Piper’s PA-28R Arrow series has long proven its versatility. We’ve trained in Arrows, we’ve traveled in them and we’ve wrenched them, too. No, these airplanes won’t break any speed records, although turbocharged models move right along in the sweet-spot higher altitudes. That makes them worthy for travel. For pilots moving into the world of complex retracs, for years the Arrow has been a go-to airplane.

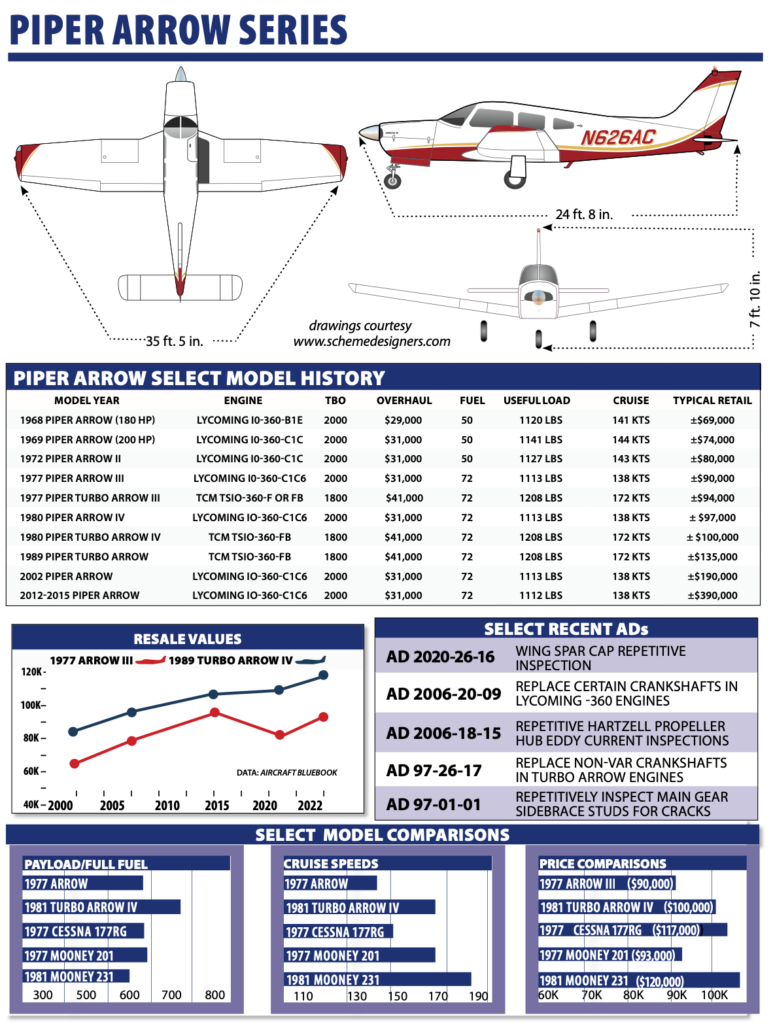

While the training market has certainly changed since the first Arrows hit the market, the airplane soldiers on. From the original, relatively sedate 180-HP version with its short, stubby wings to a fire-breathing, T-tailed, turbocharged version perhaps best known for heat-management and runway-hogging issues, there are plenty of models to choose from on the used market. All are up in value.

MODEL HISTORY

When it was rolling along back in the day, the original Cherokee did well, and was soon joined by the 180 and 235, giving Piper a strong lineup of fixed-gear singles meeting many missions. Since all Cherokees share the same basic airframe, the company was also able to realize some manufacturing economies.

By the mid-1960s, Piper began considering the PA-28 as a candidate to compete in the light four-place retractable market, then dominated by Mooney with Beech’s least expensive retractable—the Debonair—costing a third again as much as a Mooney. Cessna had no comparable airplane at all, and Piper’s Comanche would go out of production in the mid-1970s.

So, Piper folded the gear on its Cherokee 180 and in 1967 unveiled the first Arrow. It was every bit a Cherokee, from the fat, constant-chord Hershey Bar wing to the stabilator. The base price was $16,900, and the average equipped price of an Arrow, as delivered, was actually about $2000 more than the Mooney. To contrast, a Cherokee 180 from the same year had a base price of a mere $12,900.

The PA-28R-180 came with a constant-speed prop slung by a Lycoming IO-360-B1E engine. The new retractable gear was electromechanical (compared to Mooney’s distinctive manual “Johnson bar” arrangement), and had a unique feature designed to enhance safety: an auto-extension mechanism that would lower the gear if the airplane slowed below a certain airspeed. More on the landing gear system in a moment.

