We consider engine oil analysis to be a valuable early warning system for certain types of engine problems. It allows an aircraft owner and maintenance technician to catch those problems before they become safety of flight items.

Because we feel it’s valuable, we wanted to know more about the labs that perform it. Do they give results consistent with each other? What is the turnaround time for a sample? Can they explain the results of a sample in a way that makes sense to an aircraft owner? Is there information on their website about the process and results clearly?

To answer those questions, we’ll give you a thumbnail sketch of oil analysis, then look at five of the most well-known labs—with what they offer and what they charge—and give our recommendations. We overnighted oil samples from two airplanes to five popular labs—receiving notification of the time of delivery—to monitor response time (you may need a fast response if you’re doing a prebuy on an airplane and need to see if there’s a deal-killer in the oil). We did not alert the labs that the samples were en route.

We’ll tell you up front that we put Blackstone in first place and AvLab second for their rapid response time, quality of their reports, knowledge of aircraft engines and information presented on their websites. We do not recommend any of the others.

The samples were from a Cessna T210L with 609 hours since major and a Piper Warrior with 2600 hours since new.

The Basics

All engines wear during normal operation—eventually they wear out. As they wear, they shed microscopic metal particles, too small to be caught in the oil filter—less than five microns in diameter. (A micron is one-millionth of a meter.) The quantity and type of particles produced as the engine is operating normally varies between engines, although there are commonalities between engine models.

Since wear is normal, analyzing the engine oil at every oil change provides a history of the type and quantity of metal particles shed by an engine, which means any significant change in the pattern is obvious and provides a warning that something is going wrong.

The value of oil analysis is trend monitoring. That means three things:

First, deciding to send in an oil sample for analysis only after you find pieces of metal with part numbers on them in the oil filter may not be of any value because the engine’s degeneration may be so bad that there aren’t any particles being shed small enough to make it past the filter and be analyzed.

Second, it’s using the system backward—without trend monitoring, it’s impossible to tell what led to the current condition and whether it’s a symptom of the problem or a result.

Finally, because the value of the system is trend monitoring and the values obtained from one lab may vary from another, it’s a good idea to stick with one lab.

Even though oil analysis is trend monitoring, we also recommend it on pre-buy examinations because it may turn up something that requires further evaluation or warns you to walk away from the airplane—that’s why we think a lab should be able to give you a result fast.

To have your oil analyzed the first step is to get a kit from one of the labs. Most sell the kits through the big aviation product suppliers, although one, Blackstone, sends out the kits for free and only charges your credit card after the analysis is complete (we like that a lot). The kits consist of a container, a form to be filled out and media for holding and shipping the sample.

Once you have the kit and are ready to take a sample, follow the procedure outlined in the kit. Fill out the form, providing the information requested such as engine model, time since overhaul, time since the last oil change and type of oil. Then ship the sample.

A container of a few ounces of oil is not hazmat. We noted that only Blackstone provides detailed information about this on its website. We think a lab’s website should have clear instructions on shipping—and dealing with a shipping rep that doesn’t know the rules.

Once the lab has received and analyzed your sample, it will provide you with a report, usually via email.

The Tests

We think a good lab should run four tests on your engine oil, spectral, insolubles, viscosity and flashpoint.

In its very basic form, oil analysis consists of spectral analysis—running a sample of your engine oil through a spectrometer. It determines the levels of various elements (metals) in parts per million, as we’ll as additives, in the oil. Most of the labs only did a spectral analysis. We found that the results of the spectral analysis to be within a few parts per million between the labs—within what we felt to be normal measuring variation.

The insolubles test measures the amount of abrasive solids in the oil—they are formed by oil oxidation and blow-by past the piston rings. It’s a basic sediment and water test performed in a centrifuge, and it is an indicator as to how we’ll the oil filter is doing. All oil has solids in it; the question is whether the amount is appropriate and whether the oil has oxidized.

The viscosity test measures the grade (thickness) of the oil. You tell the lab on the form you filled out what type of oil was used—the test determines whether the viscosity falls outside the range for that oil. If it does, it’s a heads-up that the oil has either been overheated or contaminated, usually with fuel.

Flash point is a test that measures the volatility of the oil—the temperature at which the vapors ignite. It should flash at a given temperature for a specific grade of oil. If it flashes at or above that temperature, the oil is not contaminated. If it flashes below, it’s contaminated; an indicator of a problem. The most common contamination is fuel due to a system issue or from normal priming.

