Talk about the current market of new million-dollar piston singles and inevitably someone will argue that you could buy a twin turboprop for less. The Cessna 425 Conquest I is one of them.

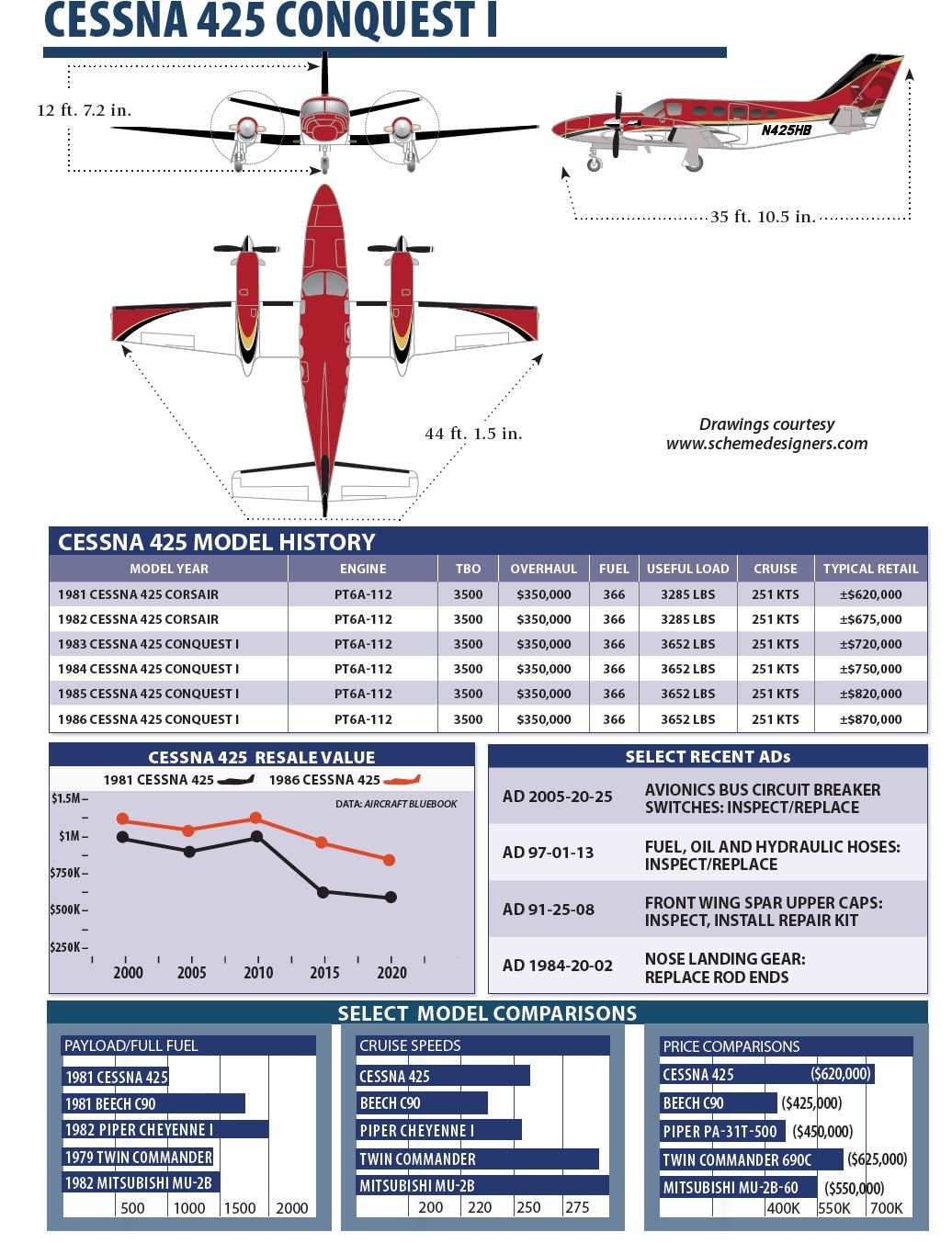

The current Aircraft Bluebook pegs a 1981 425 at $620,000 (down $200,000 from ten years ago), and for those looking to move into the world of Jet-A-burning twins, the Conquest is worth a look. The airplane has a reputation for being a relatively easy step-up turbine—if not a logical step—for eventually moving into a Cessna Citation jet.

