Cross-armed, foot tapping, scowling aviators have been demanding electronic ignition for production aircraft engines ever since it became apparent in the automobile world that it increased power and engine efficiency and made starting easier. Plus, they don’t like having to yank magnetos for inspection, repair or replacement every 500 hours of engine operation—something not necessary with electronic ignition.

The good news has been that electronic ignition was developed to replace one mag on production aircraft engines several years ago—and the units have proven reliable in service while improving fuel efficiency and boosting dispatch reliability.

REPLACING BOTH MAGS

The better news is that one company, Waterford, Michigan based Electroair (www.electroair.net), recently completed a long, complex process for approval to replace both mags with electronic ignition in most general aviation airplanes. In addition, Electroair also received an STC for its electronic ignition unit that replaces the Bendix single-drive “dual” magneto on a number of Lycoming engines.

Another company, SureFly (www.surefly.aero), builds an STC’d electronic ignition unit it refers to as SureFly Ignition Module (SIM) that is approved to replace one magneto. It is currently seeking STC approval for dual magneto replacement.

WHAT’S THE BIG DEAL?

Before we go into the details, we’ll first discuss how electronic ignition works (and its advantages over magnetos), then move into why only single-magneto replacement was allowed for certificated aircraft until April of this year, move on to the performance benefits of electronic ignition and finally look at what is offered by Electroair and SureFly.

General aviation has relied on magnetos because each has a self-contained power source and they have generally proven reliable over the decades if they are pulled and inspected, repaired or replaced every 500 hours of service. After 500 hours, the moving parts tend to wear and certain failure modes can lead to firing the spark plugs at the right time to destroy an engine in a matter of seconds.

In addition, they aren’t particularly efficient. By design, they fire the spark plugs at the same point of engine rotation every time—usually 25 degrees before top dead center (TDC) of the piston travel—and rely on the combustion event itself to reach maximum pressure in the cylinder by the time the piston reaches 11 to 17 degrees past TDC.

Magnetos put out a spark that is on the order of 12,000 volts, which sounds like a lot, but isn’t much more than adequate.

The automotive world gave us electronic ignitions that advance or retard the spark—adjust the position relative to TDC at which the plugs are fired—to substantially increase the power and efficiency of the combustion event. That’s important—the nature of the combustion event determines engine power output and fuel efficiency. Electronic ignition also can lengthen the amount of time the plug fires. That, combined with five times the voltage to the plugs—some 70,000 volts—creates a hotter, longer-lasting spark. That increases power output, reduces plug fouling and makes starting easier.

In general aviation, makers of electronic ignition first focused on the homebuilt world due to the high costs involved with obtaining certification for use on production aircraft.

Service experience showed that replacing one magneto with an electronic ignition unit gave 85 to 90 percent of the performance and efficiency benefits obtained when both magnetos were sent to the old magneto’s home. That proved significant in causing two companies, Electroair and SureFly, to pursue STCs for production airplanes.

Obtaining approval to replace just one mag would be a far easier process than what would be involved in replacing two. That was primarily because the FARs require an independent power source that will power one of the electronic ignition units should the primary electrical system fail—and that independent power source had to meet some stiff standards on reliability and length of time it would function.

IN ACTION

When the single electronic ignition is doing its thing so that the timing is advanced and firing its set of spark plugs before the plugs fired by the remaining mag emit their spark, what happens? Is there a potential problem that there are two separate spark events?

The answer is unequivocally no. The electronic ignition has started the combustion event with some 70,000 volts of spark. Having the magneto-fired plug fire 12,000 volts at its normal time, during the ongoing combustion event, helps the event by a tiny fraction—and certainly doesn’t hurt it.

Because the mag-fired plug emits its spark during the combustion event the single electronic ignition system is sometimes referred to as a “wasted spark” system.

PERFORMANCE

Depending on the sophistication of the electronic ignition system installed, an owner can expect—at the most basic—an improvement in fuel efficiency of 10 to 15 percent (or a measurable cruise speed increase when burning fuel at the same rate). Performance and efficiency improvements with spark advance increase with altitude.

For the more sophisticated system—Electroair’s—there should be a measurable increase in rate of climb and service ceiling for the airplane.

