Cessna’s first post-World War II twin-engine airplane, the venerable 310 is a logical consideration for anyone looking to step into the world of piston twins. While it doesn’t come without some quirks, it’s roomy, stable and has cruise speeds that top 200 MPH.

But before even considering any vintage of the 310 (it was produced between 1954 and 1981), any buyer needs to understand the airplane is complicated, particularly from a maintenance standpoint and even more so for one that hasn’t been properly cared for. It can also be a demanding airplane to fly, especially for pilots who aren’t properly trained.

Still, when maintenance and proficiency come together, a 310 could be among the most satisfying light twins to own. Better yet, our scan of the current market reveals a model line that has fairly strong resale value-especially for late-model airplanes.

Model History

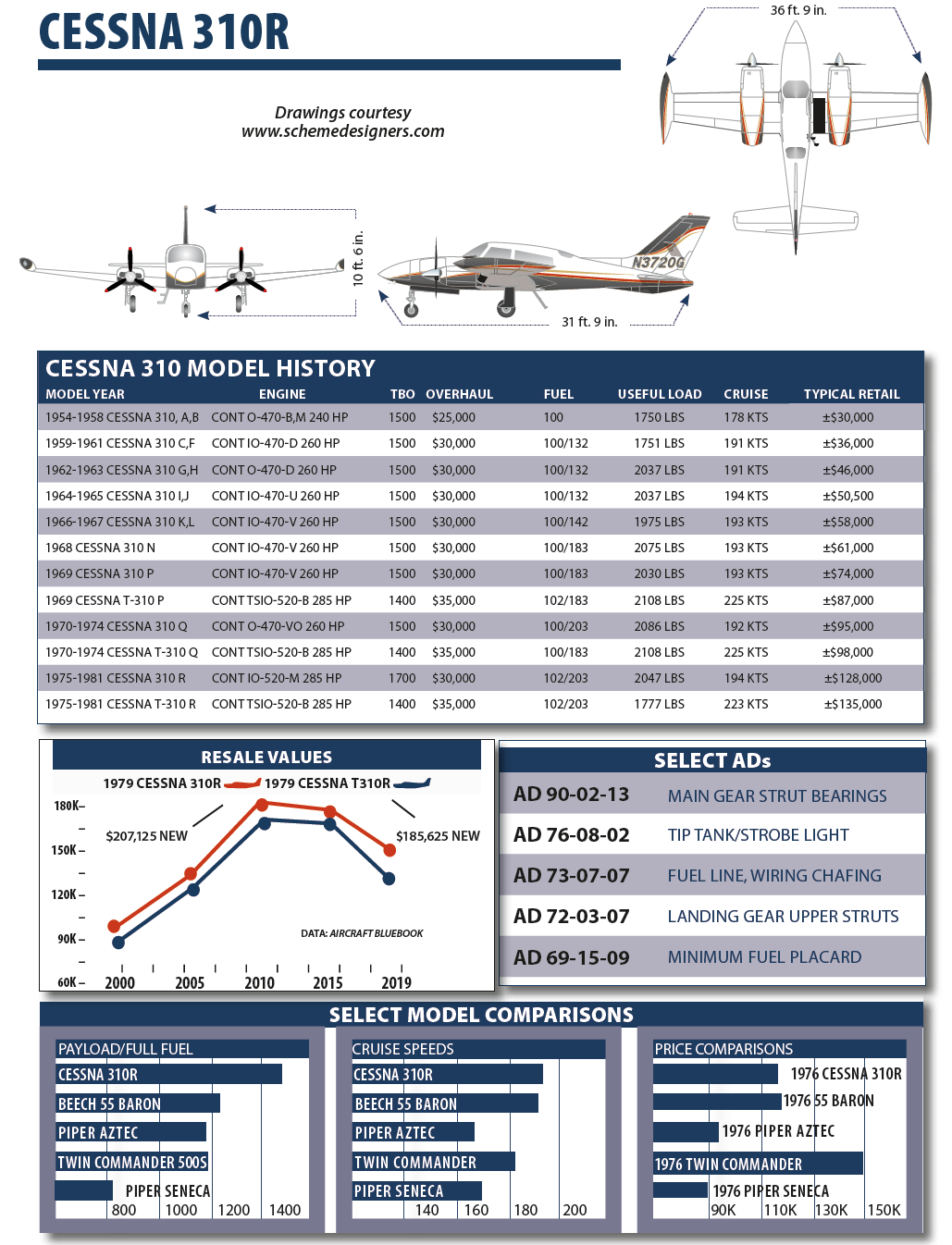

Cessna introduced the 310 in 1954,finding a niche between Piper’s original, relatively underpoweredPA-23 Apache, introduced a year earlier, and Beech’s Twin Bonanza, which went out of production a few years later. It competed most directly against the Aero Commander 520, but that model was discontinued the same year. The 310 was Cessna’s first all-metal, modern twin-replacing the prewar T-50/AT-17 “Bamboo Bomber”-and was clearly focused on business transportation. It foreshadowed the company’s subsequent products and helped usher in its future growth.

And its featured presence in the 1950/60s television drama “Sky King” didn’t hurt anything. Its namesake hero, played by Kirby Grant, upgraded to a 310B shortly after that model became available. Named “Songbird,” the airplane (several were actually used during the show’s production) was as much a star of the series as its actors, perhaps becoming the main reason for the show’s popularity on Saturday mornings throughout the 1960s.

Cessna’s aggressive pursuit of the business market manifested itself in not only the 310’s looks, but also its refinement: Many production years saw a new model designation. Cessna brought out the 310B in 1958, the 310C in 1959 and the 310D in 1960, eventually getting to the 310R in 1975 (with a few gaps) before ending production in 1981.