The Cessna 425’s strengths are relative economy with good performance, including balanced-field numbers, excellent handling characteristics, a well-designed cockpit for flying single-pilot, good CG, good loading options and a comfortable bizjet-like cabin.

Of course we don’t have to mention that a Conquest ownership (or any twin turboprop for that matter) won’t be cheap—from fuel burn to maintenance to engine swaps ($350,000 per)—but we will anyway. But among twin turboprops, a Cessna 425 “baby turboprop” may be one of the least expensive ways to get into the world of turboprop twins. Its direct competitors might be the Piper Cheyenne I, a Beech King Air 90 and even some turboprop singles. Here’s a fresh look at the market.

HISTORY LESSON

Before the Conquest, Beech had been busy cranking out its King Air line since the mid-1960s, while Piper gained FAA certification of its first Cheyenne model in 1972. Cessna, perhaps nodding to Beech’s preeminence in the market, leapfrogged turboprops altogether, preferring to put its development dollars into the Citation line, a move that’s paid off nicely. But the 1970s were almost ready to yield to the 1980s before Cessna type-certificated its first turboprop, the Model 441, in August 1977.

Now known as the Conquest II, the Model 441 was an evolution of the Model 404 Titan, a piston-powered twin, powered by Garrett (now Honeywell) TPE331-8 series turboprop engines. Confusingly, the Model 425—eventually dubbed Conquest I—earned its type certificate almost three full years later, and started life as the Cessna Corsair. Itself an evolution of the very successful Model 421, the 425 was powered by venerable Pratt & Whitney Canada PT6A-112 engines.

Before production of Cessna’s “baby turboprop” ended in 1986—along with a lot of other models from among the GA manufacturers—some 236 Model 425 Corsair/Conquest Is were produced.

By the time Cessna was able to certify the Corsair/Conquest I in July 1980, general aviation production had peaked, and Cessna itself had been going through some very difficult years. Several of its high-performance twins were suspected of design errors that led to inflight airframe failures. These included the 441, its piston-powered kin the 404 Titan and the Model 340. Expensive ADs were applied while the company tried to fix the problems: All early Model 441 airframes were upgraded to a later configuration by the factory, at its expense. Meanwhile, the 340’s empennage had to be inspected every 10 hours of operation for a period of time.

IT’S NOT A TURBINE 421

One of the elemental strengths of the 425’s design is the nearly bulletproof Pratt & Whitney Canada PT6 free turbine engine. The A-112 version originally installed in the 425 is a fairly unsophisticated one that is not highly stressed. It is flat rated at 450 SHP. For pilots transitioning to turbine power and for operators at smaller airports, PT6 power is the right choice and is easy to support. The inflight shutdown rate is impressively low, which is why so many pilots call the engine bulletproof.

The Conquest is not a model 421 with PT6As—not by any stretch. The 425 is its own airplane, even though a handful of Continental GSIO-520N-powered Cessna 421 Golden Eagles have the Riley 421 Prop Jet conversion. This includes Honeywell LTP-01 engines and winglets. But there are a number of distinctions, and very different systems were installed in the Conquest. It would make about as much sense to call a 421 a pressurized 411, or a 414 a wide-body 340. But make no mistake, all are products of the same basic design and engineering philosophy, and the later 400-series airplanes reflect many of the lessons learned in designing, developing and building the 500-series Citations.

The wingspan of the 425 is about three feet wider and the wing area is 10 square feet greater than the 421 wing. The 425’s horizontal stabilizer has a distinct dihedral (and, as a former senior Cessna official later said, it really should have been a cruciform tail to negate the adverse effects of propeller wash, now often called whirl-mode vibration, but the company did not want to spend the extra bucks). Still, the aft fuselage structure is much beefier than that of the 421. Just count the rivets from the cabin door aft on the two airplanes.

True, many performance numbers are fairly close for the two types. But that is at a takeoff weight of 7450 for the 421 and 8600 for the 425—more than half a ton of difference. Basic empty weights are about 250 pounds different, but the 425 lifts nearly double the fuel weight of the 421 (2452 versus 1236, or 1572 with auxiliary fuel on the 421). Both all-engine and single-engine rates of climb are fairly close (1950/345 for the 421 and 1875/380 for the 425). The 421 wins the accelerate/stop race (3630 to 3800 feet), but the 425 runs away in accelerate/go (4960 for the 421 to 3360 for the 425). For the love of turbine power.