As part of Electroair’s STC certification of a single electronic ignition system in six-cylinder Continental engines, it installed its system on aerobatic pilot Spencer Suderman’s Pitts S-2B; he was seeking to break the record for number of turns in an inverted flat spin. On his early attempts his climb topped out at 21,000 feet—not high enough to get enough turns on the way down.

With Electroair’s system, Suderman was able to climb to 23,000 feet, just over 10 percent higher. In addition, the engine developed more power so that Suderman lost less altitude during each turn in the flat spin. On March 13, 2014, Suderman set a new record of 98 turns in an inverted flat spin before recovering at 2000 feet AGL.

ELECTROAIR

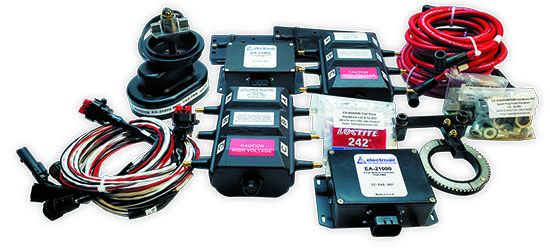

Electroair’s electronic ignition system (EIS) has four main components: a manifold pressure sensor, electronic control unit, direct-fire coil pack and either a mag timing housing (MTH) or crank shaft trigger wheel (CSTW) to time the ignition. The MTH times the ignition at the accessory case while the CSTW times the ignition at the propeller flange. Both methods work equally well—there is no difference in engine performance. The CSTW kit is significantly less expensive. However, there is not room for a CSTW on all aircraft for which the kit is approved. We were told by company principal, Mike Kobylik, that an owner who wishes to replace both mags must use two kits that contain an MTH.

A set of high-tension cable leads with terminals installed is provided with each kit—a standard ignition harness is not robust enough to handle the voltage.

Timing is picked up by either the CSTW or MTH, which provides a high-resolution signal feeding continuous RPM information to the dual microprocessor control unit. It receives RPM and manifold pressure information and advances the timing to compensate for altitude and throttle position based on proprietary and patented algorithms. Timing can be advanced as much as 20 degrees.

The direct-fire coils are the reason the system can produce 70,000 volts to the plugs. The spark produced lasts through 20 degrees of crank rotation—versus five for a magneto. The result is a much hotter, longer-lasting spark that improves starting, causes a more complete combustion event and reduces plug fouling. The aircraft owners we spoke with confirmed those claims.

If an owner is only going to replace one mag, Electroair recommends that it be used to fire the bottom plugs as they are more prone to fouling that the top set.

The Electroair system is available for over 400 types of aircraft and it seems the list expands monthly. Electroair’s website has a current list of approved aircraft.

Price for an Electroair EIS depends on whether it is for a four- or six-cylinder engine and whether it has a CSTW or mag timing housing. Prices range from $2,595 to $3,950. Electroair estimates two days for a four-cylinder installation—one day for the install and one day to confirm that everything is working properly and take care of paperwork—and three days for a six-cylinder install, with two days for the work itself and one day to take care of everything else.

Mike Kobylik repeatedly told us that before any work begins on an install, the owner and technician performing it should carefully review the installation procedure—on Electroair’s website—and put together an installation plan based on the specific airplane. Kobylik said that, because of mods and years of maintenance on legacy airplanes, components may have to be moved and there may be unexpected discoveries when opening up the airplane, such as corrosion, that will have to be dealt with.

Owners and techs are encouraged to call Electroair with questions. During business hours the company has experienced A&Ps ready to answer questions.

The tech we spoke with after he’d done his first install of a single mag replacement told us that going over the installation instructions carefully, before doing anything, paid off because much of the installation involves determining where to put components. He said that he called Electroair a total of three times during planning and the installation itself and got immediate, accurate answers to his questions.

GOING FOR TWO

While replacing both magnetos with electronic ignition has been almost routine in homebuilt aircraft, it has been a long time coming in certificated birds due to FAA policy and requirements.

According to Kobylik, the biggest challenge was a second, independent electrical power source so that one EIS continues operating without interruption should the primary aircraft electrical system even hiccup.

Kobylik said that the new STC provides three options to meet the dual power source requirement.

• The aircraft has a dual bus electrical system with two alternators. Examples include most piston twins, and in the single-engine world, the Cirrus line, Cessna TTX and Piper Malibu/Mirage line.