The first 310s came with 240-HP Continental O-470-B engines. From the beginning, a sleek, powerful appearance was a design goal, with tight cowlings and streamlining at the nose and tip tanks (at least by the standards of the day). Split wing flaps eliminated the need for external brackets or tracks and their drag.

Distinguishing features of the early models are multiple aft side windows, a straight tail and non-canted “tuna tanks,” named for their shape. When the 310B came out in 1958, it brought with it a 100-pound boost in gross weight.

For the next year’s 310C, an engine change and gross weight bump occurred with the fuel-injected, 260-HP Continental IO-470D. The TBO was 1500 hours, same as with the earlier powerplants.

For the 1960 310D, Cessna swept the tail, as it did across its fleet.

The next significant change was in 1962, with the 310G. Cessna introduced canted “Stabila-Tip” tanks, said to be more aerodynamically efficient than the old design. The original non-canted and bladder-equipped tip tanks also had a fuel pickup problem; an airworthiness directive mandated a hefty increase in unusable fuel. This 310, with bladderless all-metal canted tanks, swept fin and short nose, is often said to be one of the most attractive light twins ever built.

Cessna didn’t stop there. Cabin size was increased, along with gross weight. What started as a five-place twin became a six-placer with 1963’s 310H. By next year’s 310I, wing lockers and auxiliary tanks became options, as did three-bladed props. One significant difference was the switch from the corrosion-prone overwing exhaust design to an improved underwing arrangement on the 310I. An engine change accompanied the modifications, to the IO-470-U, still of 260 HP and still with a 1500-hour TBO. Another engine change, to the IO-470-V, occurred in 1966 (310K), along with extended, one-piece aft windows on each fuselage side.

In 1969, Cessna consolidated its model line, offering a turbocharged variant of the 310 alongside the normally aspirated 310P. The T310P came with 285-HP Continental TSIO-520-B engines (1400-hour TBO), three-blade props and a 5400-pound gross weight, compared to the normally aspirated 310P’s 260-HP IO-470V Continentals, optional three-blade props and 5200-pound gross.

