Given the clinical-focused form factor and electrical power required of most oxygen concentrator systems we’ve looked at in the past, we all but dismissed most of them as impractical for use in small aircraft. Aithre—the company that’s been leading the charge with a wide variety of cockpit biometrics products—brings a new solution with the Altus Turbo Oxygen Maker.

Given the clinical-focused form factor and electrical power required of most oxygen concentrator systems we’ve looked at in the past, we all but dismissed most of them as impractical for use in small aircraft. Aithre—the company that’s been leading the charge with a wide variety of cockpit biometrics products—brings a new solution with the Altus Turbo Oxygen Maker.

This system is designed for permanent installation in a variety of GA airframes, with the capacity to supply enough pure breathing oxygen for a couple of users we’ll into the teens. Here’s a product overview.

The hardware

The Altus Turbo generates high purity continuous breathing oxygen using what’s called PSA, for Pressure Swing Adsorption. Self-contained within the unit is a piston compressor pump, zeolite consumable sieve beds and logic circuits. The Turbo (mounted in the tailcone or nosecone/avionics bay) intakes ambient air and outputs a minimum of 93 percent concentrated oxygen.

As a whole, the system includes the remote-mounted Turbo control unit, a panel-mounted O2 control button, cannula plugs and associated plumbing and electrical connections. As for power consumption, it’ll draw roughly 5 amps of current in a 14-volt electrical system, plus it has an onboard temperature control unit that cuts off the internal piston’s compression above 80 degrees C. There’s also internal fuse protection.

Worth mentioning is that the system can be supplemented by the company’s composite oxygen bottles as a safety layer. The optional backup line includes a red oxygen placard, checked panel cannula plug, plumbing and fittings for connecting to a remotely mounted Aithre oxygen bottle.

The lighted O2 push-button switch turns the system on and off, and oxygen is produced immediately upon activation of the switch. The dimmable O2 annunciator lamp stays on whenever the controller is functioning. The system also comes with two cannula plug-ins for the pilot and passenger.

At a glance these plugs look alike, but differ in that the passenger’s plug has an internal check valve. When it’s not in use, the passenger’s plug remains closed, diverting all flow of oxygen to the pilot’s cannula plug. When a passenger plugs in, the oxygen flow is split evenly between both plugs.

A single Turbo unit is authorized for one-person use at altitudes up to 18,000 and up to 15,000 feet for two users, though Aithre warns in its user guide that these absolute altitudes may be limited to lower based on a variety of biometric factors, including the user’s age and health/fitness.

The system is supplied with two platinum-cured silicone cannulas or the optional Aithre boom cannula. We looked at these and others in the April 2023 issue of Aviation Consumer.

There’s also the optional Illyrian II haptic safety sensor, which is used for continuous monitoring of blood oxygen, heart rate, cabin altitude and head movement, plus it provides outputs via user-configurable haptic vibrations. The data is also streamed to the Aithre Connect iOS app, to the Aithre Healthview panel display and to some Garmin, Dynon and Advanced Flight Systems panel avionics. Impressively, the Aithre biometric ecosystem seems to be growing every time we take a fresh look.

Operation, install, upkeep

Cabin oxygen systems should be straightforward to operate, especially for users new to the chore. For the Aithre Turbo, push the male terminal end of the cannula into the station’s plug-in port. Stick the tube into the end of the nostril and breathe normally. With the Altus Turbo, oxygen is delivered at 1.0 to 1.4 LPM unless there are two cannulas plugged in. As noted earlier, 50 percent of the O2 flow goes to each wearer.

The Altus Turbo automatically pairs and connects wirelessly to the Aithre Connect app, where the app outputs the current state of the O2 generator, plus onboard temperature and oxygen flow rate. In theory, you could connect up to three Turbo units to the app, and Aithre said some installations have been accomplished with multiple units to accommodate more than two users in the cabin.

Wiring is simple and requires connecting circuit-protected ship’s power (12 to 18 volts DC) to the Aithre Turbo control unit, plus a ground wire. The O2 button harness wires are simply cut and extended as needed to reach the place on the panel where the command buttons will be installed. The button installation requires cutting a 19-mm diameter hole and each cannula port requires a 13-mm diameter hole.

There is also an optional discrete fault output line that may be wired to an associated pin of select engine monitoring systems, including the experimental GRT EMS. The discrete output line provides a Low ground output in the event of a fault detected for altitude, temperature or flow rate of the O2 system.

