by Joe Godfrey

What if there were a simple way to get more power from a piston aircraft engine while doubling the TBO? Potentially, there is. It doesnt come in a can, its done with the most basic chemicals and its been field tested by millions of engines for more than a century. Youd develop the same power but with CHTs about 200 degrees cooler with no worries of detonation or frying the engine with ham-handed leaning. You already have all this in the car you drove to the airport. Its called liquid cooling.

Liquid-cooled engines have been part of aviations history from day one. They enjoyed success in World War II, notably in the Merlin-powered P-51 Mustang and Supermarine Spitfire and the famed P-38 Lightning. When the military-especially the Navy-tilted toward air-cooled radials, longevity and economy werent priorities and jets soon eclipsed pistons, anyway.

But the allure of liquid cooling remains, promising better fuel economy, lower maintenance costs and even a shot at a 5000-hour TBO. Bob Atkins, the President of Liquid Cooled Air Power, a California engine development shop, thinks its possible. He and his colleagues have engineered parts for NASCAR, NHRA, Formula 1 and offshore racing where technology continues to improve performance and reliability, something lacking in the 60 year-old design of an air-cooled aircraft engine.

Atkins idea of change is as simple as it is bold: hed like to develop a new watercooled horizontally opposed aircraft engine, specifically the equivalent of Lycomings four- and six-bangers. It would be a nearly a bolt-on conversion.

A Decade of Work

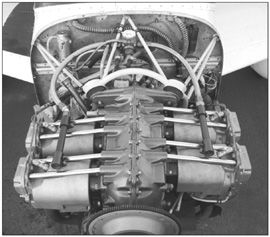

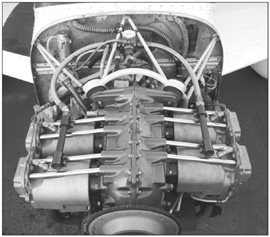

Atkins concept first hit paper in 1993, the tooling came four years later, and the first engine-an IO-360 with bolt-on water jacketed cylinders-ran on the dyno in March, 2001, where it generated 195 horsepower at 2700 RPM. Later that year, Atkins put his PA-28-180 into experimental status and flew it with the liquid-cooled system. After several iterations of hose routing, cylinder shape and size and more iterations of radiator design and placement, Atkins was ready to pursue an STC for hanging new jugs on a Lyc IO-360.

We examined Part 33 and we thought wed be facing a well-defined set of regulations, Atkins says, and we could plan and budget for those requirements. Atkins reasoned that because the mod didnt involve touching the internal moving parts of the engine-the water pump was powered from the standard Lycoming accessory case-an STC made sense. A meeting with the Long Beach, California Aircraft Certification Office seemed promising.

But by the time his project found its way to the FAAs Engine and Propeller Directorate in New England, the STC idea was dead. The FAA considered an engine with a liquid-cooled mod to be a new engine. Because Atkins and his partners would now have to go through the time and expense of certifying a new engine, they decided they might as we’ll build a new engine.So the team took a fresh look at combustion chamber design, valve and valve seat design, shape and flow of intake and exhaust ports, spark plug placement, FADEC ignition, gapless rings and muffler technology.

They also stared over the horizon at what will happen to thousands of engines when leaded fuel disappears. Atkins believes that because only one company-Englands Octel Corp.-still makes tetraethyl lead, the world is one explosion away from [avgas] going away forever. Further, Atkins is convinced that air-cooled engines cant run practically on unleaded fuel and will be rendered obsolete when avgas eventually vanishes. (The designers of FADEC systems intended to allow aircraft engines to run on lower octane fuel would argue that point.)

If the STC process is a hurdle, the engine certification process is a high jump. Atkins says, The FAA has always been concerned with engine reliability. Now theyre also concerning themselves with durability, too. The regs for engine certification explain the tests you have to do, then add any other testing as required by the Administrator… we have to run the engine at 200 hours under maximum continuous power, which is a test Lycoming didnt have to pass when it certified the IO-360.