The 425 also has the advantages of propeller reverse and autofeathering—a no-go system, by the way—the latter of which greatly simplifies aircraft control in the event of an engine failure.

At comparable weights, of course, the power and higher aspect ratio wing advantages of the 425 enable it to run away and hide from its piston-powered cousin. Then, compare the inflight failure and unscheduled removal/repair rates of the two engines. It’s no contest: The turbine is far superior.

For the properly trained pilot of a well-maintained airplane, the superior systems and performance of the 425 result in greatly reduced workload compared to the 421 or any other piston twin.

MAKING IT BETTER

At its introduction as the Corsair, the 425 had a maximum takeoff weight of 8200 pounds and a basic empty weight of 4870. Full usable fuel weight of 2452 pounds (366 gallons) and average optional equipment weight of 375 pounds left a pretty miserly 503-pound payload.

Maximum takeoff weight was increased to 8600 pounds in 1983; basic empty weight increased by 52 pounds, leaving most of the increase for payload. At the same time, the 425 was formally inducted into the “Cessna Propjet” family and was renamed the Conquest I. No more privateering.

Earlier 425s could be modified to the new weights quite easily, and all have been. Zero-fuel weight increased from 6740 to 7000 pounds; maximum landing weight remains 8000 pounds. Most other changes to the 425 are system or operationally related, such as improved static wicks and additional avionics options.

Probably the most important of the latter is the optional Sperry (and later Honeywell) SPZ-500 flight control system. Even for its $75,000 cost at the time, it was a big improvement over the ARC (Cessna) 1000 FCS, which has been one of the weak links in the 425 and other Cessna twins. Some 425s were equipped with the ARC 800 series autopilot, which is even less desirable than the 1000. One owner told us the 800 in his airplane had a mind of its own despite many attempts to correct its abrupt pitch excursions. We’ve had our hands in these systems enough to know labor and parts costs for troubleshooting and repair can be a big number. Evaluate them carefully during a prepurchase run-through.

From the beginning, Collins avionics have been an option worth the price differential over the standard ARC system. To be fair, it should be noted that a number of operators had good experience with their ARC avionics (and a Cessna technician, when asked about his early experience with the 425, said everything was great except for the (expletive) Collins radios. If you find one with Collins or ARC avionics, we would budget $100,000 to start for a full-up avionics retrofit, and likely more if you replace the autopilot. Common upgrades, including the Garmin G600 TXi primary flight display, S-TEC digital autopilot and Garmin GTN navigators. Don’t forget ADS-B transponders.

It may be time for some panel work, too. As a requirement for British certification, a master caution warning system was added. This is a useful addition because the annunciator panel can be hard to see in direct sunlight, even though it is mounted at the top of the panel, under the glareshield.

A noticeable improvement was made in the later run of 425s: better interior design, fit and finish. Appearance, comfort and durability all were improved. Redesigned cabinetry also provided more legroom for passengers in the principal four club chairs.

Another factory option made available in 1982 was Cessna’s Cescom maintenance program, which recently was turned over to CAMP Systems. A genuine programmed maintenance scheme in its later form, Cescom provided more flexible inspection options that could reduce total hours and cost for those who scrupulously followed the recording and reporting requirements. A service life recorded on Cescom would be a strong plus for any used 425. Regular readers of aircraft resale advertisements will note that such programs as Cescom, various engine maintenance programs and good service bulletin compliance history are considered sales advantages.

A number of improvements have been missed by operators who do not carefully review product information and improvement and service bulletins from Cessna and component manufacturers. These include glass replacement windshields (although some technicians claim this change has not completely solved cracking and delamination problems), replacement of troublesome torque gauges with electric ones, water drains to control circuit breaker and avionics systems contamination and shorting, plus a number of engine modifications.

The best Conquest I is one fully up-to-date on hourly, cycle and calendar maintenance, ADs, service bulletins and kits, product improvements, updated electrics, current avionics and a sound pressurization and climate control system. This could run into real money. How much?

