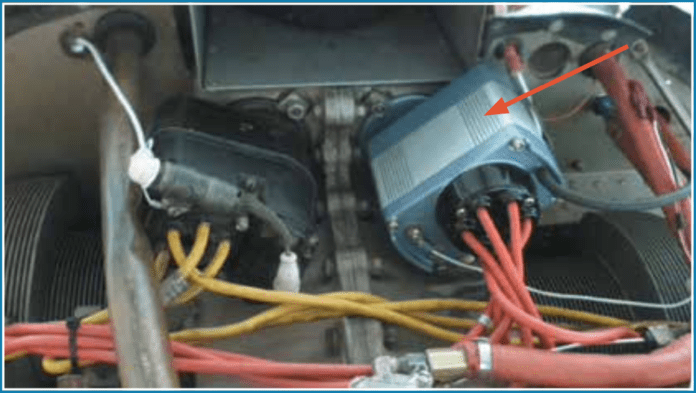

Pilots all over aviation social media have been touting the SureFly Ignition Module (SIM) mag replacement as the electronic ignition system of choice—and for some, it may be the best choice because of its simple installation. (That’s a drop-in SIM mounted next to a traditional mag in the photo to the right.) However, I’ve seen a lot of forum posts from misinformed buyers who simply overlook the additional benefits afforded by the Electroair ignition. (That’s a complete Electroair kit shown in the bottom photo.) One technical aspect focuses on the Electroair’s coil pack and high-energy spark. When I mentioned my more efficient starts, Electroair’s Mike Kobylik reminded me that the EIS 41000 ignition on my Grumman’s Lycoming delivers roughly 70,000 volts to the spark plugs, with a duration of 20 degrees crank rotation.

Moreover, the timing in an Electroair system is varied based on the manifold pressure sensor, which is a good way to measure air volume inside of the cylinder. You need to have both elements—high energy and variable timing—in order to achieve Electroair’s claimed performance gains.

Since SureFly’s electronic mag replacement uses the engine’s original magneto harness for delivering the energy to the spark plugs, that would suggest that the energy output from the SIM isn’t a lot different from the magneto it replaces. Consider that magneto harnesses use a 7-mm wire that has an outer metal shield. In a high-energy ignition system, this kind of spark plug wire will break down quickly and will arc internally, potentially causing audio system noise. The automotive industry went away from externally shielded wires several years ago when high-energy ignitions were first introduced. This is why Electroair supplies the 8.5-mm spiral-type wires that have a substantial noise suppression characteristic.

High-energy spark is critically important in aircraft electronic ignition systems because as the aircraft goes up in altitude and the air density decreases, the ability to ignite the fuel/air mixture becomes more difficult. A higher-

energy ignition source ensures a complete ignition of the fuel/air mixture at both high and low altitudes. The SureFly SIM has two specific limitations on its STC that can give us some insight into how their system operates. The first one is the requirement to have a digital engine monitor to use the timing advance feature. This could suggest FAA concern that the SIM’s timing advance needs to be closely monitored to keep temps in check and ultimately prevent the engine from suffering from detonation—a limitation that’s not in place with the Electroair ignition. The second major limitation of the SureFly system is it can only be used with 100LL fuel, presumably because of detonation concerns. This is certainly one of the problems that magnetos run into when using lower-octane fuels in higher-compression engines (think big-bore Continentals). Detonation with high-energy ignition systems (and a properly tuned and operated engine) generally isn’t a problem, according to Electroair.

Last, SureFly hasn’t claimed any appreciable fuel savings or performance issues that I’m aware of. I know from over 1000 hours of flying with the Electroair electronic mag on my Lycoming O-360 that I can consistently operate at least one gallon per hour lower than the fuel flow values listed in the aircraft’s original POH. Still, for a stone-simple installation and elimination of magneto maintenance, the drop-in SureFly SIM mags have sizable appeal. But it just isn’t a fair comparison putting them head-to-head with Electroair when it comes to performance gains. Worth mentioning is that I reached out to SureFly for comment and to learn more, but as of press time, disappointingly, the company hadn’t returned my several calls or emails. We did talk with them for the ignition article in the June 2022 Aviation Consumer.

—Bob Reed