary attention to the EGTs while being alert for any engine roughness.

Write down the cylinder number if you observe any falling or unstable EGT—so you and your mechanic will know which plug is the culprit.

If you observe a non-firing plug on an inflight check, don’t worry. The engine will not be harmed by one cylinder running on only one plug. If the engine is running smoothly on both mags, leave the switch in that position, make a normal descent and landing and then pay a visit to your shop.

It really is OK to do a mag check while you are in flight. It might feel a little spooky the first time or two, so do it slowly and deliberately to avoid shutting off both mags. If you happen to do that, pull the power back to idle before switching the mags back on. When the engine restarts, reset the power and press on.

DUAL MAG

The original D2000 mag was not reliable. Our nonscientific review indicated that there are few in use—they’ve been replaced by the D3000. Short background—the dual mag consists of two independent magnetos packaged in one container, albeit with a single drive shaft and mounted on a single pad on the accessory case. The original goal was to take up less space and reduce gear train complexity on the back of the engine.

The FARs require (simplified) that spark ignition engines have a dual ignition system with at least two spark plugs per cylinder and separate electrical circuits with separate sources of electrical energy. The dual mag complies with the regs; however, it still has a single point of failure—the impulse coupling that drives the dual mag from the engine gear train.

Our search of national specialty shops showed prices for Bendix mags were in the $725-$1123 for factory overhauled units and twice that for new.

CHAMPION/SLICK

The other mag manufacturer is Champion, which makes what were formerly known as Slick mags. They are smaller than comparable Bendix mags and less expensive.

Our most recent review of prices revealed prices for overhauled Slick mags in the $1000 range, with new from $1859 to $2049.

IRAN

As we said above, when your mags hit 500 hours in service, we recommend yanking them and sending them out to a specialized shop for IRAN. We suggest IRAN rather than overhauling as an IRAN involves inspecting and replacing parts only as needed. An overhaul requires that the shop replace all of a specific list of parts, even if some or all of them are serviceable.

Depending on the number of parts to be replaced, we were quoted prices for IRAN of Slick/Champion mags in the $500 range and $700 for Bendix/Continental mags, except for the dual mag—we heard a range around $1200. Bendix mags can be IRANed indefinitely; they do not need to be overhauled.

Maintenance techs we spoke with said that they no longer do IRANs in-house, but send the mags out to specialty shops as those shops can turn mags faster and less expensively than they can do them in-house, even with shipping. The techs unanimously said that the ability of the mag specialty shop to communicate is the main driver in which shop they use.

HIGH-ALTITUDE MISFIRE

As an airplane climbs and air gets thinner the insulating properties provided by air in a magneto diminish, making arcing and misfire more likely. Our one experience with misfiring in the flight levels was scary. The immediate solution is to reduce power and descend.

Reducing power reduces combustion chamber pressure and reduces the stress on the spark plugs, making it easier for them to fire. That reduces the potential for arcing in the distributor. As the air density increases, the increased insulating property of the air should stop the misfire.

After landing, pull and open the mags and inspect for carbon tracking inside the distributors. Any found should be cleaned out as leaving it will make things worse next time.

Airplanes regularly flown high usually have the largest possible mags installed—so there is the greatest distance between spark plug lead electrodes. The alternative is installing pressurized magnetos. Our review of the subject indicated that going with a big mag is the better alternative, if there is space to do so.

Pressurized mag systems are more expensive than big mags, add complexity to the system and can introduce contaminants into the mags, upping the risk of arcing and misfiring. In addition, pressurized mags have a single point of failure that will affect both magnetos: They are supplied by a single pressurization hose and single pressurization filter. Failure of either depressurizes both mags and can cause high-altitude misfire and loss of the engine.

CONCLUSION

While we wait for an affordable, certified electronic ignition system for our bugsmasher, we’re going to keep using magnetos because they work.

However, we have to accept that components wear and wear out—so plan on pulling them every 500 hours for IRAN or replacement (depending on cost).