When shopping, consider that Aircraft Bluebook suggests dinging the price by $112,000 if the SIDS (Cessna Supplemental Inspection Documents) aren’t complied with. It should also pass the most meticulous, every-nook-and-cranny inspection by an experienced 425 technician. The best-looking Conquest I, with the newest interior and latest paint job, may be a beast in disguise. Cosmetics are appealing, but they are the least important part of any airplane purchase, especially something as complex as a Conquest. There are many thousands of buyers who were lured by good looks thinking the airplane was good to go, only to find they had bought hangar queens.

PERFORMANCE, LOADING, CABIN COMFORT

While the 425 does not have the payload capacity of a C90 King Air, it is nearly a fill-the-seats airplane. With lots of lard and luggage toward the rear of the airplane, CG has to be checked carefully, but the loading range is quite wide.

Zero-fuel weight dictates that anything between 7000 and 8600 pounds has to be fuel, but that still leaves a healthy payload of crew, passengers and baggage or freight of 1673 pounds for a typically equipped airplane.

The average 425 can seat eight: two in the cockpit, four in club seats, and two in the additional full seat on the left rear side of the cabin and belted potty seat. Even with the maximum number of seats, there is a generous baggage area in the aft cabin (about 30 cubic feet and up to 500 pounds). The cavernous nose houses another 22.4 cubic feet of baggage area with a maximum load of 400 pounds. It’s a big airplane.

There is a lot of cubic space in both the cabin and baggage areas that could tempt those lacking caution and experience to exceed load limits. Yield not to that temptation. Aside from CG concerns, exceeding maximum loads can cause serious performance deterioration, especially in high density altitude conditions.

With sea-level, standard-temperature conditions and gross weight the (well-flown) 425 can clear a 50-foot obstacle after a run of 2420 feet and land over the same barrier in 2120 feet. With the already mentioned accelerate/stop and accelerate/go distances of 3800 and 3360 feet, a properly qualified pilot can safely operate from 4000-foot runways with room to spare. If you are used to flying a Skyhawk or a Cherokee, that may sound like a lot of runway. For a nearly 9000-pound airplane, however, that’s pretty good.

Rate of climb is good enough to make it practical to climb into the flight levels for even relatively short trips. The 425 operates best between FL230 and 280. While maximum speed of 260 knots comes at 18,000 feet, fuel burn is high. At FL260, max cruise power produces 251 knots and 1240-NM still-air range. In the mid-20s, the 425 is a five-hour-plus-reserves airplane. With a maximum operating speed of 230 KIAS and max gear operating of 175 and approach flaps of 174, the 425 can return to pattern altitude quite quickly when necessary.

A Conquest with well-balanced rotating components and a fully functioning propeller synchrophaser can be relatively quiet and comfortable at cruise power settings, especially at propeller RPM of less than 1900. Each airplane has an ideal, low-vibration RPM that can be determined with practice. Good propeller balancing makes it even better. For a number of 425s, the best compromise of noise and vibration occurs at propeller settings of between 1825 and 1850 RPM. Experimentation pays off, because once cruise power is established, vibration is more of a noise-generating factor. The two major sources of noise both involve propeller vortices: hitting either the nose cone or the tail, and then being transmitted to the cabin (the fuselage acts like a megaphone).

The 425 is a good airplane with respect to noise and comfort.

We looked hard at Aircraft Bluebook values for same-class turboprop twins—the 425 Conquest I, Piper Cheyenne I and Beech King Air C90—and discovered an eye-widening pattern of depreciation over a 10-year period. The Conquest was introduced in inauspicious times. Since then, single-engine turboprops like the Pilatus PC-12, Daher TBM series and Piper Meridian/M-Class singles have come onto the market, offering similar performance (except when an engine fails), fully integrated avionics and autopilots, similar cabins and around half the burn of Jet-A. All of which nearly drives a new turboprop twin to extinction, evident by the huge slide in resale values of twin turboprops starting around 2009. The 425 Conquest wasn’t the only turboprop that took it on the nose, and that’s all good for buyers in 2020.

According to Aircraft Bluebook, even the Beech C90 King Air book value has steadily declined in big numbers. Ten years ago a 1981 C90 had a typical retail of around $900,000. Today it’s published at $390,000. A 1981 Piper Cheyenne I once valued at $550,000 currently lists for $230,000.