The original Arrow compared we’ll with the Mooney in some departments, such as roominess and cost, but fell short in terms of speed. Cruise was pegged at 141 knots, compared to 158 for the Mooney. Still, the Arrow was considerably faster than the carbureted, fixed-gear, fixed-prop (but otherwise identical) Cherokee 180. Plus, the Arrow was an easy transition for pilots coming out of fixed-gear Cherokees.

The 180 Arrow wasn’t a speed demon, and after two years and sales of almost 1100 airplanes, Piper came out with a 200-HP version. An extra $500 bought pilots a Lycoming IO-360-C1C engine, a few knots and a 100-pound boost in gross weight, though that was eaten into by a 79-pound increase in empty weight. The -C1C engine was more costly in other ways, too—it had a 1200-hour TBO, compared to 2000 for the 180. That short TBO has since been lengthened by fitting new exhaust valves, and it’s highly unlikely that any of the 1200-hour mills remain. The 200’s TBO is now also 2000 hours.

It’s no surprise that the 200-HP Arrow was sufficiently more popular than the 180 that the latter was dropped in 1971. Starting with the 1972 model year, the airplane was redesignated the Arrow II. Its fuselage was stretched five inches, providing more rear-seat room; its wingspan increased 26 inches by widening the Hershey Bar design and the stabilator’s span increased. This allowed 50 pounds more gross weight, and the addition of the long-awaited manual gear-extension override. Thanks to larger bearing dowels, the old 1200-hour TBO was boosted to 1400 hours. The next year marked the development of a redesigned camshaft and another TBO increase—to 1600 hours.

In the mid-1970s, Piper revamped its line of metal singles (leaving the Super Cub alone), starting with the bottom of the PA-28 line. Beginning in 1975, the airplane that had been the Cherokee 140 became the Warrior, sporting a new, semi-tapered wing of higher aspect ratio than the familiar Hershey Bar and a 150-HP engine. This new wing found its way onto the Arrow in 1977, creating the Arrow III. In that same year, Piper made a turbocharged version of the Arrow.

The new wing improved performance somewhat, most notably in terms of glide. It also gave pilots a healthy 24-gallon increase in fuel capacity—better for going places.

The Arrow III lasted only two model years. In 1979, Piper made a controversial design decision, opting to follow the T-tail design fad. This was dubbed “Arrow IV.” Predictably, performance suffered. Like many T-tail airplanes, the Arrow IV flies differently than Arrows with conventional tail feathers. Avoid jumping in one without transition training.

The T-tail, depending on airspeed, is either very effective or far less effective than a conventional tail (which isn’t as prone to abrupt transitions between different flying regimes). This occurs because the stabilator sits up out of the propwash, and so is less effective at low airspeeds. As a result, we’ve heard some pilots complain that the Arrow IV has squirrelly low-speed performance, with a tendency to over-rotate on takeoff. Our experience flying both is if you don’t try to fly the Arrow IV like the earlier models, you might look more favorably upon the T-tail. Regardless, if you’ve flown both, you’ll see that the T-tailed version demands more attention to pitch trim when changing airspeeds. Make sure the electric pitch trim system works we’ll when shopping for these models as trim motors work hard.

During a downturn hiatus, the normally aspirated Arrow IV wasn’t built for model years 1983 through 1987—only the Turbo Arrow IV was available. For model years 1988, 1989 and 1990, conventional-tail, normally aspirated Arrows were made alongside T-tailed turbo models. The last three Turbo Arrow IVs were 1990 models; subsequent Arrows through the last of then all have conventional tails and no turbos. No Arrows of any flavor carry 1991 or 1993 model designations; this was the time when Piper was on the rocks, searching for a buyer.

Piper emerged from bankruptcy in 1995 as New Piper, a moniker dropped in 2006. The newest version—known simply as the “Arrow,” without any Roman numerals—is essentially an Arrow III, arguably the best of the bunch.

MARKET COMPETITION

When the Arrow was introduced, its only real competition came from Mooney’s early M20s. Other manufacturers soon realized the viability of the market segment, however, and it wasn’t long before other competitors appeared. Beech’s offering was the rather lackluster (though roomy) Sierra, while Cessna weighed in first with the Cardinal RG, then the Cutlass RG. Rockwell got into the small retractable business with the Commander 112, and Mooney upped the ante with the landmark 201.