From 1970-74, Cessna stuck with the 310Q and T310Q, despite bumping gross weight on the 1972 T310Q to 5500 pounds (5300 for the non-turbo version) and changing to wrap-around “Omnivision” windows by adding a pair of small panes at the top of the aft cabin.

In 1975, the 310R II and T310R II sported one of the biggest changes since the type’s tail was swept: an extended nose. The proboscis grew 32 inches, housing a sizable baggage compartment. The normally aspirated version also got 285-HP Continental IO-520-M engines (1700-hour TBO) and another 200 pounds were added to the gross weight-bringing it to 5500 for both the turbo and non-turbo versions-along with improved landing gear.

The 310R marked the airplane’s final configuration, which continued until the line was closed down in 1981. All told, some 5700 copies of the 310 were manufactured, not including its various military versions. Unsurprisingly, the 310Rs are the most numerous, followed closely by the 310Q, a result of sticking with one model for several years.

Performance, Handling

An old saying about piston twins-they have two engines because they need two engines-refers to what’s necessary to obtain their performance and their handling when one engine fails. Both are strong points of the 310, especially the turbocharged versions. Early models feature high-speed cruise in the neighborhood of 175 knots while later ones will top out at around 190.

The turbo’d models can present 225 knots at all-out max cruise, but the fuel burn will be breathtaking. Reduced power settings get 175 knots on later, non-turbocharged models.

Engine-out performance is better than average, with normally aspirated 310s achieving a single-engine service ceiling of just under 7000 feet to 7500 feet, depending on model. Turbos see single-engine service ceilings of 17,000-18,000 feet and climb rates from around 330 to 440 FPM, depending on model and turbocharging.

Figure cruise fuel between 20 GPH for an early, non-turbocharged 310 at economy settings up to 35 or more when flogging a big-bore turbo. Join the Church of the Lean-of-Peak and shave that down to around 28 GPH. Airspeed suffers, of course. Double those numbers, at least at the low end, for takeoff and initial climb.

Speaking of climb, the non-turbocharged models do fine in the low teens and turbo models in the high teens, although their service ceilings can be as high as 28,200 feet (T310Q). They’re happiest in the mid-to-high teens: One owner told us, “At FL250 (the T310R) performs like a very expensive Skylane.”

Book short-field performance is surprisingly good, especially for the airplane’s weight: Landing over a 50-foot obstacle in a 310R will consume 1790 feet, compared to a Model 58 Baron’s 2498. Taking off over that same obstacle will require 1700 feet in the 310, while a Baron needs 2100 feet. As you’d expect, pilots and owners treat the book numbers with a grain of salt, reporting poorer real-world numbers.

Once airborne, however, 310s provide an extremely stable platform. The only fly in the ointment is the type’s tendency to Dutch roll, especially in turbulence and in an inexperienced pilot’s hands, caused in part by the high rotational inertia of fuel in the tip tanks. Experienced owners tell us Dutch rolls are easily dampened with proper technique.

As clean and powerful as the 310 appears, it can get draggy on approach. Relatively large props blank out much of the wing and split flaps produce much more drag than lift.

This can be a “good thing,” since the clean airframe can be difficult to slow down until the first notch of flaps is deployed.

Early models came with an approach-flap extension speed of 140 knots, with full deployment available at 120. The 310K bumped the approach-flap speed to 155 knots or so. Subsequent models through early 310Rs are placarded for 160 knots approach-flap extension and 140 knots for full flaps. Drop two knots from those numbers for late 310Rs.

