When the single alternator in a single-engine airplane decides to take the day off in the middle of a flight, the resulting unpleasantness spans the spectrum from inconvenience to terror depending on the weather and the endurance of the aircraft battery—and individual batteries for instruments and portable devices that can help the pilot keep the airplane right side up and heading toward a suitable airport.

While alternators are more reliable than vacuum pumps and some can be expected to perform we’ll beyond engine TBO, they do fail. We’ve had two give out at night in IFR conditions and a brand-new one expire within a month of installation (in VFR).

Enter the standby alternator. It’s a second alternator that is wired into the electrical system so that it comes online if and when the primary alternator goes off. We’ve watched the interest in retrofitting standby alternators ramp up and have been told by avionics shops that a number of their “out with the six-pack, in with the glass” customers are deciding to slap a standby alternator on the engine accessory pad where the vacuum pump used to live as part of the overall upgrade package. They want the additional peace of mind provided by the secondary power source in addition to battery backup.

A comment we heard more than once from pilots who fly regularly in the West where airports with instrument approaches can be a long ways apart—the idea of having but an hour of electrical power when the alternator goes out gave them the heebie-jeebies.

In addition, with the approval of Electroair’s electronic ignition to replace both mags, its need for a secondary power source has increased demand for standby alternators for those who want to get the full benefits of electronic ignition.

We wanted to see what’s offered for pilots who want standby power and how widely it’s available.

During our research we found two companies offering true standby alternators, and were a bit surprised at how limited the market currently is. However, as we expanded our search, we were pleased to run across a little-known company that offers standby electrical power in the form of a ram air turbine (RAT) that pops out of an airplane into the slipstream, much as RATs have been doing on jets for years. Plus, it appears that its turbine can be installed on a wide variety of single-engine airplanes.

CAVEATS

We’ll go through the suppliers of standby power devices we reviewed; however, before doing so, we note two caveats. First, none of the standby power sources provide as many amps as the primary alternator in your airplane. As part of the installation, we strongly recommend that you prepare a checklist of the electrical equipment that can be driven by the standby power source so that you can reduce the load quickly if you have to use standby power. You don’t want to run the battery flat even though you have a secondary source of power.

Second, before you purchase a standby alternator, make certain that it can be installed on your particular airplane. We understand that some of the Lycoming-powered Cessna 182s and 206s have the pad where a standby alternator can be mounted but there is no gear installed under the pad for the engine to drive the alternator—and installing that gear is an expensive and time-consuming process that involves pulling the engine. If you are planning to put the alternator on the pad where the vacuum pump was, there should be no problem.

B&C SPECIALTY PRODUCTS

Starting life in the 1980s in the experimental world, B&C Specialty Products (www.bandc.com) of Newton, Kansas, branched out into building standby alternators for certificated aircraft in the 1990s. Its standby alternators have been standard equipment on Bonanzas since 2000.

The company now offers STC’d 14- and 28-volt, 20-amp standby alternators for the Beech Bonanza line (1958 J35 and later), Cessna 210 and T210 L, M and N models and the Piper PA-32 line (Lance, 6, Saratoga series). B&C says it will work with owners to obtain field approval for one-off installations on other aircraft.

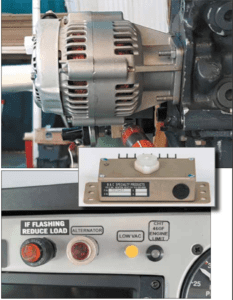

The system is similar for all models. The standby alternator is mounted on an engine accessory drive pad and wired into the electrical system. Switches and circuit breakers for the standby alternator are added to the instrument panel—the complexity of the installation varies by aircraft.

During engine start the pilot turns on the primary alternator and battery and also the standby alternator. The standby system then monitors the aircraft bus voltage in the background, automatically signaling its operation to the pilot through a panel-mounted annunciator light. If the primary alternator fails, the standby system will sense the drop in bus voltage and automatically activate.

Once activated, the odds are that the electrical load demanded will exceed the 20-amp capability of the standby alternator. If that is the case, the panel-mounted annunciator light will flash, alerting the pilot to reduce the load. That will preserve battery energy for transient loads such as gear and flaps.