The average equipped prices of these airplanes when new in 1977 (the first year all of them were offered at once) ran as follows: Arrow III: $50,320, Cessna Cardinal RG: $50,095, Rockwell Commander 112: $61,295, Beech Sierra: $53,594 and Mooney 201: $57,420. The latest Aircraft Bluebook puts a 2012 Arrow in the $330,000 range, and a 2019 at nearly $500,000.

The Mooney 201 runs away from the rest in speed and efficiency.

NO SPEEDSTER

You generally don’t buy an Arrow to go fast. Cruise speeds range from 130 (180-HP) to 143 knots (normally aspirated 200-HP T-tail) and as high as 170 knots for a turbocharged version flown in the teens. The normally aspirated Arrows generally burn 9 to 12 GPH, while the turbocharged versions drink about 14 GPH when pushed.

A Cessna Cardinal RG, Cutlass RG or Grumman Tiger will go as fast, while burning less fuel. And a Mooney 201, on the same fuel, goes the fastest. Still, the Arrow has a roomier interior than all but the Cardinal, and its useful load is the greatest: 1200 pounds.

The first two Arrows had somewhat limited range, thanks to their 48-gallon fuel capacity. Beginning with the taper-wing Arrow III, 72-gallon fuel tanks eliminated that problem. Tapered-wing Arrow owners report as much as 6.5 hours’ endurance, while Arrow II owners sometimes wish for larger tanks.

The Arrow handles much like any PA-28 (it feels a bit heavier), which is to say it’s fairly benign. Stalls are a non-event. The wing loading is lower than higher-performance retractables like the Bonanza/Debonair and Mooney, which means a less solid ride in turbulence and at lower speeds. However, that’s also a benefit during landing, where the airplane is pretty predicable when flown by the numbers.

Climb performance is competent, but unremarkable. The Arrow is not a STOL airplane, but it doesn’t eat up runway, either. During descents, the Arrow’s gear serves as an effective speedbrake. The gear extension limit is close to the cruise speed (which really says more about the cruise speed than it does about the gear), so descents aren’t the problem they are in slick airplanes like the Mooney.

CABIN AND ERGOS

From our experience, the Arrow’s interior is comfortable enough. Piper deserves mention for its seat design in later aircraft, which have a crashworthy S-tube design meant to progressively collapse and absorb energy during an impact. This same basic design is used in the JAARS bush-plane seat. Piper also gets crashworthiness kudos for installing a thickly padded glareshield.

Heating and ventilation are both quite good, unlike some other airplanes in the class, with lots of overhead and floor vents. Egress is not the best; we don’t like the single cabin door, especially when compared to the double-doored Cardinal RG, Cutlass RG, Commander 112 and the Beech Sierra. Further, the double-latch system can confuse passengers, particularly in an emergency: Be sure to brief them.

Piper chose long ago to put the engine gauges near the power controls, which makes a certain amount of sense except when setting and monitoring power on takeoff. We’d rather see the gauges up in the pilot’s line of sight where they’re hard to miss, although these days, big-screen engine monitors solve that wart.

UPKEEP: TURBOS AND GEAR

Is this a foolproof retrac? It was supposed to be. The Arrow’s automatic landing gear extension system was intended as a safety feature; Piper touted the Arrow as the perfect airplane for pilots transitioning to retractables. Many pilots and insurance underwriters embraced the gear system, with some insurers even assigning lower rates. Alas, the system isn’t perfect, and as it turns out, it didn’t prevent landing gear-related mishaps in the Arrow.

Also the Arrow’s automatic gear extension system is a good example of how safety features can spawn new hazards even while eliminating old ones. In high-power, low-airspeed configurations, the system could either delay retraction or lower the gear at an unwanted time.

Then there are Arrow pilots who lose their engines and decide to ditch with the gear up. Unfortunately, some forget to override the automatic extension system. The gear plops out seconds before splash-down—sending the Arrow head over heels. Savvy Arrow pilots learned early on to “pin” (override) the system to keep the gear retracted when doing any sort of max-performance work.

There is a second pitot tube, located on the left side of the cabin, for the automatic gear system. If it is equipped with pitot heat, it should be checked along with the primary pitot tube before flight, as more than one pilot making a high-speed, IFR descent through a thin stratus layer has had the gear suddenly extend because that second pitot froze over with ice.

There were enough “misunderstandings” by mid-1987 that Piper, then owned by Lear-Siegler, ordered the system deactivated because of concern over liability suits. It sold kits to do so, and told customers it wouldn’t provide parts to repair the existing system. Piper sold around 1400 kits.