These are starting values, of course, because major upgrades and refurbishment are a huge factor in ultimate fly-away pricing. Just as it is in the lower end of the market, planes that have been upgraded with modern avionics, paint and interior end up selling for a lot more. The same goes for the Conquest, where major renovations aren’t uncommon. We looked at the respected aircraft sales website Controller.com and found wild price swings. For instance, a 1982 Conquest I with 7400 hours on the airframe and 1100 hours on the PT6A-112 since major overhaul was listed at $690,000—which is in line with Aircraft Bluebook suggested retail prices. On the other end of the spectrum, there was a 1983 model listed for $1.4 million. It sported fresh Blackhawk XP135A engines (PT6A-135) with four years/2300 hours remaining on the warranty, relatively low airframe time (5800 hours and 4500 landings), new Garmin glass avionics with ADS-B, cabin Wi-Fi, paint from 2002 and incremental interior upgrades including new cabin seating. The Blackhawk mod has a factory-new list price of $750,000, and core engine credits can be up to $35 per hour per engine for every hour remaining on the factory TBO, which for the PT6A-112 is 3500 hours. Blackhawk advertises that nearly every Blackhawk-powered aircraft that has been resold within 500 hours of the upgrade has sold close to or higher than the combined investment of the airframe and engines. That’s pretty much what we saw in our research.

The other thing we see is that despite the comparatively small population, the market for used 425s remains active and, for the most part, the airplane is favorably regarded. For a properly maintained airplane, dispatch reliability is high, and operational simplicity makes it comparatively undemanding to fly. With prices now stable, we think the right Cessna 425 Conquest I is a good used market value.

SINGLE-PILOT CAPABLE

But only if you are. Our accident scan uncovered a surprising number of issues in IMC, proving that while the Conquest 1 has a reputation for being an easy turboprop to fly by yourself, bring the A game.

The reward for doing so is a cockpit with decent ergos, made even better by modern electronic displays that bring lots of data in a centralized location. The cockpit dwelling is also comfortable for most pilots of average to large size. Visibility is good. Control harmony in flight is fair. Pitch is the heaviest force, and this is by design. Appropriate trim input is a key to flying the 425 smoothly.

Even so, pitch changes resulting from configuration adjustments are modest. They are more obvious with power changes—particularly major power changes as when transitioning from approach to missed approach or go-around.

There are no peculiar tricks, however. From both the pilot eye-level perspective and physical/reaction demands, the 425 probably is the simplest of all the turboprops to transition to. Thus the nickname “baby carriage.” Pilots transitioning from light twins will have to get a feel for control pressures, trim use, aircraft performance and weight (inertia). But good training and a bit of experience quickly lead to confidence. Engine management, from startup to shutdown, is as important as how we’ll you can fly (or program it to fly) a busy approach in the clag. And you better mind those PT6As. Poor power management can lead to premature failure or, at the least, much higher hot-section inspection and overhaul costs. They cost big bucks.

Flying the airplane entails extra time and extra care during pre- and post-flight operations. There are good tricks to learn. For instance, if a quick landing and turnaround is planned, shutting off the bleed air source from one engine about 15 minutes out, then starting that engine first on the turnaround, means lower start temperatures and lower stress on both engines.

On the ground, both before and after flight, the airplane needs special care, and operations such as ground towing and refueling must be closely monitored.

We dug into Cessna 425 accident reports back through 1985 trying to find 100 so that we might do some meaningful analysis into problem areas with the fleet. We found a grand total of 27 mishaps of widely varying severity, including one poor pilot who had another airplane taxi into his turboprop.

We found no engine-failure-induced accidents, a tribute to the Pratt & Whitney PT6 powerplant.

One pilot did think he had an engine problem—a chip light illuminated—so he shut the engine down. He then landed short of the runway and tore off the gear. An inspection of the chip detector revealed that it was defective and had given a false chip indication.

There were only two fuel-related accidents. In one case the fuel was contaminated, leading to one engine going quiet, followed a few minutes later by the other. The pilot was almost able to glide to an airport and survived a landing in trees. In the other, the pilot noted a split between the left and right fuel gauges although he was certain that there was an equal amount of fuel in the tanks. He chose to believe the gauge that showed more fuel.