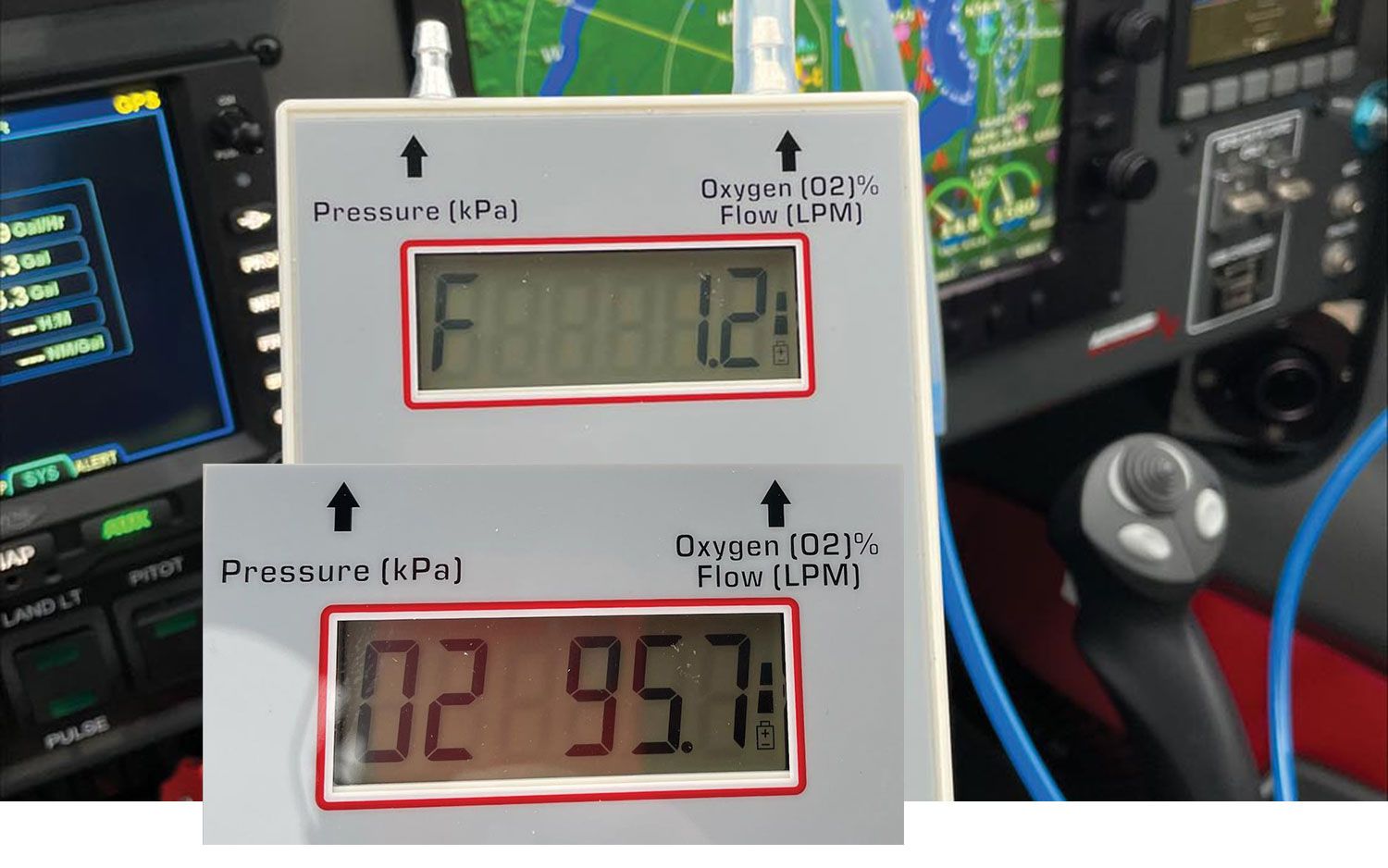

The Turbo control unit is secured in the airframe or avionics bay with a bracket/doubler plate and a hook bracket. You’ll want to install the small, 5-pound unit in a location that’s relatively easy to access. It will need to be removed every two years (or 2000 hours) for concentration/flow-rate testing, plus replacement of the flow control solenoids and controller circuitry. It also requires some space around the chassis for adequate air intake. Aithre sells a $395 digital oxygen concentrator tester.

Norsee approval

At press time, Aithre is working toward NORSEE (Non-Required Safety Enhancing Equipment) approval for installing the Altus Turbo in certified aircraft.

The Altus Turbo system is priced at $5355 and includes everything you’ll need for installation and for connecting two users.

Contact Orchard, Washington-based Aithre Aviation at 208-481-8310 and www.aithreaviation.com.