A year later—then owned by M. Stuart Millar—the company withdrew its deactivation order, provided that pilots “take the necessary actions to assure that any pilots flying these aircraft are fully advised of the system and its proper operation.” In part, Piper was responding to the complaints of irate owners who believed the system worked often enough to be desirable.

When Piper hung a 200-HP turbocharged Continental TSIO-360-F onto an Arrow III in 1977, the combination looked like a perfect match: the world’s premier economy retractable single and a powerplant promising high-tech performance at low-tech prices.

The extra money—the average 1977 Turbo Arrow III went out the door costing around $4600 more than its non-turbo’d sibling—boosted book max cruise speed from 149 KTAS to a whopping 177 at altitude. A new cowling rounded out the deal and announced to the ramp rats your bird was turbocharged.

Soon, however, the engine began earning a reputation as tricky to operate and prone to self-destruction. It didn’t help much when, in 1979, Piper combined its T-tail airframe with the turbo’d engine, even if the powerplant got a different suffix and much-needed TBO extension (from 1400 to 1800 hours).

The result was a handful on the runway: The T-tail’s tendency to encourage over-rotation, coupled with the engine’s need for attention on the takeoff roll, meant a busy time, especially on high-elevation fields. On the good side: The engine’s fixed wastegate introduced legions of pilots to the term “bootstrapping.” For pilots transitioning from a normally aspirated Arrow, it was too tempting to run the throttle to its stop early in the takeoff roll, just as one would with the non-turbo’d version.

Do that with the Turbo Arrow, though, and you’d get a red “overboost” light very soon, often followed by your mechanic’s bill for the subsequent inspection. Instead, the favored technique was to run up the MAP to no more than 30 or so inches early in the takeoff roll, then forget about it while monitoring the other engine gauges and keeping the centerline straddled.

When workload permitted—or runway length demanded—and after the system spooled itself up to around 35 inches, a gentle nudge to the throttle gave around 39 or 40 inches, and then the engine likely would boost itself the rest of the way to its 41 inches of manifold pressure limit and off you went. In general, we didn’t have any problems with the ones we flew, although we did have a fuel primer button stick in flight, flooding the engine.

Alas, the engine wasn’t as bulletproof as Continental intended or Piper hoped. The NTSB reports over the years revealed powerplant failures. Moreover, the engine stoppages weren’t the result of typical pilot errors such as fuel mismanagement, fuel exhaustion, etc. They occurred from failed connecting rods or rod bolts, broken crankshafts and damaged pistons.

Things got so bad that the National Transportation Safety Board in 1985 called for an airworthiness design review of the engine, citing a litany of component failures. Then-FAA Administrator Donald Engen rejected the request.

These days, things have calmed way down with the Turbo Arrow. A recent check of Service Difficulty Reports (SDRs) going back into the 1990s did not uncover any real trends with the Turbo Arrow’s engine, airframe or appliances.

But there is the recent wing spar issue. The proposed Airworthiness Directive to inspect the wing spar on thousands of Piper PA-28 and PA-32-series aircraft (including retracs) has been finalized. As we reported last year, the AD was prompted after an Embry-Riddle Aeronautical University Piper Arrow lost a wing on a commercial checkride flight in Florida back in 2018.

The final ruling and prescribed compliance are written in AD 2020-26-16 and includes inspection for wing fatigue cracking in a visually inaccessible area of the lower main wing spar cap. Since this is stress damage, the inspection interval for a given aircraft is determined by calculating the factored service hours for each main wing spar.

Then, when an inspection is due, look hard at the lower main wing spar bolt holes for cracks. Worst case (other than actual failure) is having to replace a cracked wing spar.

Bottom line: When searching the used market for an Arrow, pay attention to the total time on the airframe—and its inspection history. The FAA writes in the AD that because training aircraft (subjected to high aerodynamic loads, presumably) are typically operated for hire and subject to 100-hour inspections, the number of 100-hour inspections completed on AD-applicable aircraft would be the best indicator of the airplane’s usage history.

Put a formula to the number of hours flown on the airframe and the number of 100-hour inspections completed to determine when an airplane meets the criteria for an eddy current inspection on lower main wing spar bolt holes.

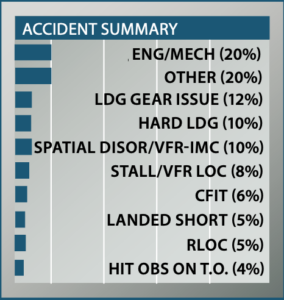

Our review of the 100 most recent accidents of the Piper Arrow series was significant for what did not turn up.

