Were not sure if its a good thing or not, but the dry vacuum pump-arguably the most exasperating component aircraft owners have to tolerate-has been on the hot seat lately. A high-profile crash in which a failed pump was hinted (the Governor Mel Carnahan crash four years ago) has stoked owner nervousness about instrument back-up systems and in parallel, several improvements in dry pump technology have found their way to market.

Now comes the Airwolf Filter Corp. with bold plans to end run around the dry pumps foibles entirely by reviving what used to be the standard source of instrument vacuum: the engine-driven wet pump. There are still plenty of these in service but their number has been dwindling because until Airwolf re-entered the market this year, no one built new wet pumps and overhauling the older pumps, mostly Pescos, has proved challenging due to lack of parts.

But Airwolf is gearing up to reverse that and now announces that it has wet-pump PMA approval for any airplane that uses a dry pump for a vacuum instrument system. For aircraft with pressure systems-Beech products-Airwolf can provide an STC to convert them to vacuum systems.

At $1895, an Airwolf wet pump is four times the cost of what we consider to be the best dry pumps, plus the cost of an air/oil separator, which we predict most owners will want. (Airwolf has revived the Walker air/separator and sells it for $495). Airwolfs John Kochy is so bullish on the wet pumps reliability, the company is offering an all-but-unheard-of warranty: 10 years or 2000 hours. (Thats close to lifetime warranty support in some fashion, since the pump has a 2000-hour TBO.)

How It Works

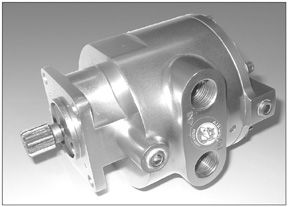

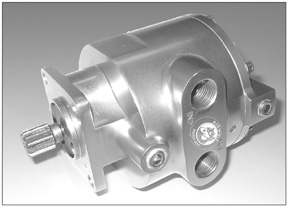

Airwolfs new pump is based on the old Pesco design but has a number of improvements, according to Kochy. Wet pumps owned the instrument air market until sometime in the 1960s when, according to industry lore that may or may not be accurate, dry pumps overtook them by dint of being easier to build and, more important, cheaper. They were also cleaner because wet pumps draw a tiny volume of engine oil for lubrication and expel this overboard where it inevitably coats the belly unless the airplane is equipped with an air/oil separator to condense the oil and return it to the sump.

Like a dry pump, a wet pump makes vacuum by rotating vanes or blades inside a cylinder-like casing. The vanes are contained in a slotted rotor riding on massive bearings. But where the vanes in a dry pump are thin and brittle, a wet pump has larger, thick blades that are also softer and less shatter-prone. Because the tolerances between the blade tips and the polished surface of the case are tighter than in a dry pump and further sealed by a film of oil, a wet pump delivers up to twice the vacuum differential of a dry pump, according to Kochy. (The regulator steps this down to the appropriate differential for the instruments.)

Because of their more robust construction and oil lubrication-they use about 1 cc of oil per minute-wet pumps are known to be more reliable than dry pumps.Kochy believes failures are all but unknown, although the pumps do wear gracefully with use, delivering less vacuum as they age. The wet pumps most notable weakness is that dirty oil will foul it, possibly causing it to run dry and fail prematurely. Thats why the only conditions of Airwolfs warranty are that the engine be equipped with an oil filter and low-loss vacuum fittings that have gentle sweeps rather than hard right angles Upon reaching the 2000-hour TBO, says Kochy, the Airwolf pump will be rebuildable from an owner-provided core. The price of that rebuild hasnt been set yet but it will be less than the price of a new pump. Kochy is careful not to use the word overhaul. Rebuilt pumps will have new-limit tolerances, not service limits.

Economics

We agree with Kochys view that a wet pump is more reliable than a dry pump although we also suspect failures are possible. It is, after all, a mechanical device. Over the years, owners of wet pumps have consistently raved about wet-pump reliability and, admittedly, we have not heard of a single in-flight failure. But you’ll pay for that reliability, too. If installed with an air/oil separator-which we think is a must-plan on spending $2600 to $2700 to install a wet pump, a sum that will buy five dry pumps.

Stipulating that the wet pump is more reliable, what youre buying is insurance against unexpected in-flight failure, thus it may be reasonable to forego a back-up vacuum source or pro-active replacement of a dry pump as a means of assuring reliability. And since there’s plenty of volume/pressure differential, an inexpensive vacuum gyro can do back-up duty rather than a much pricier electric gyro.

In the wake of the Aero Advantage dual-pump fiasco (see Aviation Consumer, July 2004), were wary of new products making unproven claims. Although we don’t think Airwolfs wet pump has yet demonstrated that its the only solution for reliable instrument air, we also believe Kochys confidence in the wet pump idea isn’t misplaced and were impressed with its construction quality.

Further, Airwolf is an established company with a good record selling oil filter systems so were confident it will be around to honor its warranty and support the product. With that in mind, Airwolfs wet pump looks promising. Well have our editorial ear to the ground listening for owner experiences with the Airwolf wet pump.

Contact – Airwolf Filter Corp., 800-326-1534, www.airwolf.com.

Also With This Article

“Checklist”