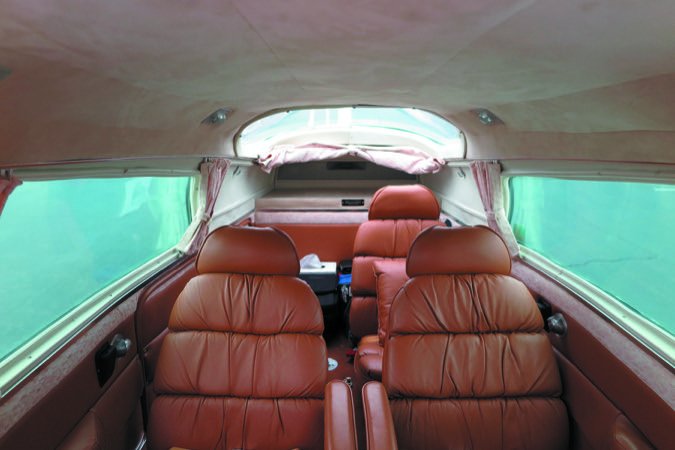

Cabin Loading

For the early models, up through the 310G, interior space is about average for baggage, which means having to stow some items under and between seats, or at passengers’ knees. Beginning with the stretched cabin of the 1963 310H, more baggage space was opened up. Wing lockers, whether installed at the factory beginning with the 310I or in the field, can help, as does the 310R’s nose baggage compartment. Removing the aft row from the six-seat airplanes (quick disconnect seats were optional on later models) can help, too.

Weight and balance must be watched closely. The first nose extension-a small one-occurred with the 310K. But by the 310I, cubic feet available began to exceed the airplane’s weight-lifting capability. No longer could a pilot “cube-out” a 310 before overgrossing it and it could be loaded out of forward CG. Adding lots of avionics and other options to the typical model only compounds the problem by upping the empty weight. One solution is STC’d vortex generators that can boost max gross by 100 pounds or more. That said, you can find late-model 310s with close to 2000 pounds of useful load.

The 310’s full-fuel payload varies depending upon the model, equipment and fuel tank arrangement. Total usable fuel capacity can be 100, 132, 142, 183 or 203 gallons-from 600 to 1218 pounds of fuel. Full-fuel payload in a lightly equipped 310C with auxiliary tanks might exceed 700 pounds, while it could be as low as 400 pounds in a 310R. Other loading and operating considerations, like maximum landing weight and zero fuel weight, were introduced with later models.

Fuel System

The 310’s fuel system on airplanes with all the optional tanks is more complicated than most. It also has a number of idiosyncrasies. The complications start with nomenclature. Ask a line person where the main tanks are on a given airplane, and they’ll likely point to the wing. With the 310, they’d be wrong. Early models only came with the 50-gallon-per-side tip tanks. As there were no tanks in the wings at all, those were main tanks. As time went on, horsepower increased and so did demands for fuel. First came 20-gallon wing-mounted bladders, followed by an additional 11.5-gallon bladder, for 31.5 gallons in each wing. Then came 20-gallon tanks in the wing lockers. In a 310R, as much as 203 gallons can be available.

If the pilot has the mains topped and takes off without checking the fuel actually went into the right spot you can guess what might come next. That’s not the only tricky thing about the 310’s fuel system. A fully equipped 310 with wing locker tanks can have up to 10 fuel drain points and eight fuel pumps. Connecting all this is a relatively complex (when compared to other piston twins) plumbing system. There’s no separate gauge for each tank, though the gauge does switch automatically to read the tank being used (but not the wing locker tanks, which have no fuel level senders). The pilot can read the tanks not in use by toggling a switch. Confused yet?

Fuel feeds to the engines from either the mains or the aux tanks (but not from the wing locker tanks, if installed). Presuming the mains were full at takeoff, at least an hour’s fuel has to be burned off if the airplane has 20-gallon aux tanks (90 minutes for 30-gallon aux tanks) because excess fuel is pumped back to the mains. If there isn’t room for it in the mains, it goes overboard.

The mains also are the receptacle for the contents of the wing locker tanks and there has to be room for transferred fuel. The pilot should wait until there’s 180 pounds or less in the mains before pumping from the locker tanks. The aux tanks feed directly to their respective engine, and the only pump serving them is engine-driven. In the event that pump or engine fails, the aux tank on that side could hold 30 gallons of dead weight; there’s no crossfeed from the aux tanks to the opposite engine. Hopefully you’ll never discover this factoid the hard way, but those big tip tanks were originally designed as a safety feature, to get fuel as far from the cabin as possible.