Now, the goal of Liquid Cooled is to design and build a new liquid-cooled piston engine with a TBO of 5000 hours. Most engine wear is in the cylinders and most of that is due to heat. Too much heat, not enough heat, uneven heat distribution, differential heating and cooling of multiple metals…its a heat nightmare. A traditional solution has been to cool the cylinders with surplus fuel. Thats less appealing as avgas tops $4 a gallon and it still doesnt solve all the heat problems. Liquid cooling seems to address these issues directly, although that doesnt mean it will pan out to be either the best engineering or marketing solution.

A New Paradigm

Atkins and his team plan to use a kidney-bean shaped squish design in the combustion chamber with the spark plugs closer together to lower detonation margins. Theyll use nickel-carbide barrels because it provides a better oil surface than chrome and the barrels don’t need to be nitrided because they should never get hot enough to require it.

The engineers also plan to ramp the intake and exhaust ports because their dyno tests show an area of turbulence right in front of the valves. Our new cylinder design handles 330 cubic feet per minute. More air means more power and our intake is now exceeding what the standard induction system can give us. We can make more power because we can bring the temperature down. In our engine, the valve face temperatures are under 400 degrees F and the seat surfaces are under 300 degrees F and thats what you need to cool an exhaust valve, a good Delta T between the valve and the seat.

He details other plans for the new engine. we’ll probably tighten the piston clearances by making the bore smaller, because in an air-cooled engine, the pistons slap around a lot when theyre not at full power. We don’t ever get them that hot, so wed rather have a tighter fit so the pistons wear better, Atkins says. In place of magnetos, the new engine will have a closed-loop FADEC with knock sensing , feedback for mixture control and oxygen sensors similar to an automotive engine. Compression ratio will be a lofty 12-to-1.

Lower operating temps should mean no coked oil on valve covers, cylinder walls or exhaust valve stems or seats. They also plan to use gapless rings, which reduce blowby while producing more power and keeping moisture out of the oil.

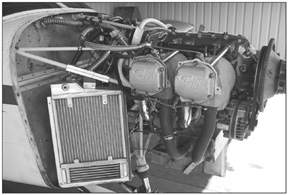

The biggest challenge in adapting an aircraft for liquid cooling is finding a place for the radiator. In automobiles, front and center works like a charm, right about where the prop sits on your airplane. In Atkins Cherokee, the radiator found a home between the engine and the firewall, and air is ducted from a port in the cowl. The opening is a bit bigger than the old port for the air filter, but the trade-off is the top half of the cowl can be sealed.

The radiator is the ninth iteration, with the design developed through research in auto racing, then fortified to withstand the higher vibration environment in an airplane. Racing experience shows that a small volume of air at relatively low speed and a high pressure differential at the radiator surface is the most aerodynamically efficient way to reduce cooling drag.That also allows a smaller air inlet and the air carries off more heat. A more efficient radiator means better cooling on the ground, too. Another bonus, claims Atkins: you can toss your CO detector, because your cabin heat will come from a radiator-based heat exchanger, not the exhaust system.

Coolant moves through high-pressure hoses with AN fittings, not hose clamps, more technology borrowed from auto and marine racing. The installation also includes a small reservoir tank and a pressure cap, just like the one on your car.

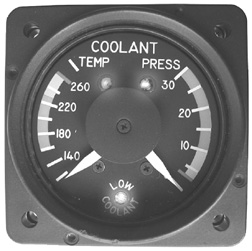

Pilots always check the oil level as part of the pre-flight inspection on an air-cooled engine, because oil and air are the cooling system. So it might surprise you to hear that a visual check of the coolant level isn’t part of the pre-flight on a liquid cooled engine. In fact, its not recommended, because opening the pressure cap introduces air into the system. But monitoring the coolant level is critical so part of the installation is a purpose-made panel-mounted gauge to monitor coolant level, temperature and pressure. Ideal coolant pressure is 20 PSI measured between the inlet and outlet side of the pump. Ideal coolant temperature is 200 degrees F.

The coolant concerns fall into three categories. The capacity of the cooling system is just under 3 gallons and a steady yellow low-coolant light comes on after a loss of about 8 ounces. If youre on the ground, you shut down and add coolant. If youre in the air when the low coolant light comes on, but pressure and temperature are still OK, plan to top off next time you land. Nothing urgent. The yellow light blinks to indicate the second concern-a serious leak where steam is building up and the pressure cap is starting to vent. If pressure and temperature are still OK, its time to throttle back to conserve coolant and look for a place to land. A blinking red light-never a welcome sight in an airplane-indicates air in the system, possibly a failed hose, requiring immediate landing. The coolant sensing computer is also designed to send its data to a multifunction display.