First, there were only two fuel-related accidents—an incredibly low number for a fuel system design in which the pilot has to select the tank to use. Plus, there were no fuel contamination events, a tribute to a good design that allows identification and removal of water in the tanks.

Second, there were only five runway loss of control (RLOC) accidents. We feel that is a tribute to the wide stance landing gear and good ground handling of all Arrows.

On the other side of the landing equation, there were 10 hard landing accidents—a number slightly higher than we expect to see. If not flown on speed on final an Arrow can bite. If slow, it can set up a significant descent rate that requires a willingness to flare assertively and/or add power to generate a smooth touchdown. If fast, an Arrow will float a long way, leading to impatient pilots forcing them onto the ground or PIO and a hard touchdown.

There were only two inflight breakups during the period—one in a thunderstorm—an indication that an Arrow is draggy enough that inflight LOC is recoverable before the airspeed gets unpleasantly high.

The other breakup was frightening and raised design concerns that the FAA is continuing to examine. It occurred in good weather. It was due to fatigue cracks in the lower spar cap of a high-time Arrow used almost exclusively for training and subjected to over four landings per hour of operation.

There were 12 landing gear-related accidents, just slightly higher than we expect to see. Seven pilots simply forgot the gear—distraction was a common theme in most. There were four gear collapse accidents. All appeared to be due to poor maintenance. One pilot did not have three green lights and made a fly-by. He was told that the gear looked to be down. He did not bother to run the emergency extension procedure or he might have found the popped gear circuit breaker. The gear folded after touchdown. Once the airplane was jacked up and the CB pushed in the gear operated normally.

We found 20 reports of engine power loss in flight, more than half of which were due to bad or unperformed maintenance. A mechanic who did a top overhaul put all eight hydraulic valve tappet plungers in backward. One intake valve broke in half soon afterward, causing a forced landing.

Another technician installed the wrong oil quick drain during an annual. When the gear came up it hit the valve, opening it and draining the oil. Engine seizure and a forced landing followed.

One pilot had the engine lose power when he shut off the aux pump after takeoff. He turned it back on, power returned and he returned to land but couldn’t seem to line up on a runway. He put the airplane into a field but suffered a life-threatening head injury because he hadn’t bothered to wear the shoulder harness part of his seat belt. Interestingly, he was under a court order not to fly any airplane and was to surrender to authorities that day to begin a prison term.

TURBO MODS

One of the reasons for the Turbo Arrow’s recent reliability may be the aftermarket mods available. Two are significant: intercoolers and an automatic wastegate. Turboplus (www.turboplus.com) and Airflow Systems (www.airflow-systems.com) offer intercoolers.

At 12,000 feet, the Turbo Arrow has a fairly low critical altitude—the max altitude at which the engine will develop its rated horsepower. Owners say they get a higher critical altitude with the intercoolers, along with lower operating temperatures.

Meanwhile, in an effort to prevent bootstrapping on the Turbo Arrow and other aircraft with the TSIO-360 engine, Merlyn Products (www.merlynproducts.com) has taken an even more dramatic step and come up with an automatic upper deck controller that looks like the answer to a prayer for Turbo Arrow owners. It increases the critical altitude by 5500 feet while boosting cruise climb and speed slightly, and lowering CHT and oil temperatures significantly.

The ostensibly nifty benefits of this system are much lower turbo speeds, lower engine RPM settings at all altitudes and generally allowing lower engine operating temperatures.

OWNER COMMENTS

For the last 18 years I have owned and operated a 1979 Arrow IV. The aircraft has taken us away to many destinations over the years and continues to provide us an escape to reach isolated destinations in these pandemic times.

My Arrow IV went through a complete panel upgrade three years ago and is now equipped with Garmin GTN 750/650 navigators, GTX 345 ADS-B transponder, G5 EFIS, GPS 796, S-TEC 55X and more. It is a dream to fly and the newer avionics make IFR flying safer and more manageable. I typically flight plan for 135 knots and burn 9 GPH. It’s no rocket ship, but my trips are typically up and down the East Coast. The larger 78-gallon (72 usable) fuel tanks make five-plus hours of cross-countries very doable.

Insurance costs have skyrocketed and my premiums for a $1 million smooth and $160,000 hull policy is $2700 a year. Aircraft values are through the roof and it’s hard to believe what aircraft are selling for these days.