• A backup alternator where one EIS is wired directly into the backup so that it picks up the load immediately upon failure of the primary electrical system.

• A backup battery—the most common solution for single-engine airplanes. The backup battery includes a unit that monitors the primary electrical system (which is constantly providing a charge to the backup battery, keeping it topped off) and brings the backup battery online to power one EIS instantly if the primary electrical system fails.

An owner wishing to replace both mags buys two kits (that use the mag timing housing, not CSTW because there isn’t space for two CSTWs) and, if needed, the standby battery. Depending on voltage and ampere-hour capability of the battery selected, prices range from $1142 to $1617.

Because the dual mag replacement approval is so new, Electroair does not have installation time estimates, although Kobylik told us that it should be something less than twice the time it takes to install one.

BENDIX DUAL MAG

We’ve never been completely comfortable with the Bendix D2000/D3000 “dual magneto” used on many Lycoming engines. It is two independent magnetos packed into one box with a single drive shaft, mounted on a single pad on the accessory case. Accordingly, it has a single catastrophic failure mode.

In addition to receiving STC approval to replace both mags on a conventional-magneto engine, Elecrtroair just received an STC to replace the Bendix dual mag with a fully redundant, dual electronic ignition. We think that’s a big deal.

Price for a four-cylinder Lycoming is $4995; for a six-cylinder Lycoming it’s $6995. A backup power source, as discussed above, is required. The STC is too new for Electroair to have much information on installation time in the field. We think that four to five days would be a conservative estimate.

SUREFLY

The SureFly Ignition Module (SIM) magneto replacement is less sophisticated than Electroair’s EIS as it only advances the timing during cruise operations and only by a fixed amount—it does not vary with the variables that Electroair takes into consideration—so it is less expensive and requires less time to install.

It provides fuel savings of 10 to 15 percent in cruise, but SureFly makes no claims of increased climb performance. It is available for a wide variety of normally aspirated Lycoming and Continental engines (no turbos). It cannot be used with a mogas STC as can the Electroair system.

One of the important goals of SureFly in developing the SIM was ease of installation. We think they hit that one out of the park.

A SIM is nearly the same size and weight as a Slick magneto and a couple of pounds lighter than a Bendix. It mounts to the engine the same way a magneto does with a power wire, ignition switch P-lead and manifold pressure connection. The engine’s RPM signal is picked up within the SIM from the crank gear.

The SIM is adjusted to a particular engine’s base timing advance by a switching module accessible through a port on the case, so that the SIM “knows” how far to advance the timing in cruise operation.

The SIM provides more voltage to the spark plugs than a traditional magneto. Each spark plug has its own dedicated coil, virtually eliminating coil failures. While more spark energy is provided, it is not so much that it requires a specialized ignition harness, although SureFly requires the use of a Slick wiring harness.

Service life of a SIM is 2400 hours. We were told that the SIM was designed to last throughout the TBO of the engine for which it’s installed and there should be no downtime for inspections and no messing with the timing or risking the possibility of failures due to inspections and adjustments as are required for magnetos.

In speaking with our local shop, we found that installations have been running at four hours or less to take care of everything, including paperwork. We watched the installation video on SureFly’s website and were impressed at how straightforward it is. There are no remote boxes or additional components to install.

Below 400 RPM, timing is set to TDC, with a longer dwell and increased voltage for easier starting.

We noted that Lycoming is now offering its engines with an electronic ignition system instead of one mag. While the box reads “Lycoming,” it’s a SureFly SIM.

When deciding which magneto to replace, SureFly recommends that it be the one equipped with an impulse coupler. That’s because it eliminates the risk of impulse coupler failure and improves starting.

Price for the four-cylinder SIM is $1595; for the six-cylinder unit it is $1895.

We consider the SureFly SIM magneto replacement to be a simplified, maintenance-free ignition system without points, condenser, rotor and cap that provides, as a bonus, an increase in fuel efficiency in cruise.

CONCLUSION

We think that replacing at least one mag with an electronic ignition system has become a no-brainer. It gets rid of the maintenance for one mag as we’ll as the risk of catastrophic engine failure should that mag fail in just the right fashion.

The fuel economy improvement with SureFly makes sense and, if desired, especially with big-bore engines, going the extra mile to install one or two Electroair EIS units could pay big dividends over time.