You got it, it was the other gauge that was correct. He was, however, right about the tanks having the same amount of fuel, as the engines quit at almost the same time. The accident investigator found that the left gauge showed empty while the right indicated 290 pounds of fuel.

Icing played a role in four accidents, including aviation’s version of a fender bender when a 425 slid off of an icy taxiway and hit a sign at low speed.

One pilot reported that after collecting ice, he was able to remove most of it with the deicing boots, but still chose (probably wisely) to tack on extra speed on approach to landing. He hit turbulence in the flare, which rolled the airplane in both directions. He attempted to go around, but stalled the airplane and a wing hit the ground.

To the extent that there was a common thread in 425 accidents, it was problems associated with flying IFR in IMC.

One 425 pilot collected so much ice that he stalled the airplane and spun it in.

The post-crash investigation into a 425 that was seen to emerge from cloud bases in a diving spiral before it broke up revealed that the left pitot heat switch had been damaged sometime prior to the flight. The pilot had turned it on prior to entering icing conditions, but it did not activate the system. The right side pitot heat was on and functioning. The pilot lost control after the left pitot tube froze up and he tried to deal with discrepancies between the pilot and copilot airspeed, altitude and VSI indications.

Of five accidents in IMC, three involved pilots who lost control of their airplanes and postmortem exams found significant levels of disqualifying prescription drugs in their bloodstreams.

Another pilot broke out of clouds on an ILS at 100 feet in a left turn, which he continued to ground impact.

A pilot who had his passenger crouch beside him to “help find the runway” on an ILS went we’ll below minimums before missing the approach. Rather than climbing, he then flew level into obstructions. The passenger survived. The pilot, who was not wearing his shoulder harness, did not.

Two pilots got things wrong with the power controls. When one brake failed on landing, the pilot feathered the props rather than commanding reverse and went off the end of the runway. Another, meaning to pull the power to idle before flaring to land, commanded reverse and hit hard, short of the runway and collapsing the gear.

MAINTENANCE, SUPPORT

This is not the kind of airplane to use for on-the-job training for technicians for your local or favorite but unqualified shop. That’s a major reason for unhappiness with the 425 and similar airplanes for many operators. Selecting the wrong shop can be as expensive as neglecting proper maintenance altogether. The best approach is to talk to other Conquest I operators to get their recommended service and information sources. Keep meticulous records, too. Get involved in an information-sharing network of operators and service/support organizations. It can serve as effective early warning and help keep operational readiness up and costs down. With all that in mind, any serious Conquest I buyer and owner should absolutely join the Twin Cessna Flyer organization (www.twincessna.org).

The known maintenance record of the 425 fleet, consisting mainly of service difficulty reports (SDRs) and airworthiness directives (ADs), has highlighted some shortcomings of the design. While there has been no overwhelming weak point, several problems identified in the field have resulted in ADs. There are a few that suggest careful inspection in hard-to-get-at areas is required. These areas include control cables at pulleys, fairleads and pressure vessel seals, and window retainers.

Service difficulties that resulted in ADs include wing spar cap cracks caused by landing gear loads (AD 91-25-8, repetitive inspection or replacement), windshield attach point failures (84-3-4, repair or replace the windshield), nose landing gear actuators (84-20-2) and horizontal stabilizer attach fittings.

On Sept. 1, 2007, Cessna introduced the Supplemental Structural Inspection Program (SID) for the Model 425, after working with Model 300/400 operators and the FAA. The program consists of the current structural maintenance inspections, plus supplemental inspections, as required, for continued airworthiness of the airplane as years of service are accumulated. The current inspection program is considered to be adequate in detecting corrosion and accident damage. The SID program’s emphasis is to detect fatigue damage whose probability increases with time.

Approximately 60 percent of the active 425 fleet (approximately 240 aircraft worldwide) has had the SID inspections accomplished, which are due on all aircraft over 20 years old (i.e., the entire fleet). The initial inspection requires the entire series to be completed, which is a sizable task and not to be accomplished by the average maintenance shop. The complete series of inspections involve 943 labor hours, plus nondestructive testing if completed simultaneously. Individually, there are 1685 labor hours of inspections, plus NDT.