Early on, a prototype landed gear-up and the tip tanks separated just as they were designed to do, with no post-crash fire.

The good news? The 310 is not unduly prone to fuel mismanagement accidents, so despite the system’s apparent complexity, pilots seem to have little trouble dealing with it. All those tanks can carry a great deal of fuel, making six- or seven-hour endurance possible in later models. Early models go for four to five.

Landing Gear

The other 310 system usually getting lots of attention is the landing gear. It’s relatively tall and, as a result, often thought to be more delicate than with other airplanes. Also, all that fuel hanging out on the wingtips tends to create high side loads.

As with so many other general aviation landing-gear systems, one of the keys is finding a technician familiar with and knowledgeable about it. The 310’s gear system includes a number of components requiring proper rigging during regular inspections. Done properly, trouble can be avoided, but failure to treat the gear with respect increases the odds of failure dramatically.

People with keen familiarity with the 310 tell us of three weak points in the gear system. The nosegear idler bellcrank, located under the pilot’s feet, is probably the worst since its failure-always at retraction, and always loudly-means two prop and two engine teardowns.

The main-gear torque tubes and inner landing-gear door actuator bellcrank are the other two. If the torque tube fails, it does so during the retraction sequence, leaving the associated main gear down and locked. Extend the rest of the gear and land. If the inner landing gear door actuator bellcrank fails, the inner gear door hangs in the breeze.

Later-model 310s have heavier main gear torque tubes and side brace support brackets. Cessna has a kit available to retrofit earlier airplanes.

Another gear issue that deserves mention is the brakes. Early models had problematic Goodyears. Many were retrofitted with the later, and better, Clevelands. Still, the 310 is large and heavy enough that brake performance can be marginal. Nail the speeds on landing.

Maintenance

A scan of FAA Service Difficulty Reports going back several years dredged up numerous entries, underscoring the 310 fleet’s age. Items garnering our attention included a cracked rear mount bulkhead in a right main (tip) fuel tank, sheared horizontal stabilizer attach bolts and a brake disc cracked where its manufacturer’s name was stamped. But the single system receiving the most entries was, by far, the landing gear.

This in itself reinforces the need for a 310 expert to conduct any pre-purchase inspection and for a shop with intimate familiarity to do your ongoing maintenance. That said, most retractable-gear airplanes originally designed in the 1950s likely will require similar attention and expertise.

Market Prices

When considering an airplane in production for almost 30 years, and with so many variants, it shouldn’t come as a surprise 310 prices vary widely. An early “straight” 310 averages only $30,000 or so in today’s market, rising to $148,000 for a 1981 turbocharged T310R, per the winter 2019 Aircraft Bluebook. Between those extremes, there’s no

real “spike.” Instead, each successive model sees a modest increment in price. The biggest single gap is between the 310Q and 310R-the 1974 310Q averages around $100,000, while the 1975 310R has a typical retail price around $110,000, according to the Bluebook. The gap for the turbo models is similar. With those “starting” prices, there’s no question the 310 can be a good bargain. On the other hand, keep in mind that ones with low-time engines, modern avionics and nice paint and interior work sell for a lot more. We spotted an air conditioning-equipped 1978 310R on the market for $219,000.

Mods, Type Clubs

Modifications for the various 310 models run the gamut, from the usual avionics upgrades to improved cabin heaters, auxiliary fuel tanks in the nacelles and cabin, and electrically de-iced props. Other mods include vortex generators (VGs), something we highly recommend for all twins when available. They often come with gross-weight increases, as they can reduce critical speeds. Check Micro AeroDynamics at www.microaero.com, 800-677-2370.PowerPac Spoilers (www.powerpacspoilers.com, 800-544-0169), as their name implies, offers a spoiler kit for the 310R; it requires the Micro AeroDynamics VG kit.