B&C says that the load may be beyond the 20-amp flashing alert point for up to five minutes without damaging the standby alternator.

Price for the Bonanza standby system ranges from $3165 to $3940, depending on accessories needed for the particular airplane, notably those with electroluminescent switch panels. Bonanzas with air conditioning may require that the compressor mounting casting be modified for clearance with the standby alternator. That requires that the bracket be removed, all hardware removed from it and then sent to B&C for modification.

Price for the standby alternator system for the Cessna 210 and T210 L, M and N is $3,365.

On the 210, the standby alternator is mounted on the right-hand accessory drive pad to allow throttle linkage clearance. That is where the vacuum pump is normally mounted. If it is not to be discarded, it must be moved to the left-hand accessory drive pad. The standby alternator controller/regulator is mounted behind the interior panel near the pilot’s left leg.

For the Piper PA-32 series, the price of the standby alternator system is $3290. It can be installed on virtually all of the aircraft in the series; however, check B&C’s website to confirm that the serial number of your aircraft is included.

On Lycoming “dual mag” engines, the standby alternator is mounted on the hydraulic accessory drive pad. The standby mag will not fit turbocharged PA-32s equipped with the TIO-540-S1AD engine.

On engines with two separate mags, the standby alternator is mounted on the vacuum pump drive. If the vacuum pump is to be retained, it is relocated to the hydraulic accessory drive pad. Lycoming parts are required to complete that installation, are not included with the kit and must be purchased separately.

Because of the wide variety of installation requirements, we were unable to get an estimate of installation time other than the most basic starts at 10 hours and goes up from there.

The B&C website has installation instructions for its standby alternators that are mounted on the vacuum pump pad. For any installation that has a variation on that theme, the website directs the reader to call B&C. The site’s reference library did not include such things as the Airplane Flight Manual (AFM) Supplement, the STC or Instructions for Continued Airworthiness, as we would expect. We think a prospective buyer should be able to see those documents in the process of making a purchase decision.

We note in passing here that all of the materials we have seen on the B&C standby alternator system call for it to be turned on at engine start so that it can step in without pilot action if the primary alternator fails. Yet, during our research we were informed of a gear-up landing in a Beech Bonanza after the alternator failed and the battery went flat.

To our dismay, it turned out that the airplane had a B&C standby alternator system installed—yet the pilot had not turned it on at engine start. When the alternator failed the pilot also failed to activate the standby alternator (which has to be done while the battery still has sufficient charge to excite the standby alternator—normally not a problem). The pilot flew long enough to discharge the battery to the point that it would not extend the gear.

The pilot also failed to attempt to extend the gear manually.

We like backup systems, but they are only as good as the pilot flying the airplane.

Time was that alternators would make it about halfway to engine TBO. They’re a lot better now—at the FBO where I instruct the Plane Power alternator on one of the 172s just hit 4000 hours.

Nevertheless, maintenance technicians we spoke with urged regular examinations of alternators—at least during annual and 100-hour inspections—to keep small problems small.

For gear-driven or direct drive alternators, the manufacturer has specific inspection requirements because alternator failure can cause catastrophic engine failure. Gear-driven alternators have some sort of flexible coupling designed to slip or fail and protect the engine should the alternator lock up—inspect it per the manufacturer’s instructions.

For belt-driven alternators, inspection should include belt tension and alignment of the pulleys. Misalignment can cause accelerated belt wear and/or the belt to come off of the pulleys. The belt should be soft, flexible and free of nicks, cuts and significant wear. Believe it or not, over time, the belt will cause wear to the pulleys—check them as well. I was shown wear on a pulley of a multi-thousand-hour alternator last week.

Cracked alternator mounting brackets occur frequently enough to warrant a check each time the alternator is examined, according to the techs I spoke with.

Finally, the most common cause of charging system issues other than alternator failure is with connectors or wiring that has become worn or chafed—eyeball them well.

FREEDOM AVIATION

Lynchburg, Virginia-based Freedom Aviation (www.standbyalternator.com) offers a standby alternator kit for post Cessna shutdown Cessna 182Ts and 206Hs—normally aspirated and turbocharged. While the website states that the system is for G1000-equipped aircraft, Freedom’s avionics manager Jason Moorefield told us that it is approved for the pre-G1000 aircraft as well. The STC, available on the company’s very well-designed website, confirmed Moorefield’s statement.