Once the initial SID inspection is completed, additional inspections will only come due again over the course of 10 years or 5000 hours of operation. Only one minor inspection has been added to be accomplished every 200 hours of operation or 12 months, whichever occurs first. The vast majority of the inspection series repeats again in five years or 2500 hours of operation, or 10 years or 5000 hours of operation. A comprehensive explanation of the program is available from Textron Cessna technical support or an authorized service center.

At least the Conquest is not an orphan. Despite the fact no 425s have been produced for a few decades, operators tell us that Textron/Cessna support is commendable, particularly when compared to most other manufacturers or former manufacturers. Cessna service centers specializing in 400-series twins also can be a good source of research materials for determining what the proper maintenance status of a 425 should be. The few bucks (or hundreds of bucks for all materials) represent a worthwhile investment.

So, too, it pays to get to know someone in customer service at Pratt & Whitney (PWC). While the PT6A-112 is a fairly old and mild version, there is much to learn about modifications and recommended procedures. For instance, one reader who bought a 425 awhile back had a nearly $55,000 shock when discovering the original cobalt inlet guide vanes had been replaced by nickel vanes (that large payment included hot section inspections).

Basic changes have occurred—which operators on Cescom or on the mailing lists at Cessna and PWC would have known about—that increased propulsion system serviceability and durability (and reduced major maintenance costs). Among these are compressor washes. A mod was introduced that adapted a fitting much like the one on a garden hose to make compressor washes easier to perform.

PWC has a lot of eye-opening information for operators. Among these are some of the reasons for regular compressor washes. You might accept the necessity in a high salt-content environment. Pratt specialists can show you maps of concentrations of contaminants such as sulfur that occur at cruise altitude in parts of the North American continent, where you might expect the air to be pristine. Among the relatively simple modifications that can be made to the 425’s engines is one that reconfigures the inlet nozzles to reduce temperatures in the combustion section of the engine during starts.

What some operators of turbine engines never learn, and others learn only after expensive inspections and overhauls, is that heat is both the friend of performance and the enemy of endurance. Going for maximum performance all the time means running temperatures to the recommended limits. Given the vagaries of most gauges and the benefits of just a few degrees lower temperature, a little touch of conservatism can mean literally thousands of dollars of reduced cost during a hot-section inspection or overhaul, not to mention diminishing the stress that could result in one of those rare inflight failures.

Of course, much the same can be said for piston engines, from a big Pratt radial all the way down to a Briggs & Stratton.

OWNER EXPERIENCE

We have owned our 1983 Conquest I now for six years. With 10,500 hours on its clock it has full Garmin glass, including dual Garmin G600 displays, GTN 750 navigators, Garmin traffic and radar systems and an S-TEC 2100 digital autopilot. This Conquest was in fact the Garmin STC plane. Prior to the Conquest we owned a Cessna 421C for nine years and we still do, and we bought a Cessna Citation 501 three years ago so the Conquest I sits firmly in the middle. For speed, we tend to fly the Conquest at 18,000 feet and get 260 knots with a burn of 475 PPH, moderately loaded.

We’re sold on the Conquest being an easy turbine upgrade from the 421. It was a very easy transition as so much felt very familiar, and because so much of the airframe and the cockpit is similar. I’ve heard that Cessna upped the build quality, but we haven’t really noticed much between the two. The difference between the Conquest and the Citation, however, is significant and it is clear that the Citation 501 from the same era is built to a much higher standard in all respects.

This said, components seem to hold up much better in the Conquest. The turbine-powered airframe flies much smoother than the piston, and thus it’s not shaking itself to bits!

We have MT props on the airplane and they are definitely smoother than the alloy four- blade props they replaced, and quieter, too. We notice little difference in performance, although perhaps a bit slower in cruise (roughly 4 knots) and a slightly better climb rate.

The props were upgraded mainly for two further reasons. The plane originally had three-blade props and must have been upgraded to four-blade props due to harmonics, and the NG idle setting had to be turned up. The result is the plane pulls away on the ground during taxi and you are constantly either on the brakes, or in reverse. The five-blade MT props are set at the ordinal idle, so there’s no issues. Also the blades are about 9 inches shorter and can be ordered with titanium leading edges. We fly on a lot of country strips, sealed and grass, and the edges and length are a major help in avoiding FOD in the engines and chipped blades on the props. They are expensive, but probably the most important upgrade we’ve made to our 425.

Stuart Clumpas – via email