Since the goal of leaving the crankcase intact no longer applies, Liquid Cooled redesigned the water pump. It still runs from the governor pad, but now has its own gear assembly with a shear pin, so a water pump seizure wont take out the entire engine. In the event of a catastrophic pump failure, youd throttle back to reduce heat and land. In failed pump tests on the dyno, the engine ran at full power for 15 minutes and CHTs never got above 300 degrees F. An additional 15 minutes of run time elevated the CHTs to 350 degrees F. Atkins says the pump is designed to have a 5000-hour life and should easily last the life on the engine.

Other maintenance items include changing the coolant every two years or 500 hours and changing the thermostat, a $10 part, every 500 hours. The engineers thought ahead-the thermostat sits at the high point in the system so it can be changed without draining the system. Because the test airplane is based in Southern California, its running on water only. Its the worst case scenario for corrosion and boilover protection, but the theory is that if it survives the water-only test, then running the planned 50/50 mix of water and antifreeze will add additional safety margin.

Weight, Economics

Heres how the weight and CG numbers pencil out. The radiator and plumbing weighs about 25 pounds. Add another 24 pounds for three gallons of water, then subtract about 20 pounds when you eliminate cooling baffles and reshape the cowl and its about a net 20-pound gain in empty weight. On the Cherokee, the CG moves 1/8th inch forward, because the added weight is just forward of the firewall, not out by the prop.

And how about the dollars? The original goal-the STC mod for a Lycoming IO-360-would have cost about $16,000, including the coolant sensing computer.The new goal is to deliver a liquid-cooled engine incorporating the new cylinder head design, gapless rings and more horsepower for under $30,000.

If youre flying an Arrow with a first run engine at TBO, youre staring at $30,000 for a new Lycoming engine or between $16,000 and $20,000 all-in for an overhaul. Call it $16 per operating hour for the new engine and between $8 and $11 per hour for the overhaul, assuming you make Lycomings TBO of 2000 hours, which seems likely.

Factor in the cost of the conversion in a certified airplane-Atkins believes its comparable to a routine R&R but we think if the STC is done right it will cost more-and the liquid-cooled mod is economical if certain conditions are met. First, it would have to deliver service somewhat beyond the Lycomings 2000-hour TBO, if not the entire 5000 hours. Second, the engine will have to deliver on the claimed fuel economy, durability and, eventually, ability to burn unleaded fuel. If the engine does make these numbers, the required reserve costs work out to about $6 an hour, which we consider compelling economics.

Conclusion

Although we think liquid cooling is a terrific idea and were happy to see Liquid Cooled Air Power pursuing it, the obstacles to success are huge, as much economic and regulatory as technical. The historical performance of watercooled powerplants in light aircraft hasnt impressed the market.Theyve proven expensive, somewhat complex and, thus far, havent been sufficiently better than air-cooled engines to make them competitive. Rotaxs watercooled 912 had a shorter TBO and poorer fuel specifics than the air-cooled IO-240B Diamond chose to replace it.

Second, bringing an STC to market is difficult enough but worrying a clean-sheet engine design through the FAA certification mill is akin to reinventing the wheel. It will take enormous time and money and many companies have run out of both without getting close to certification. In that regard, we like the fact that Liquid Cooled will market engines into the experimental market first, then consider certification later. For experimentals Liquid Cooled expects to be shipping conversion kits for IO-360s and IO-540s by the summer, maybe sooner. Theyre hoping for certification of the new engine design sometime in 2006 but realistically, we think it will take much longer than that.

As with the success of FADEC technology, the fate of liquid cooling may be tied largely to the future of avgas. If, as some predict, avgas goes out with a flash and a bang, there will be a frenzied scramble for replacement technology, a development that could work in favor of Liquid Cooleds engine design.

Contact – Liquid Cooled Airpower, 310-802-1255, www.cooljugs.com.

Also With This Article

“Checklist”

“Performance Claims”

“Nice Idea, But Mixed Results Thus Far”

-Joe Godfrey is a pilot and freelance writer. He lives in Leucadia, California.