Freedom’s standby alternator system is strikingly similar to that of B&C Specialty’s and uses a B&C-built 20-amp alternator. It mounts on an accessory pad on the Lycoming engine—Moorefield was the one who advised us to ensure that there’s a gear under the pad. The system has a voltage regulator and switches, circuit breakers and annunciator lights. As with the B&C system, the standby alternator is turned on at engine start. The system runs in the background and activates the standby alternator upon detecting the voltage drop associated with a primary alternator failure.

A flashing standby alternator light alerts the pilot to the need to reduce electrical load to below 20 amps.

The price for the kit is $4295. Moorefield told us that installation takes 10 to 15 hours with the 15 being for a shop’s first time and the 10 for subsequent installs.

We were impressed with Freedom Aviation’s website on its standby alternator. It explains the system clearly and provides the STC, AFM Supplement, Instructions for Continued Airworthiness, installation instructions and a detailed system drawing for download.

BASIC AIRCRAFT PRODUCTS

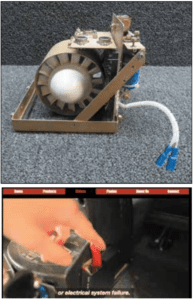

Basic Aircraft Products (www.basicaircraft.com) offers what we consider to be a pretty remarkable standby power source that it calls the Turbo Alternator. It is a 14- or 28-volt electric generator spun by a ram air turbine (RAT) that folds out of the airplane following alternator failure, provided the pilot pulls a cable that releases the RAT. Because it is a generator and not an alternator, it provides electricity even if the aircraft’s electrical system is completely dead.

Because of its capabilities, Basic Aircraft also offers a version of its Turbo Alternator for vintage aircraft that have no electrical system.

Company owner James Aarestad told us that power output of the Turbo Alternator depends on airspeed, but said that it’s normally about 15 volts. That’s enough to power basic equipment, in our opinion, to safely land after an alternator failure.

According to Aarestad, the Turbo Alternator is STC’d for the Beechcraft Bonanza line, Cessna 182, 206 and 210, Mooney M-20A-R, Piper PA-28 and -32.

Installation involves cutting a small hole in the skin of the aircraft fuselage or wing, sliding the unit in and securing it with 24 rivets. It can be wired to power the main electrical bus or the avionics bus. The cable that is pulled to deploy the RAT is run to a location where the pilot can reach it.

Aarestad told us that installation takes about eight hours and said that he noted that some buyers do the install during the annual inspection as it takes less time when the airplane is already opened up.

When we did the research for this article we noted that the website showed no pricing and said that the units were out of stock but should be shipping again in July 2022. We asked Aarestad what was going on. He told us that the designer of the Turbo Alternator and original owner of the company had passed away. Aarestad bought the company and is in the final stages of moving it from Georgia to Minnesota. He said that he hoped to begin shipping units in July 2022 and pricing will appear on the website.

We also discussed the relative lack of detailed information on the website such as the STC, installation instructions and AFM Supplement. Aarestad said that the previous owner of the company had done little marketing—hence the limited website—yet had sold 1200 Turbo Alternators to users around the world. He, Aarestad, remarked that he intended to provide more information on the website.

We’re aware that RATs have saved the day on military jets more than once and will be watching to see what happens as Basic Aircraft restarts production. We think this simple concept is a good way to arrange for electrical power backup in certain limited circumstances. If IFR, the need to reduce load to 15 amps might mean shutting down avionics that we’d like to have, and we don’t want to think about using a RAT in icing conditions; nevertheless, in our opinion, it is better than having to rely entirely on battery life when things go south.

CONCLUSION

The standby alternators offered by B&C Specialty and Freedom Aviation are long-proven technology that has even been embraced by OEMs. For the owner who flies serious IFR with any regularity, is concerned about battery life after an alternator failure and owns an aircraft for which there is an STC, we think a standby alternator is a good investment.

We are looking forward to seeing pricing of the Turbo Alternator, as it has the potential for providing backup electrical power on a budget.