Colemill STC engine and prop upgrades are available from Mike Jones Aircraft (www.mikejonesaircraft.com, 615-896-5678) for the 310F through R, and may come with gross-weight increases. A choice of IO-520s or IO-550s is offered; prices and performance gains depend on aircraft model and options selected.

Also, RAM Aircraft (www.ramaircraft.com, 254-752- 8381) offers engine upgrades for the 310R, but mainly focuses on upgrading powerplants for the turbocharged 310 models.

All piston-powered twin Cessnas have their own support organization in the form of The Twin Cessna Flyer (www.twincessna.org, 877-977-3246), and the group is a valuable source of knowledge for all things related to Cessna twins.

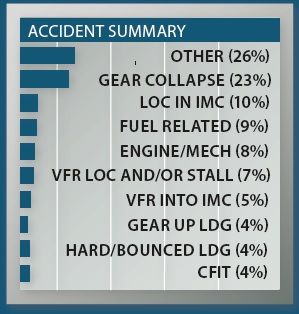

With a fuel system frequently described as complex or challenging, we were especially interested in the fuel-related accident numbers. We found only eight-about half what we’ve observed for twins with “simpler” fuel systems such as the Beech Baron and Cessna 337. Of the eight, one was caused by fuel contamination that affected only one engine, one pilot positioned a fuel selector valve between the “main” and “aux” positions and the remainder either mismanaged the fuel aboard or didn’t bother carrying enough.

We can’t help but wonder if having a fuel system that requires some initial study doesn’t cause pilots to approach fuel management more carefully than in other twins.

We were concerned about the high number of gear collapse accidents-23. There were also two events in which the pilot was unable to extend the gear because of a mechanical failure. That’s a lot. We think that it’s because of a loss of institutional memory about the demands of rigging the 310 gear. It’s not hard, it just has to be done right-by the book. There are no shortcuts.

Would-be 310 owners need to fully understand that it generally takes two techs, who know what they are doing, some eight hours to rig that electromechanical gear. They have to start in the middle of the airplane and work progressively outward toward all three gear legs-and they have to do it per Cessna’s manual, adjusting tensions and getting rid of parts that are out of tolerance. Plus, you cannot rig just one gear leg-it’s a recipe for a gear collapse or jam.

Pilots should also be aware that if the nosegear strut is bottomed-out, it’s a no-go item. On retraction, the nosegear will jam in the we’ll and will not extend.

In our opinion, the 310 gear works well, but it does not tolerate a casual attitude toward maintenance nor any shortcuts.

We saw that there were no injuries in any of the landing gear-related accidents, although we did see one seriously stupid pilot trick. Our hero faced an emergency: The gear would not extend. He decided to intentionally create another emergency, one we doubt he’d practiced for-a double engine failure. He shut down and feathered both engines-and crashed short of the runway. Doh.

We were impressed that there were only two runway loss of control (RLOC) accidents-and one of those was on an icy runway. With its wide-track gear, the 310 has excellent ground handling.

Sadly, we saw how important it is to be most cautious on a first flight out of maintenance. One pilot’s preflight didn’t catch that the elevators had been rigged backward. He crashed fatally, shortly after takeoff.

Following major work on one engine, one pilot decided to ferry his 310 to another airport gear down because the needed repairs to the gear hadn’t been completed. You got it, the engine work was done improperly and it blew out all of its oil. Even with the prop feathered, a 310 won’t hold altitude on one engine with the gear down.

Owner Comments

I spent nine months looking at Cessna 310s as they are one of the few aircraft that actually meet my needs (and are in my price range). I flew a 310R back in the late 1970s for my first flying job, and I remembered what a wonderful-flying airplane it was.

I purchased a 1977 310R last April and have put close to 100 hours on it so far. I am absolutely thrilled with the airplane as it does everything it was designed for both economically and efficiently. I operate off of a 3000-foot private grass strip and the vortex generators make a huge difference. In fact, I would never want to fly another twin without VGs.