The Labs

We obtained AvLab’s (www.avlab.com) Metal Check oil analysis kit through Aircraft Spruce. The price is $14.95 or $18.95 for the pre-paid “FedEx-Smart Post” shipping-paid version that can be dropped off at either the Post Office or Fed Ex and tracked to the Kenner, Louisiana, laboratory. AvLab sent us an email with its report the day it received our samples—faster than the advertised 24-48 hour turnaround it advertises. The report included levels of 12 elements with comparisons to the lab’s experience with average wear levels for the type of engine. Based on the results, the lab techs make comments and recommendations.

AvLab’s analysis only includes spectral analysis, not insolubles, flash point or viscosity, but it does include lead quantity in the spectral analysis, one indicator of blow-by. The report is color-coded to warn both of high absolute wear values as we’ll as major changes from previous tests. Previous reports are attached with the current one. The website contains good information on the source of wear metals and has a moderate level of information on the oil analysis process but is not easy to navigate.

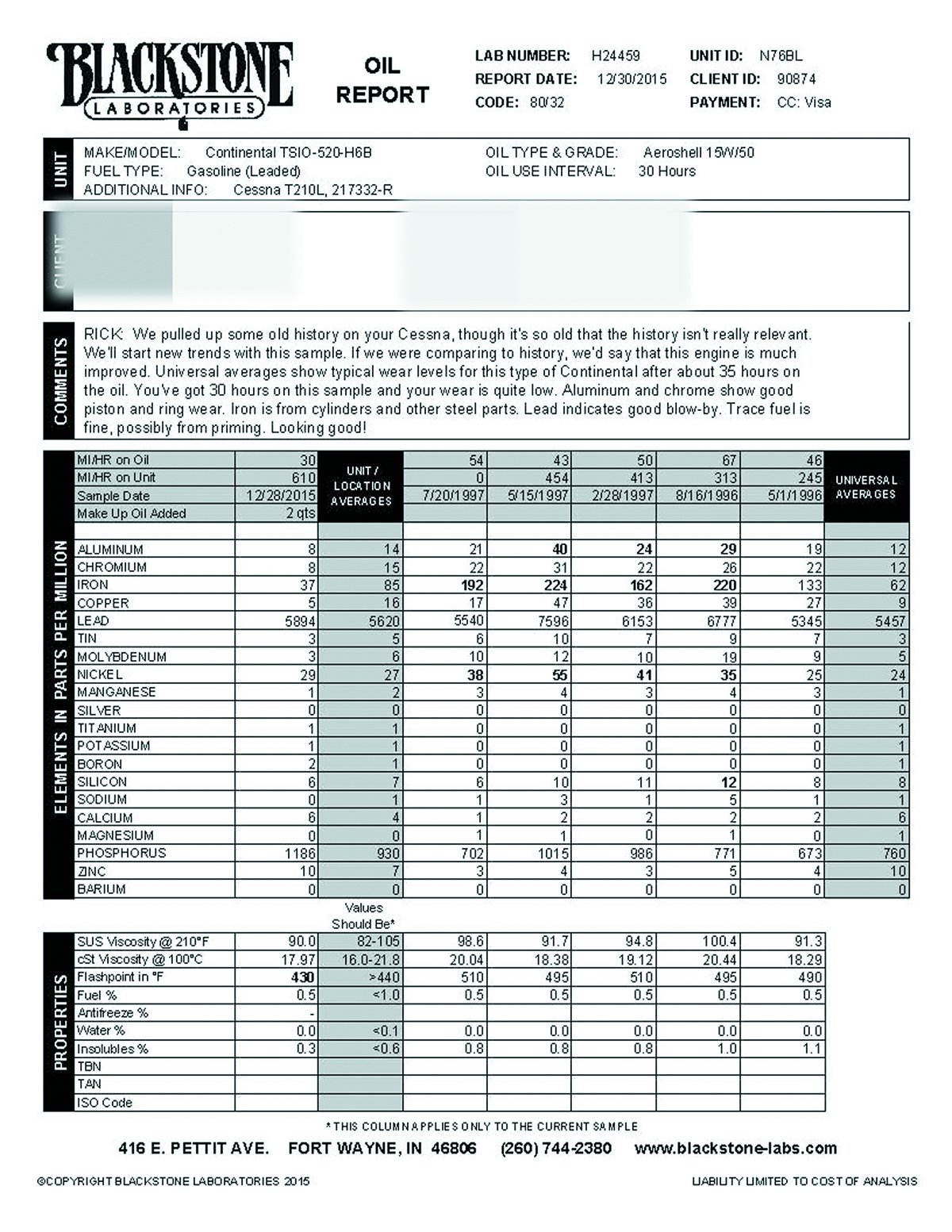

Based in Fort Wayne, Indiana, Blackstone Laboratories (www.blackstone-labs.com) sends out sample kits at no charge. You don’t pay until it emails you its report. Price for a standard analysis is $28 and it includes the four tests we feel are appropriate. The report is among the most complete and includes not only past results for fast trend monitoring, but also what it calls universal averages and unit/location averages for each metal. In addition, the easily navigated website provides information as to where each wear element/metal potentially came from in your engine, something we feel is valuable. It also provides videos on such things as taking a sample and understanding the report.