My annual-inspection costs average around $3000 per year, and factoring the overall costs with hangar, insurance and navigation databases it’s safe to add another $7000. I budget $13,000 per year before fuel costs.

My last annual inspection bill was huge but that was due to a new shop that found items that were overlooked by the previous shop. It was money we’ll spent in my opinion. Dispatch reliability has been solid, and only once was I stranded due to a twisted alternator belt. The belt had to be overnighted in and then we were on our way.

The T-tail used to be a controversial topic, but for those of us who fly this aircraft we know better. It is a solid ship and should not be passed over when shopping.

Andy Elwood – via email

I purchased my 1971 Arrow II, N994BC, in 2007. The previous owner was a corporate aviation department where the plane served alongside a Bell Jet Ranger and a Gulfstream. They outfitted it with (then) state of the art avionics, including a Garmin GNS 530 interfaced with an S-TEC 55X autopilot with all trimmings, plus they renewed everything firewall forward. I installed an Electroair electronic ignition in place of one magneto. Along with the expected improvement in power at altitude (due to variable spark advance) it has made the engine much easier to start.

It’s a very efficient cross-country machine for two people and modest baggage, and perhaps a small child or pet in the back seat. I fly it LOP, which gives me about 135 knots at 9 GPH at its most efficient altitudes between 5000 and 8000 feet. Fueled with 50 gallons of fuel is fine for VFR legs, but a bit constraining once you subtract IFR reserves. You’re not going to overfly large weather systems. If you’re over six feet tall or want more fuel, consider an Arrow III or a IV with the longer fuselage and the bigger tanks.

One distinctive feature of older Arrows is the Hershey-bar wing. I show off its performance to other pilots by demonstrating simulated power-off landings, where the aircraft has approximately the glide performance of a Space Shuttle orbiter. You don’t want to get behind the power curve!

My airplane has been generally very reliable. It does eat batteries at a good clip—maybe due to all those avionics? One trouble area is the brake system. I’ve had two failures, one with a leaking connection and the other with the parking brake master cylinder. Each of these resulted in near-zero braking performance. This system is not like your family car where the brake pedal and the parking brake are separate systems—on the Arrow it’s a single hydraulic loop, including pedals and parking brake. A brake check right out of the parking spot is essential. Add it to the checklist.

Cost wise, I calculated an hourly rate of $125 with reserves when I started out, and I saw the reserves building up acceptably until about 2016 at which time they started a descent. Reserves are nearly gone by now. Realistically this 50-year-old airplane is going to cost more to maintain than it did, and of course the prices of gas and parts are climbing at a good rate. With fixed costs included, I calculate I’m paying close to $300 per hour for my 40 hours of flying per year.

Jeremy Jacobsohn – via email

I might be a rare beast but I bought my 1969 Arrow I, G-CKLI (I am in the U.K.), as my first plane because I wanted a capable IFR platform that could reasonably cruise with three or four people onboard.

The aircraft cost £45,000 ($59,400) after discounting for the upcoming annual, which was predicted to cost £4000 ($5280), but once I have upgraded the lights to LED it will be £5000, or $6600. This of course isn’t normal as there were some corrosion issues, but they were small, an issue with the elevator bracket which we replaced and a reasonable list of items we wanted to clean up.

I am averaging around 10 MPG and could probably get that lower with some sacrifice on speed. One instructor who did my complex conversion was surprised that we comfortably got 130 knots (indicated) in cruise.

As for the engine, whilst around 400 hours from overhaul is reliable and runs well, there were some small issues found at the annual with seals and such, but they were addressed—nothing major at all.

In addition, I intend to spend quite a bit of money on avionics upgrades. She needs to be brought up to date so I’ll be installing a Garmin GTN 750 GPS, a Garmin audio panel and a Garmin GI 275 EFIS. Later we will remove the vacuum system and add three more GI 275 electronic flight instruments and a Garmin autopilot.

Chris Bannocks -via email

My 1969 Piper Arrow 200 generally cruises at 155 knots above 6000 feet, burning 12 GPH. My hobby is to load a bicycle in and ride on trails near the airports on the coast.

I’ve had to remove all of the passenger seats to get my full-sized road bicycle to fit in the cabin, but it’s worth the effort. Although it’s not cosmetically perfect, the aircraft seems quite reliable. It only has a single yoke-mounted GPS—no glass displays or other fancy avionics. It’s just a basic aircraft that suits my 200-hour yearly flying.

Allan Weller -via email