I flight plan for 190 knots, burning 27 GPH rich of peak. With the addition of GAMIs and a new engine monitor in the near future, I will certainly run LOP, as I have a fair amount of experience doing that in my other aircraft.

As an A&P/IA, my direct operating cost is probably somewhat skewed. But The Twin Cessna Flyers’s association claims an average of around $347 per hour. I would say mine is closer to half of that. And my insurance rates are what I would consider to be rock bottom at $2350 per year, with full hull value set at $100,000. I do have a fair amount of seasoning (airline flying), so that plays into it. I would certainly give Epic Insurance Solutions (www.epicinsurancesolutions. com) a try. I found them to be wonderful and they also provide the coverage for my other aircraft.

Likely the area of the aircraft that most people have an issue with is the landing gear rigging. But if you have it rigged properly—strictly per the maintenance manual—it’s not a problem. It’s actually a very stout gear.

I would say to anyone interested in a 310 that they should join The Twin Cessna Flyers. The information that I have received, both in locating an aircraft, as we’ll as operating and maintaining it, has been invaluable. I would also talk with the folks at TAS, arguably the premier Twin Cessna maintenance facility in the country. They’re located in Defiance, Ohio, and they have been extraordinarily helpful.

Rick Ferrin

via email

Since 1981, I’ve owned four 310s, two of them being the R model owned in the 1980s, one of them being a 1957 model owned in the 1990s, and the 1956 model I own now, N5267A. I also helped manage and flew a 310R from 2000 to 2009 for two non-pilot business partners.

I admit I am partial to the straighttail classics. Why the 310? With the R model, my wife and I, along with our two 200-pound sons and 200 pounds of luggage and scuba gear, flew nonstop to a dive location over 500 miles away in just over three hours and still had 1.5 hours of fuel left for full cruise power.

My 1956 model can easily handle four full-sized adults, each with a typical airline-legal carry-on suitcase, and go 400-plus NM with IFR reserves. With just me and my wife, we can take all the gear we want, plus fill the auxiliary tanks and easily add another 200 NM to that nonstop range.

My R models typically trued out in the 180- to 190-knot range, with chock-to-chock fuel burn rates of around 25 GPH. My 1956 model regularly trues out at 170 to 173 knots while showing a block fuel consumption of 21 GPH. Any 310 is a rock-solid flying machine, great on instruments and a nice short-field performer, especially with VGs.

The biggest mistake first-time legacy twin buyers make is thinking that just because these planes can be bought for nearly a song, that they will be equally cheap to operate. Parts and labor will be as much, if not occasionally more, as a $1.3 million new Baron.

You must also build your support network of mechanics who truly know the airframe. And as with most other legacy GA aircraft in today’s market, what you invest in it now won’t be what you realize on resale. But when you consider that for under $100,000, you can have a showpiece 310 that will run with new birds costing seven to ten times as much to buy, that resale depreciation point is moot.

If you go into 310 ownership with the mindset that you are spending this money on the airframe and upgrades because it’s what you want now, rather than worrying about the next owner and resale, then you will be rewarded with many years and flying hours of what I think is one of the best and most plentiful twins general aviation ever offered.

Guy R. Maher

Cleveland, North Carolina

I bought a mid-time Cessna 310R a few years ago as my first twin-engine airplane and it has been a love-hate relationship. I love the performance because I can pretty much count on 185 knots without it even breathing hard, and that’s with both engines pulled back enough (LOP) to not eat my lunch on the fuel burn.

It’s also an incredibly comfortable traveler. I normally load the right seat with my wife and one rear seat with our teenage son. I remove one of the aft seats to better accommodate bags and other stuff we travel with.

As for the hate part, the maintenance is intensive compared to my Saratoga. Cylinders, landing gear issues, exhaust, autopilot—you name it. Buyers need to understand this going in. It’s a complex but very capable twin. You’ll pay to play.

Larry Cherenski

via email