Above the hard data on Blackstone’s report there is a comment section in which the techs give their evaluation on the results. As with the comments section on AvLab’s report, coming from folks that have looked at a multitude of analysis results on a particular type of engine, we consider those comments to be of great value. In our experience they include potential sources for wear metal, evaluation of piston and ring wear considering the time on the engine, blow by and why there may be some fuel contamination (often normal from priming).

Blackstone says it will do its best to analyze and report on an oil sample it receives of a morning via overnight delivery. It did so with what we sent.

Oil Analyzers, Inc. (www.oaitesting.com) has several labs and encourages users to send its $24.60 ($34 postage paid) kit to the nearest. It advertises 24-hour turnaround on samples, although it sent us a notice it had received our samples the morning that UPS advised us they had been delivered, we had not received reports by the end of the next business day.

The company provides parts-per-million element information as do the other labs, however, it breaks those metals down into categories of wear, contamination, multi-source and additive—something we thought was useful. The presence of 24 metals are reported as we’ll as a breakdown by micron size of the particles. Oil Analyzers also reports on oil viscosity and oxidation. The company appears to target customers more in the motor vehicle and industrial equipment sector than it does in aviation—and the reports do not provide comments on engine wear. Due to a lack of orientation toward aircraft engines and failure to provide a report within two business days of receipt of a sample, we cannot recommend the company.

Lab One (www.laboneinc.com) began its life 30 years ago as an aviation oil analysis laboratory and expanded into other services. Based just outside of Phoenix, Arizona, it provides a 20-element oil analysis plus an oil viscosity report. Price for the kit, through Aircraft Spruce, is $12.95. We overnighted two kits with samples in one envelope and received confirmation from UPS the next morning that the package had been delivered. By the middle of the third business day, we had heard nothing from Lab One.

Adding to our dissatisfaction with the silence, we found that despite the company’s avowed aviation background, there was virtually no information on oil analysis in general or as it applies to aircraft engines on its website. The example reports provided were for diesel engines and engine coolant. While the price for Lab One’s service is attractive, we were not satisfied with the response time or the information we could receive on the website and cannot recommend Lab One.

We received the reports from Aviation Oil Analysis (throughALS Laboratory Group’s Tribology Division) (www.alsglobal.com) the morning of the third business day after it had received the samples. According to the advertising, “Upon receipt at the laboratory in Phoenix, AZ, the oil sample is analyzed and a full report is forwarded within 24 hours.”

The reports provided are rudimentary, sampling only seven elements. There is a basic color-coding regarding the overall condition. Past results are shown along with a graphic presentation that we liked. The diagnosis/recommendation provided for each case was terse: “All values appear normal.”

We obtained the kits for $12.95 each through Aircraft Spruce. As with the other kits, a form is included to provide information on the engine and oil. There was no form in one of the kits—and they serve as proof of purchase for the lab. Nevertheless, using the form we got, we provided the requested information on a sheet of paper and enclosed the Aircraft Spruce shipping label showing we had bought the kit—we’re pleased to report that it worked.

The website provides no information whatsoever about its aviation oil analysis. Overall, the company’s slow response, very basic report and absence of information on its website, led to the conclusion that we cannot recommend it.

Conclusion

Comparing oil analysis results indicated to us that the differences between spectral analysis results for the same oil sample—where parts per million are being measured—were so small that they can be chalked up to noise in the data and small differences within the same oil sample.

That led us to the conclusion that for aircraft engine oil analysis, what matters is the level of service provided and the ability of the level of aircraft engine expertise offered. Therefore, we recommend only two of the providers. We rank Blackstone first and AvLab a close second because of the quality of their reports, their response time and the fact that they know the general level of wear expected for engine types and thus make informed comments and recommendations based on the data and their experience. Blackstone got the nod because it does more involved testing, doesn’t charge for the service until it’s completed and has a more informative website.